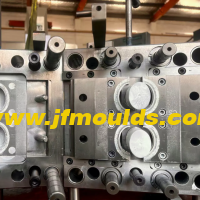

Exhaust the breathable steel of the mold

Exhaust the breathable steel of the mold

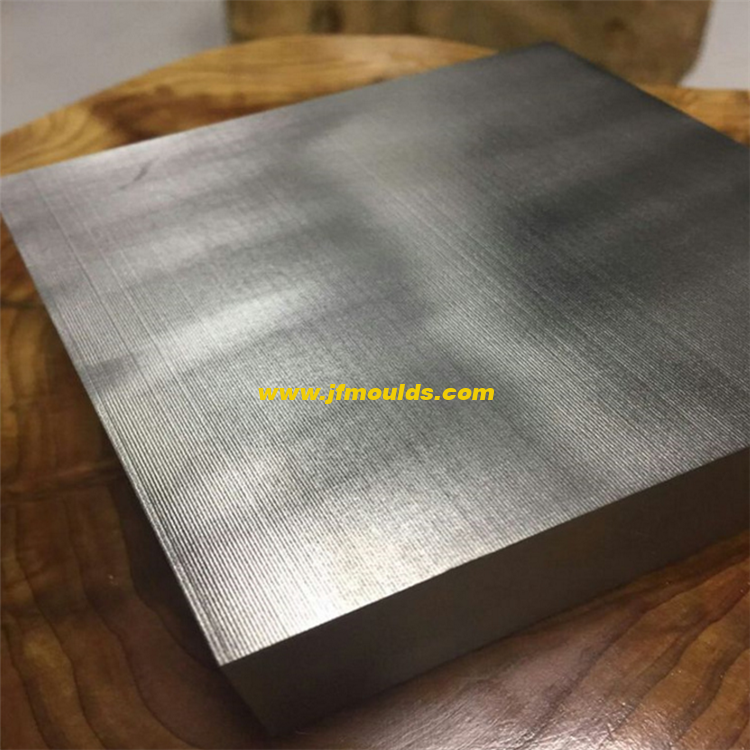

Permeable steel is a sintered alloy. It is a porous material made by sintering spherical granular alloys, with pore diameters ranging from 7 to 10μm. It has relatively poor strength but is loose in texture, allowing gases to pass through. Placing a piece of such alloy at the part that needs to be vented achieves the purpose of venting. However, the diameter D of the bottom vent hole should not be too large to prevent the cavity pressure from squeezing and deforming it. Due to the low thermal conductivity of the breathable steel, it should not be overheated; otherwise, decomposition products are likely to clog the pores.

I. Characteristics of Breathable Steel

1. Low density and high specific strength.

2. Good energy absorption.

3. Good vibration damping effect.

4. Large specific surface area. One quarter of the tissues are through holes.

5. The factory hardness of the breathable steel: Pre-hardened to 350-400HV (35-40HRC).

Two: Characteristics of Breathable steel

Reduce the injection pressure and shorten the molding and holding time.

2. Reduce and eliminate the internal stress of the formed parts to prevent deformation and warping of the products

3. It can solve and alleviate problems such as gate misalignment, uneven wall thickness, and thin-walled plastic parts that are difficult to form

4. Defects such as charring, flow marks, material shortage and part deformation caused by gas generated by high temperature of the forming material and rapid pressure accumulation in the mold cavity can be fully resolved.

5. Enhance the efficiency of molding production and save production costs.

Therefore, by embedding breathable steel at the appropriate positions of the injection mold, the injection molding problems caused by gas can be completely eliminated, making the molding process more perfect.

Three: Detailed Rules for the Use of Breathable Steel

Permeable steel has excellent mechanical properties. When used and used to make injection molds, the same processing methods as general mold steel can be adopted, such as cutting, grinding, and electrical discharge machining. To enable users to fully utilize the advantages of breathable steel, please refer to the following usage guidelines.

After grinding processing or any heavy cutting, micro-pores may get clogged. Soft cutting methods such as wire cutting, electrical pulse cutting and laser cutting should be used for processing (soft cutting refers to a cutting mode that exerts a slight force on the workpiece but does not cause changes in the surface structure). During wire cutting processing, the processing speed should be slightly increased. If it is too slow, electric arcs may be generated in the micro-holes, which is unfavorable for the key wire. When the machining allowance is large, hard cutting can be used, but a allowance of 0.1 to 0.2mm must be left for soft processing to complete.

When restoring the air permeability of the surface of breathable steel, there are various treatment methods

The best approach is to use electrical discharge machining to perform mirror surface processing to clear the material chips blocking the vent holes.

b. Grind by hand with 420-grit sandpaper and then polish with 1200-grit sandpaper.

c. The treatment process is not only carried out on the front side of the breathable steel inner mold part, but also the inner surface of the insert must be treated in the same way to restore its breathability.

d. Exhaust holes shall be provided on the mold frame where the breathable steel inserts are connected. For example, a ventilation hole of about 10mm and an air intake joint for maintenance are set behind the 30mmX30mm PM-35 breathable steel insert.

When breathable steel is used as an insert, it should be kept as close as possible to the mold base at a ratio of 1/10. The thickness of the breathable steel insert should be maintained at 30 to 50mm. The air permeability of breathable steel inserts is affected by their thickness. The thicker the material, the lower the air permeability. However, it must be noted that if the insert is too thin, it may not be able to withstand a large injection pressure. The positions, sizes and quantities on the molds should be reasonably arranged. It is recommended to use it on the moving mold. The air permeability of breathable steel is directly proportional to its surface area; the larger the surface area, the greater the air permeability. The higher the height, the weaker the air permeability. The diameter and thickness should be reasonably selected.

After the air permeability restoration treatment is completed, the oil stains on the surface must be removed and the interior of the material must also be kept clean. The process must follow the sequence of drying → ultrasonic cleaning → drying. It should be noted that the coolant flowing into the material body during processing may clog the micro-pores over a long period of time. Therefore, it should be cleaned promptly after processing is completed.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

4. Other methods for removing oil stains.

a. Remove the breathable steel insert from the mold and heat it to 100-150℃ to allow the oil vapor to vaporize and escape, then rinse the surface with compressed air

b. If the insert is connected to the mold base, the oil stains on the surface can be removed by flushing with compressed air through the exhaust port of the mold base

5. When cutting, grinding and WIRE cutting, the cutting oil used should be of the oil-based type as much as possible. If water-soluble cutting oil must be used, the above-mentioned oil stain removal methods must be adopted immediately after processing to remove the moisture in the steel as soon as possible.

6. When performing EDM wire cutting, it is best to use copper wires with a diameter of 0.25mm or more for processing. However, if EDM copper wire with a diameter of 0.2mm or less must be used, the cutting speed must be increased by 1.5 times compared to usual.

7. Breathable steel cannot be processed by welding (burn-welding). When etching, cleaning treatment before and after processing must be carried out. When it is found that the air permeability of the mold with a breathable steel inner mold part has deteriorated, you can try to treat the oil stains to restore its air permeability.

8. During vacuum heat treatment, dimensional shrinkage or slight deformation may occur. It is necessary to pay attention to reserving processing allowance.

9. When cutting, super-hard alloy tools should be used. Breathable steel inserts are not suitable for thermosetting plastic injection molds, rubber injection molds or molds that require mirror polishing. Do not use SIICONE series mold release agents. The breathable steel protected by rust inhibitor must have the oil stains formed by the rust inhibitor removed before use.

10. The most ideal way to use polishing is to process with ultrasonic waves. 800# to 1000# sandpaper or oilstone can solve the problem of minor clogging of micro-holes, but it is also necessary to pay attention to the cleaning of grinding materials. The air permeability should be checked at any time. It is best to polish while taking in air after assembly is completed. After processing, clean with acetone. If ultrasonic cleaning combined with acetone is used, the effect will be even better. When assembling, do not directly strike with hard objects as this will block the micro-holes. Instead, use a pad made of hard wood or purple copper to strike in. After assembly, apply acetone or kerosene to the surface as the medium, and use the air outlet holes to introduce high-pressure air to check the ventilation effect. The entire surface should uniformly and forcefully bubble. If a decline in air permeability is found, it can be compensated by soft processing methods such as strengthening machines, electrical pulses, and lasers, and then cleaned with acetone. After complete drying, it can be restored. Due to the material's reticular micro-porous structure, it cannot be used as a large-area or integral mold structure; otherwise, it will cause a decrease in the precision of plastic products and a reduction in the mold's lifespan.

When designing breathable steel, the following points should be noted:

① The breathable steel can be directly connected with screws

② Exhaust grooves should be made at the bottom of the insert

If cooling water is to be passed through the breathable steel, the cooling water holes should be electroplated.

The factory hardness of the breathable steel is 35 to 38HRC, but it can be hardened to 55HRC. Special instruments are required to test the hardness.

Related News

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...

How can the frequent breakage of the water inlet needle of the mold, the raised bone position and the excessive glue on the side (flash) be solved

2025-08-22

How can the frequent breakage of the water inlet needle of the mold, the raised ...

Injection molds: Specialized manufacturing, empowering new quality productivity in the industry

2025-07-14

Injection molds: Specialized manufacturing, empowering new quality productivity ...

Design of Exhaust System for Injection Molds (1)

2025-10-14

Design of Exhaust System for Injection Molds (1)I. Reasons for setting up an exh...

From the basics to applications, how does it affect our lives

2025-07-17

From the basics to applications, how does it affect our livesThe basic concepts ...

Solutions to the problems of wire clamping, clamping position pull-over deformation and air marks in molds

2025-08-12

Solutions to the problems of wire clamping, clamping position pull-over deformat...