Exhaust through the vent plug and vent valve of the mold

Exhaust through the vent plug and vent valve of the mold

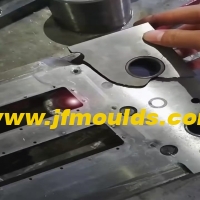

One: Exhaust through the vent plug

The exhaust plug is a mold accessory used inside the mold to expel air and other impurities, thereby improving the quality of the mold products. There are two types of materials for exhaust plugs as follows

1. Copper (special for hollow molds), with a hole diameter of 0.05mm

2. Stainless steel (specifically for injection molds), with a hole diameter of 0.03mm

Exhaust plug performance

The tiny exhaust holes can immediately expel the air or other gases inside the mold to the outside. It is simple and effective, which can improve the exhaust efficiency of the mold and effectively solve the following problems.

1. Charring: When the filling of the plastic melt is faster than the exhaust, the air is thermally compressed under pressure, and the hot melt accumulates at the front end, generating high temperatures, which causes the plastic melt to discolor and char.

2. Overflow: As the temperature of the resin at the front end of the joint rises and its viscosity decreases, overflow is prone to occur. In addition, if air causes filling obstacles, the injection pressure will rise, resulting in the mold slightly expanding and causing material overflow.

3. Insufficient filling: Although no charring or overflow occurred, the resistance caused by air slowed down the filling speed, resulting in insufficient filling.

4. Bubble silver lines: Air and resin condensation cause appearance defects such as bubbles, silver lines, and stains.

5. Extended injection molding cycle: If the resin temperature and mold temperature are increased and the injection speed is reduced, the injection molding cycle will be prolonged. Usage method: The vent plug and mold insert should be fitted with a tolerance of H7/s6.

Air valve exhaust (inlet

(1) Precautions for designing exhaust valves

1. It should be on the non-surface of the plastic part

2. It is set at the end of the joint line of the plastic part

3. It is applied in molds with relatively high quality requirements for plastic parts

4. As it will increase the mold cost, the exhaust valve is generally not used unless requested by the customer

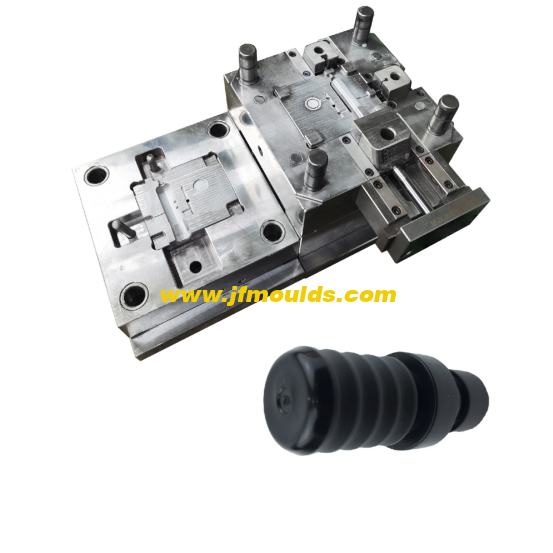

(2) Elastic rubber air valve structure

This structure can both exhaust and intake air. Between the air valve and the fixed mold insert, there is an exhaust slot originally named A. The value of A depends on the type of plastic, as shown in Table 5-1. When the melt is filled, the gas is discharged through the air inlet and outlet holes of the vent groove around the valve. When the mold is opened, the elastic rubber pushes the gas valve forward by 0.50 to 1.00mm. The gas valve pushes the plastic part to prevent it from adhering to the cavity of the fixed mold. At the same time, the gas enters the space between the plastic part and the fixed mold insert through the vent groove around the gas valve, allowing the plastic part to be smoothly detached from the fixed mold.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

(3) Spring exhaust (intake) valve

This structure is mainly used for air intake. That is, when the mold is opened, high-pressure gas enters the cavity through the fixed mold gas valve 2, pushing the plastic part off the cavity surface of the fixed mold and away from it. After the mold opening stroke is completed, the high-pressure air then pushes the air valve 4 of the moving mold, and the plastic can also be used for exhaust. The method is to evenly open exhaust slots on the conical surface where the air valve and the mold fit, and then push out the mold. This is a simple diagram of the exhaust valve for the tire mold without air holes, where the valve body is tightly fitted and embedded in the tire mold pattern.

(4) Tire mold exhaust valve

It is a simplified diagram of an exhaust valve for a tire mold without air holes. In it, the valve body is tightly fitted and embedded in the valve hole of the tire mold's patterned cavity. The valve core is installed in the central hole of the valve body, and the top of the valve core and the valve body are correspondingly provided with conical mating surfaces. An exhaust groove is provided between the two conical mating surfaces, and the conical mating surface at the top of the valve core is attached to the conical mating surface of the valve body through a pressure resistance structure.

Related News

Injection Mold Base Design (Part Two)

2025-09-27

Injection Mold Base Design (Part Two) One: Double pusher plate injection mo...

Mold drawing design standards

2025-09-09

Mold drawing design standards1. Add the shrinkage dimensions to the plastic part...

Solutions for the rubber powder and inner side scratches on the sprue of the mold

2025-09-03

Solutions for the rubber powder and inner side scratches on the sprue of the mol...

Treatment methods for mold weld marks/shrinkage marks and fractures

2025-08-09

Treatment methods for mold weld marks/shrinkage marks and fracturesMold weld mar...

How can the top white and surface elevation of the mold be solved

2025-08-26

How can the top white and surface elevation of the mold be solvedThe top white o...

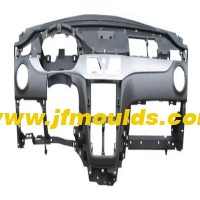

Plastic parts

2025-09-15

Plastic partsOne: Dimensional accuracy of plastic partsThe dimensional accuracy ...