Injection Mold Base Design (Part Two)

Injection Mold Base Design (Part Two)

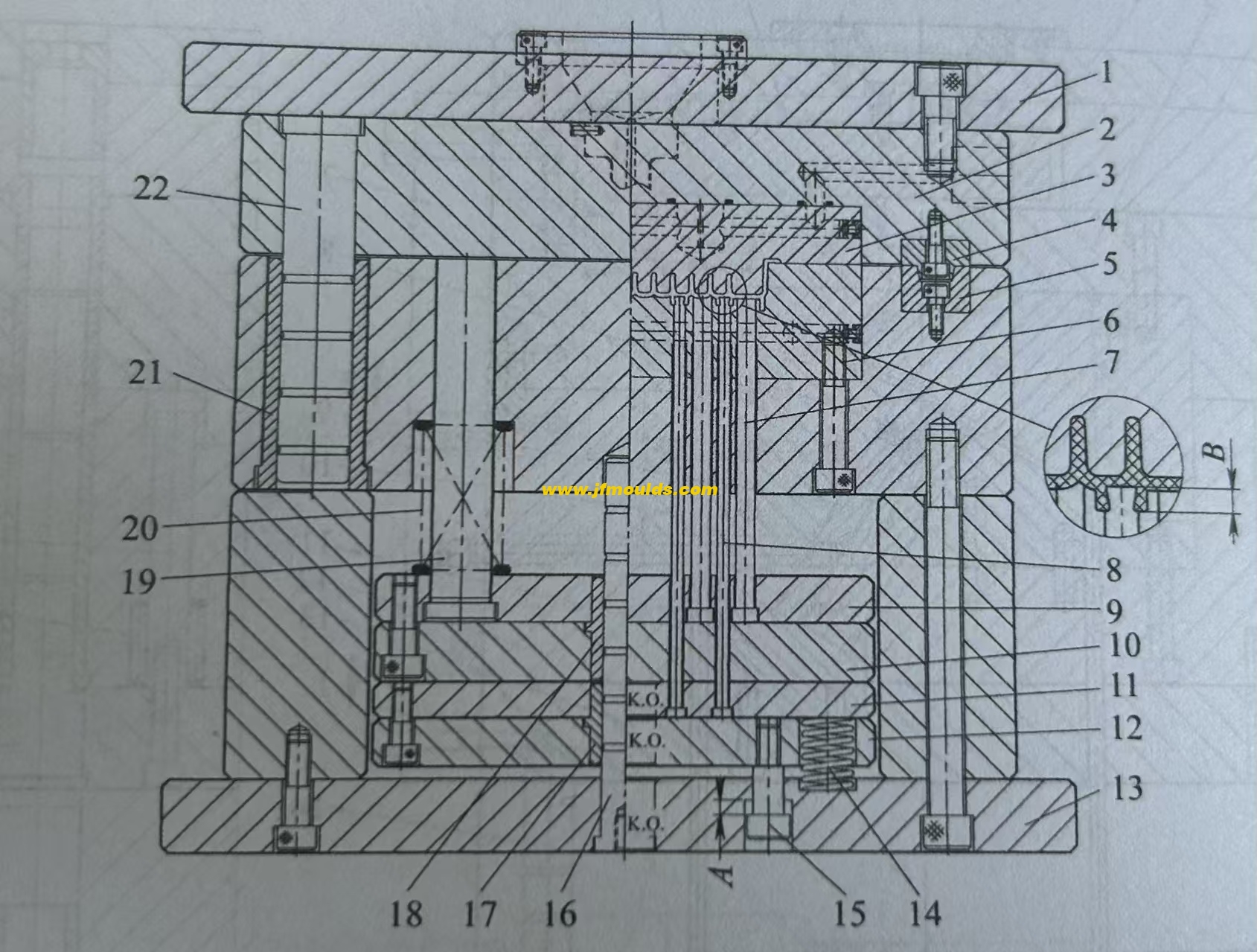

One: Double pusher plate injection mold

Double pusher plate injection molds are often used in situations such as forced demolding, secondary demolding or multiple demolding. The principle is: The movable core and the push rod are respectively assembled on two sets of push plates. After the mold completes one injection molding, the injection molding machine's top rod pushes the push plates. Under the action of components such as springs, the two sets of push plates and the movable core and push rod on them are simultaneously removed from the mold along with the plastic part. When the top rod is pushed A distance, the push plate with the movable core stops moving, while the push plate with the push rod continues to move forward. Push the plastic part away from the movable core.

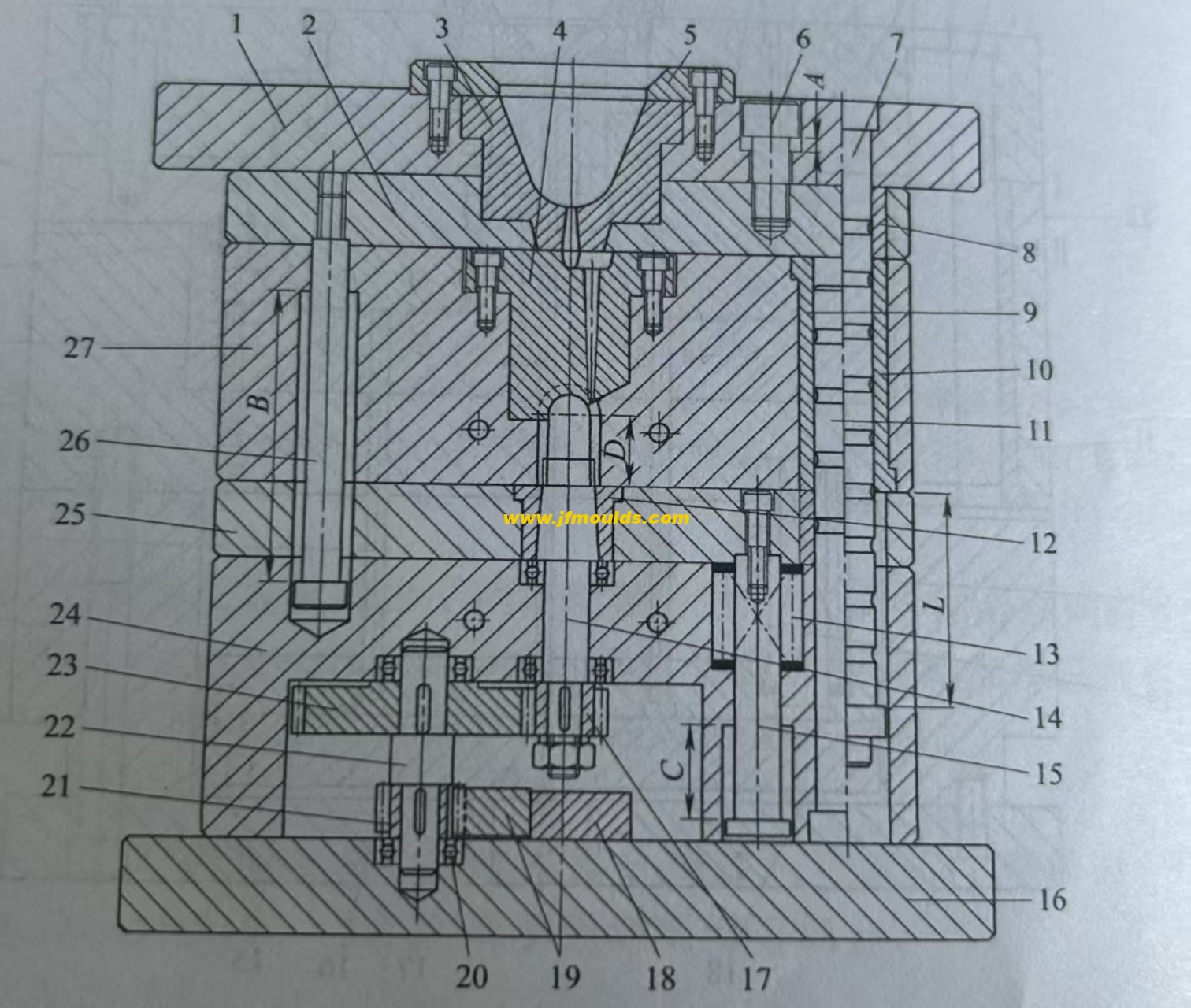

Two: Injection mold without push rod plate

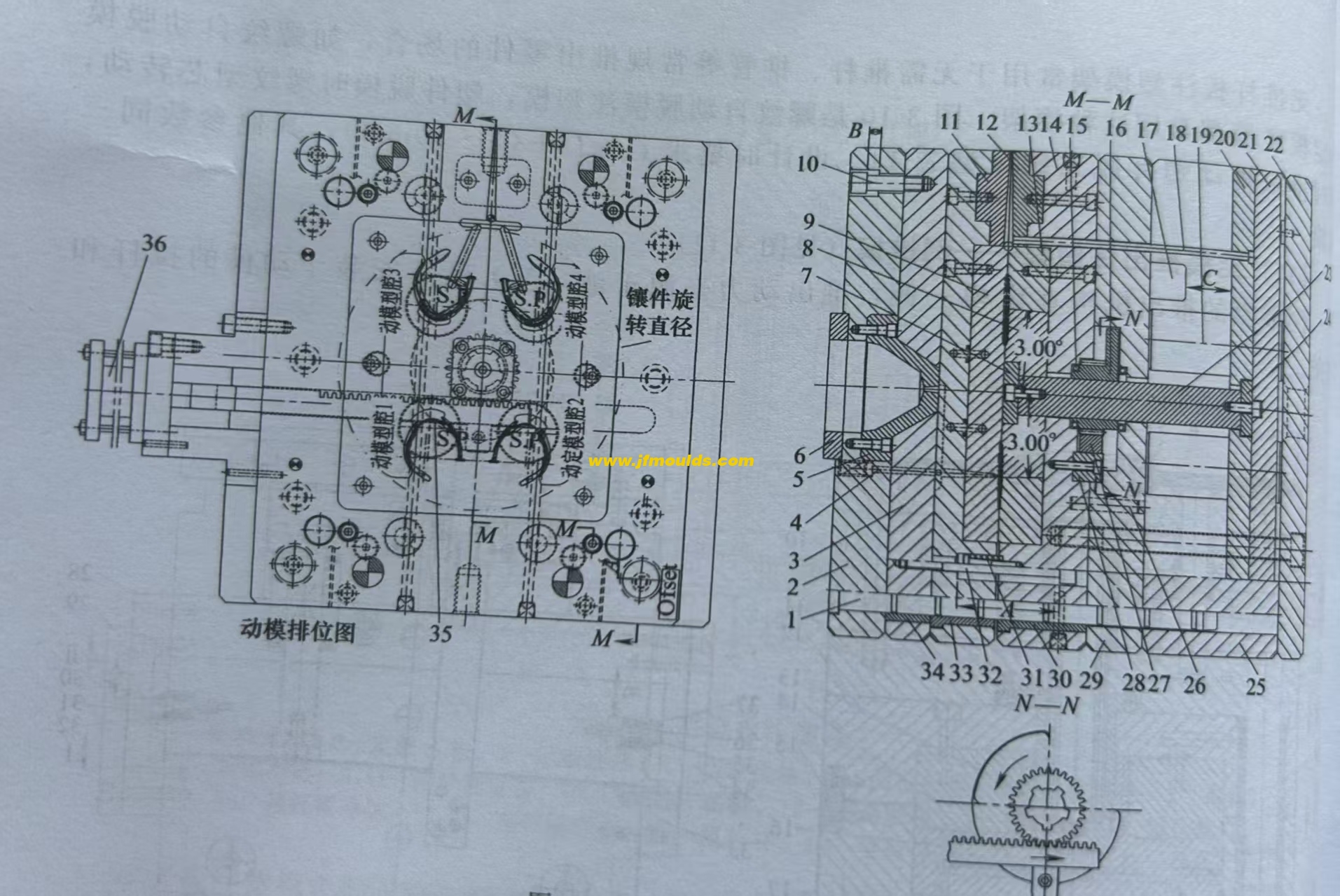

The injection mold base without a push rod plate is often used in situations where conventional parts ejection methods such as push rods and push tubes are not required. For instance, this type of mold base is commonly used in automatic thread demolding and fixed mold demolding. In the picture, the thread automatic demolding injection mold shows that when the plastic part is demolded, the thread core rotates, and at the same time, the push plate pushes the plastic part off the thread core. When designing, it is required that C=D+ (5-10mm). Other parameters are the same as those of the three-board mold.

Plastic washbasin injection mold Manufacturer in China (jfmoulds.com)

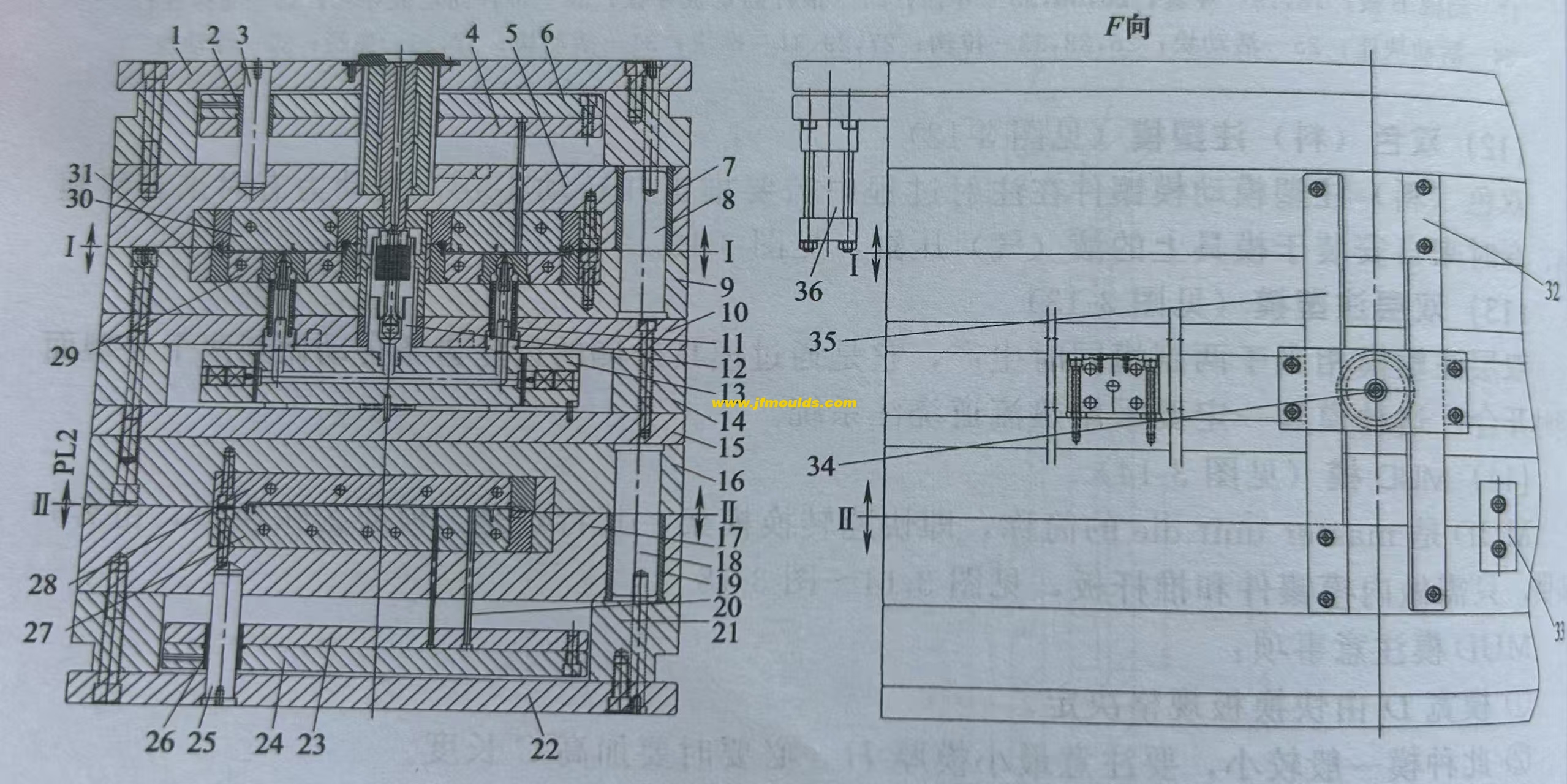

Three: Fixed mold ejection injection mold - reverse injection mold

The ejection mechanism of the reverse push die is on the fixed die side, and the ejection power comes from the hydraulic pressure, the pull rod installed on the moving die and the chain.

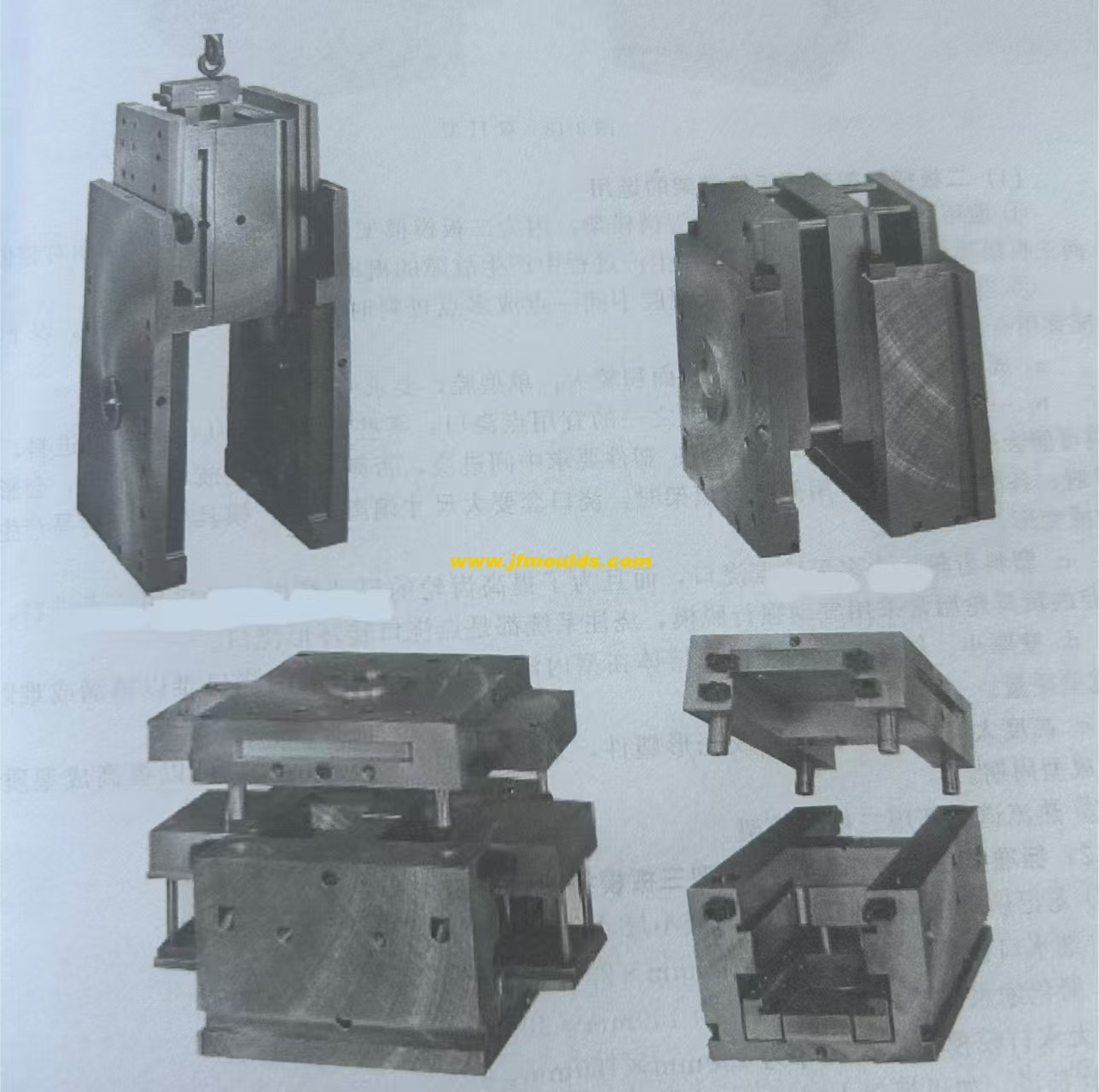

Four: Two-color injection mold

The moving mold insert of the two-color injection mold needs to be pushed out and rotated 180° during the injection process. The power sometimes comes from the injection molding machine and sometimes from the hydraulic cylinder installed on the mold

Five: Double-layer injection mold

A double-layer injection mold is equivalent to the simultaneous production of two molds. It achieves the simultaneous opening and closing of the two parting surfaces through the gear rack transmission on the outside of the mold. This kind of mold must adopt a hot runner gating system.

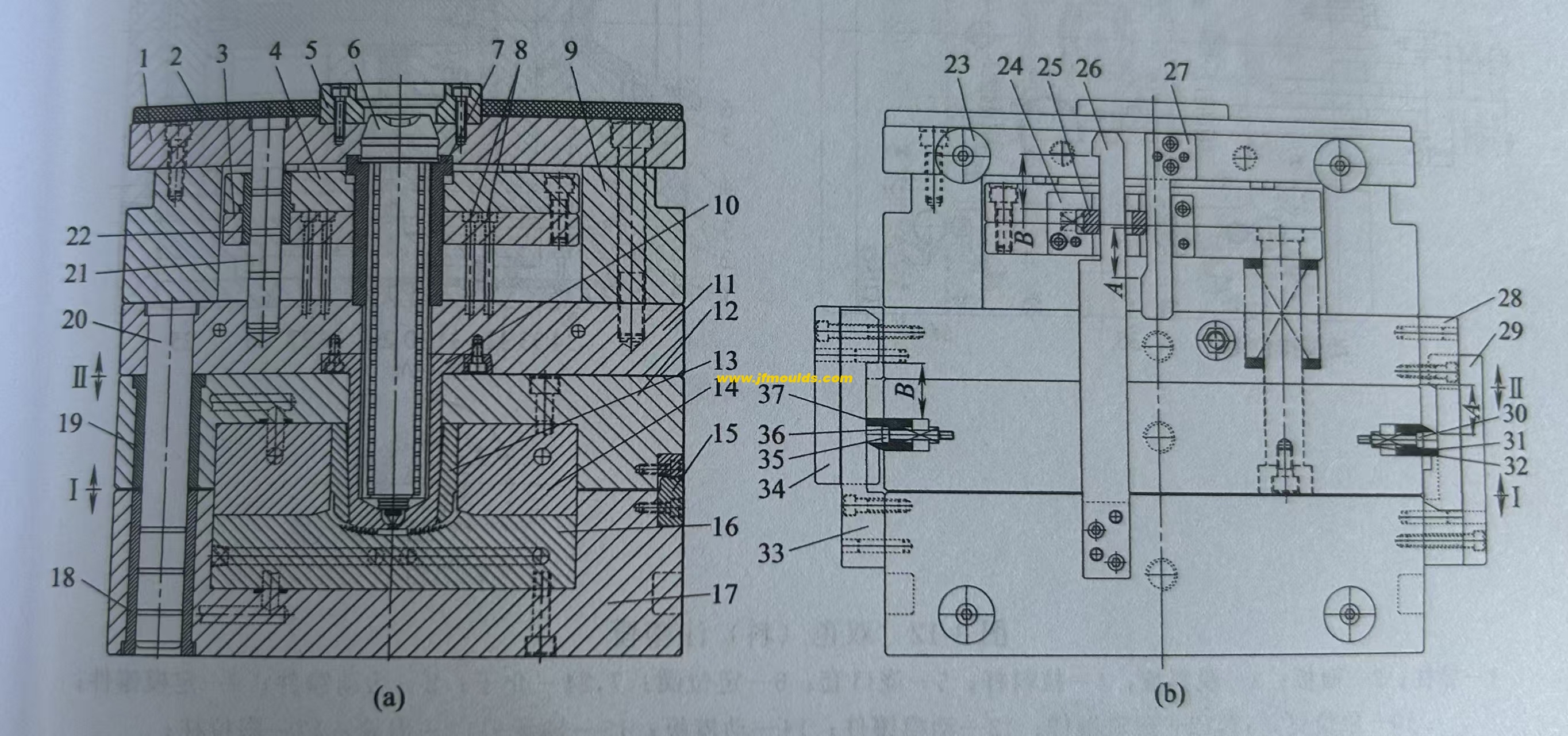

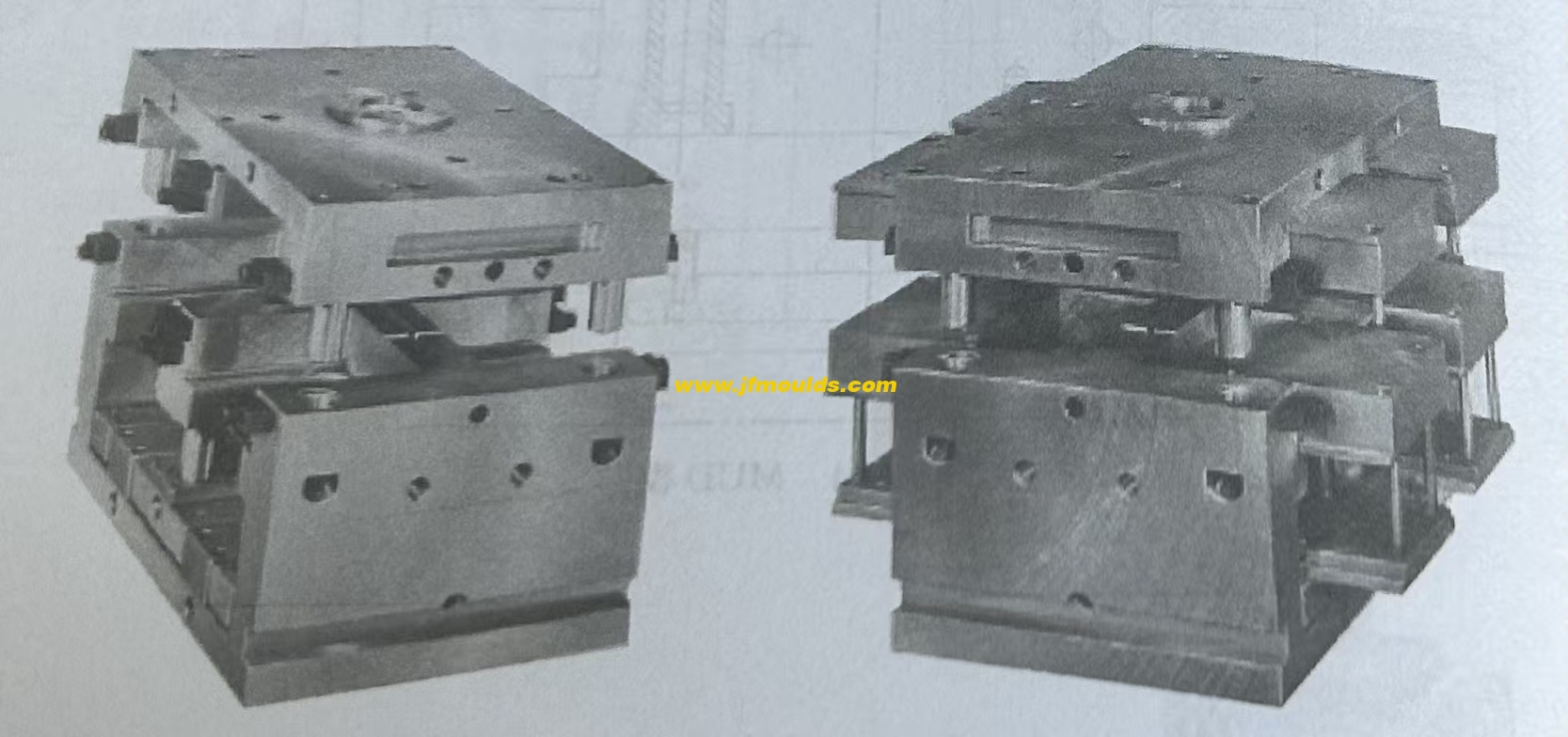

Six: MUD Model

MUD mode is the abbreviation of master unit die, that is, the fast conversion mode frame. Its features are as follows: The mold base is a quick-change plate provided by the customer, and only the inner mold inserts and push rod plates need to be made.

MUD mold precautions: 1. The mold width D is determined by the specification of the quick-change plate. 2. This type of mold is generally small. Attention should be paid to the minimum mold thickness H. If necessary, the length should be increased by C. 3. The entry and exit of the cooling water channels should be designed as close to the top of the mold as possible to avoid colliding with the mold frame.

There are three forms of MUD.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Seven: Selection of mold base specifications and models

To shorten the manufacturing cycle of molds and reduce manufacturing costs, standard mold bases should be given priority for mold bases. The standard formwork models available in the market include commonly used brands such as LKM, FUTABA, MINGLEE and SKJYLUCKY. In the actual design process, it is often determined based on factors such as the customer's requirements, the service life of the mold, the precision grade, the structure of the mold, and the processing degree of the mold base. Standard formwork bases include two-plate formwork bases (also known as large water outlet system formwork bases), standard three-plate formwork bases (also known as fine water outlet system formwork bases), and simplified three-plate formwork bases (also known as simplified fine water outlet system formwork bases). All other mold bases can be evolved from these three types of mold bases.

Related News

How can the surface dirt, water line inclusion and warping deformation of the mold be solved

2025-08-30

How can the surface dirt, water line inclusion and warping deformation of the mo...

In-depth Insights into the Injection Mold Industry: Technological Iteration, Market Landscape, and New Paradigms for Sustainable Development

2025-07-03

In-depth Insights into the Injection Mold Industry: Technological Iteration, Mar...

Explore Huangyan Mould Industry in Deepseek Eyes Together

2025-06-19

1. development process and industrial scale 01 historical evolution Huangyan mol...

Solutions to the deformation at the sprue position of the mold, the flash at the round top pin position (excessive glue), and the baking mark at the glue inlet position

2025-09-02

Solutions to the deformation at the sprue position of the mold, the flash at the...

Limit pins and springs of the mold

2025-10-04

Limit pins and springs of the moldOne: Limit pinThe function of the limit nail i...

Solutions to air streaks and incomplete filling (lack of glue) in molds

2025-08-09

Solutions to air streaks and incomplete filling (lack of glue) in moldsThe air s...