Plastic parts

Plastic parts

One: Dimensional accuracy of plastic parts

The dimensional accuracy of plastic parts is influenced by multiple factors such as the plastic, the structure of the plastic part, the precision of the mold, and the fluctuation of the shrinkage rate of the plastic part during injection molding production. Designers cannot simply apply the dimensional tolerances of mechanical parts. Many industrialized countries have formulated dimensional tolerances for plastic parts based on the properties of plastics. China also issued GB/T14486-1993 "Dimensional Tolerances of Engineering Plastic Molding Parts" in 1993. In 2008, it was revised again and renamed "Dimensional Tolerances of Plastic Molding Parts".

Two: Selection of Tolerance Grades for Common Parts

As there are many factors that affect the dimensional accuracy of plastic parts, it is very important to correctly and reasonably determine the dimensional tolerance in the design of the parts.

Generally speaking, under the premise of ensuring the usage requirements, the precision should be designed to be as low as possible.

Three: Surface quality of plastic parts

The surface roughness of plastic parts should comply with the regulations. The surface roughness of the general mold cavity should be 1 to 2 grades lower than the requirements of the plastic part.

Four: The draft Angle of the plastic part

To ensure that the plastic part can smoothly detaching from the cavity and core during mold opening, and to prevent the plastic part from sticking to the mold or scratching the surface during demolding, etc., the outer surface of the plastic part facing the mold opening direction should have a reasonable demolding slope. The principles for designing the draft Angle are as follows

To avoid affecting the assembly of plastic parts, the demolding slope is generally made in the direction of material reduction (rubber).

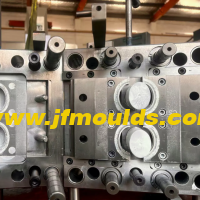

Crate mold Manufacturer in China (jfmoulds.com)

2. When the inner and outer sides of the same wall of the plastic part are respectively formed by a fixed mold cavity and a moving mold core,

For A and B, the draft Angle B of the concave die should be greater than that of the convex die. The purpose is to ensure that the plastic part remains in the moving mold during mold opening. However, when the plastic part is too high, it will cause uneven wall thickness. Therefore, in actual work, a= B is mostly taken. However, when the inner and outer sides of the same wall of the plastic part are formed by the same side of the mold or simultaneously by the lateral core-pulling mechanism, for C, D and E, F, the situation is exactly the opposite. The draft Angle on the inner side should be slightly larger than that on the outer side, because the clamping force of the plastic part on the core is always greater than the adhesion force of the plastic part on the cavity.

3. Different types of plastics have different draft angles. The draft Angle of hard plastics is larger than that of soft plastics. The release slope of plastic with a large shrinkage rate is larger than that of

plastic with a small shrinkage rate. Reinforced plastics should have a slightly larger draft Angle. The inclined film for demolding of self-lubricating plastics can be taken smaller. The draft angles of commonly used plastics are shown in Table 2-7.

4. The shape of the plastic part also has a certain influence on the draft Angle. The higher the height of the plastic part, the deeper the hole. To ensure the fine skin requirements, the draft Angle should be a little smaller. For plastic parts with more complex shapes or more forming holes, a larger draft Angle should be adopted. For large curved plastic parts with thick walls, the draft Angle can be taken as a larger value.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The higher the precision requirement, the smaller the draft Angle required.

6. The draft Angle is not included in the tolerance range.

7. Different surface roughness of the cavity leads to different draft angles.

For transparent plastic parts, the surface of the mold cavity is mirror-polished: the draft Angle for small plastic parts is greater than 1°, and for large plastic parts, it is 3°

The surface of the B plastic part requires etching lines, and the surface of the mold cavity should be sandblasted or corroded: when Ra< 6.3 μ m, the draft Angle should be greater than 3 ". When Ra26.3pum, the draft Angle is 4°.

The surface of the c plastic part is required to leave a fire pattern. The surface of the mold cavity is not polished after electrode processing: when Ra<3.2pm, the draft Angle is 23%. When Ra is 3.2 μ m, the draft Angle is 4°

8. The draft Angle for the characters, symbols, etc. on the plastic part is set at 8° to 12°.

Related News

The elastic rubber of the mold and the fixed-distance parting mechanism

2025-10-05

The elastic rubber of the mold and the fixed-distance parting mechanismOne: Elas...

Exhaust through the vent plug and vent valve of the mold

2025-10-18

Exhaust through the vent plug and vent valve of the moldOne: Exhaust through the...

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...

Surface roughness of plastic parts and selection of injection molding machines

2025-09-18

Surface roughness of plastic parts and selection of injection molding machines1....

In-depth Insights into the Injection Mold Industry: Technological Iteration, Market Landscape, and New Paradigms for Sustainable Development

2025-07-03

In-depth Insights into the Injection Mold Industry: Technological Iteration, Mar...

The coordinated evolution of technological iteration and industrial ecosystem

2025-07-15

The coordinated evolution of technological iteration and industrial ecosystemI. ...