Solutions for the rubber powder and inner side scratches on the sprue of the mold

Solutions for the rubber powder and inner side scratches on the sprue of the mold

The sprue rubber powder of the mold

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 100t, plasticizing capacity: approximately 150g

(2) Mold characteristics

Mold ejection number :1x2, glue entry method: submerged glue entry, ejection method: Ejection by ejection pin, mold temperature :100℃ (constant temperature machine)

(3) Product characteristics

Material: ABS+PC GE1200HF-100, Color: black, Product weight (single piece) : 7.15g, nozzle weight: 2.18g

(4) Analysis of causes of defects

1. The pinholes at the sprue are not smooth, which causes rubber powder to be pulled out during ejection.

2. The iron material of the glue inlet needle is too thin, and it swings when being pushed out.

(5) Countermeasures

1. Save pinholes on the top.

2. Discuss with the mold factory to change the design standard of the nozzle.

Basin mold Manufacturer in China (jfmoulds.com)

The inner side of the mold is scratched

The reason is that the product uses submersible glue. If the operator fails to notice that the water outlet has fallen into the inner position during mold opening, it will cause the mold to be pressed in the next step. This led to the burning of the internal position, causing the inner side of the product to be pulled.

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 100t, plasticizing capacity: approximately 150g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 100℃ (constant temperature machine)

(3) Product characteristics

Material :ABS+PCGN5001RFH, Color: Gray, Product weight (single piece) : 3.83g, spout weight: 16.02g

(4) Analysis of causes of defects

Each product has four hidden gates. It is possible that the operator may not pay attention when opening the mold, causing the gates to fall into the line position, resulting in line position burning and mold pulling.

(5) Countermeasures

Because there were many water outlets and it was inconvenient to take them out, a small slot was made in the mold to connect two adjacent water outlets, achieving the purpose of easy access, saving time and improving production efficiency.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The inner side of the mold is scratched two

Characteristics of injection molding machines

Grade :DEMAG, clamping force: 50, plasticizing capacity: approximately 100g

(2) Mold characteristics

Mold ejection number: 1x2, glue injection method: horn gate, ejection method: Ejection with ejector pins, mold temperature :80℃ (constant temperature machine)

(3) Product characteristics

Material: PMMA IRK-304, Color: Transparent, Product weight (single piece) :8.64g, spout weight: 3.61g

(4) Analysis of causes of defects

It is caused by the fact that the sheet material cannot be positioned during the mold closing process.

(5) Countermeasures

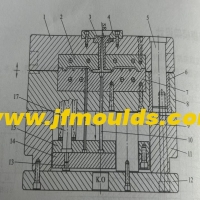

Add an entrant for positioning, as shown in the specific figure.

Related News

Injection molds: The Cornerstone and Future Trend of Precision Manufacturing

2025-07-12

Injection molds: The Cornerstone and Future Trend of Precision ManufacturingBasi...

Injection Mold Base Design (I)

2025-09-26

Injection Mold Base Design (I) The selection of the mold structure is of gr...

Lock module and support column

2025-10-03

Lock module and support columnOne: Lock moduleThe function of the lock module is...

Solutions to the problems of wire clamping, clamping position pull-over deformation and air marks in molds

2025-08-12

Solutions to the problems of wire clamping, clamping position pull-over deformat...

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

2025-07-03

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrou...

From the basics to applications, how does it affect our lives

2025-07-17

From the basics to applications, how does it affect our livesThe basic concepts ...