Basin mold

Details

Injection mold manufacturer

As one of the most competitive and leading mold manufacturers in China, Jiefeng Mold has been dedicated to the research, development and production of such molds for over a decade. With advanced technology, rich experience and a strict quality control system, we are always able to provide global customers with high-precision, high-durability and high-quality plastic molds, helping manufacturers create more competitive products in the market.

Basic Information:

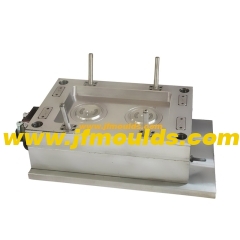

| Mold name | Basin mold |

| Mold material | P20,45# steel,S136,H13.718H,etc. |

| Runner | Hot runner |

| Hot runner brand | YUDO |

| Design software | UG |

| Mold life | 1.000.000 |

| Delivery time | 35-60days |

| Plastic material | PP PC ABS PE PVC ABS+PC PS.etc. |

| Warranty period | one year |

| Mold cavity | Single cavity |

| Gate Type | Pinpoint Gate,Edge Gate,Sub Gate,Film Gate,Valve Gate,Open Gate,eat |

| Mould Surface Treatment | EDM, texture, high gloss polishing |

| Quality System | SGS |

| Origin | Made in China |

| Installation | fixed |

| Cavity | Cavity |

| Specification | Depends on customer's requirements |

| Mold Cooling System | water cooling or Beryllium bronze cooling. etc. |

| Mold Hot Treatment | quencher, nitridation, tempering.etc. |

| Packaging size(mm) | It depends on the customer's demands |

| Gross weight of packaging | Calculate based on customer requirements |

Our Advantages:

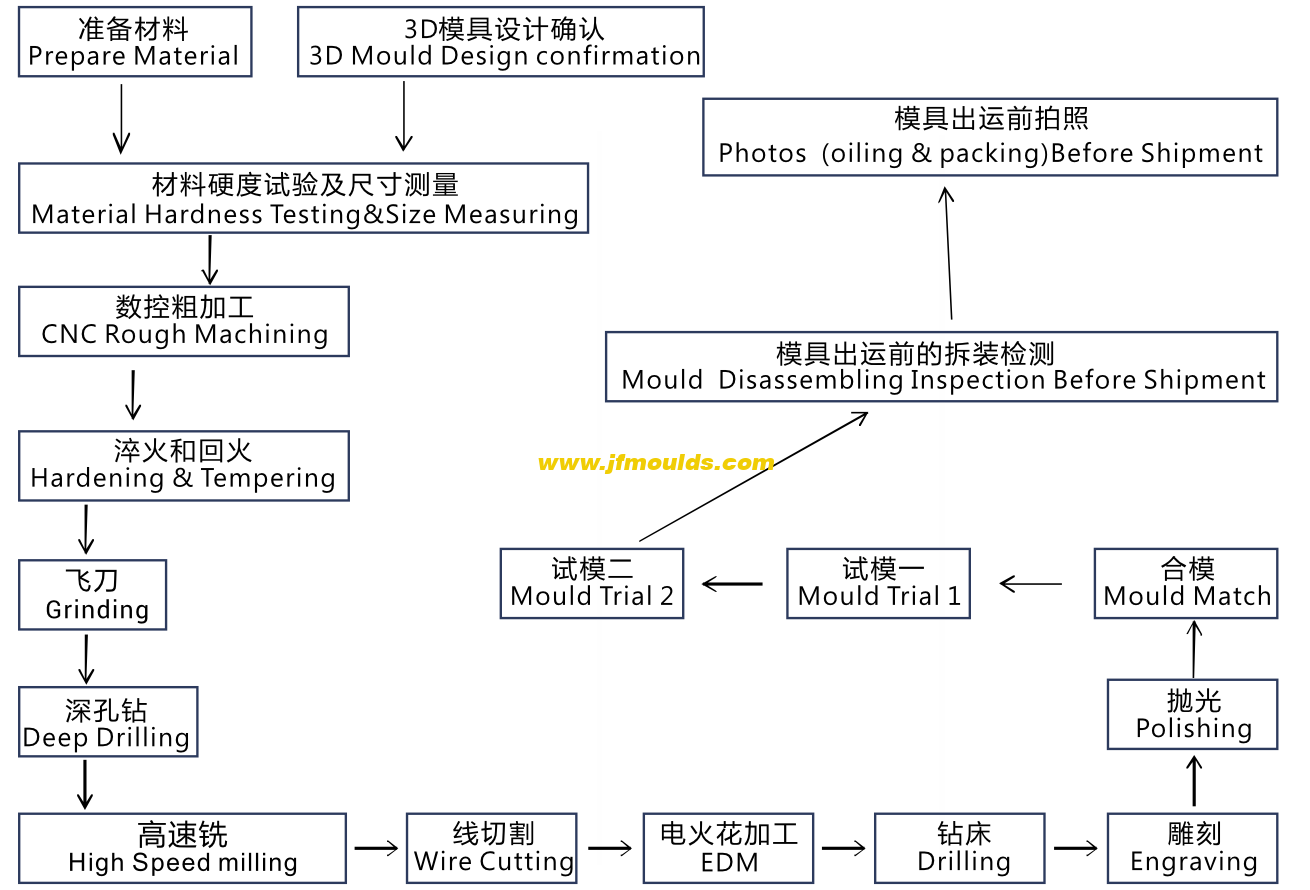

1. Technological and process advantages:

Possessing professional mold design capabilities (such as optimizing structures using CAD/CAM/CAE software), being familiawith the forming characteristics of different materials (such as PP, ABS, PC), capable of solving mold manufacturing problemswith complex structures (such as thin walls, multi-cavities, and precise patterns), ensuring product accuracy and consistency

2.Cost optimization capability:

Through large-scale production, supply chain integration (such as bulk procurement of raw materials). and optimized desion omold life, the cost of each mold and the loss in subsequent injection molding production can be reduced. At the same time, anintegrated "mold + iniection molding" service can be provided to reduce the additional costs of mult-link connection forcustomers.

3. Delivery and Service efficiency

With mature production processes and equipment (such as CNC machining centers and EDM EDM machines). the molddevelopment cycle can be shortened (usually from design to trial mold can be compressed to several weeks). At the same timewe provide after-sales maintenance (such as mold repair and maintenance) and rapid mold modification services to reduce thedowntime of customers' production lines.

4. Quality control capability:

Establishing a ful-process quality inspection standard (from raw material entry, processing process inspection to sampleverification), and some manufacturers obtaining 1S0 and other system certifications can ensure the long-term stable operation ofmolds and reduce the product scrapping rate caused by mold defects

JieFeng Mould will provide customer fow analysis. and use simulation software to verify the basic details of the fiing processdissolution wiring, deformation, and other die designs. These characteristics will define the high quality of the die to ensure theaccuracy of the initial stage of the project and to ensure success at T1

We provide a full range of processing technology, up to five axesThe software is suitable for all 2D,3D, and five-axis programming.The machine is equipped with an automatic tool changer and a laser calibration tool.The high-speed machining center is equipped with an automatic detection function of the workpiece off the machine

Packaging and transportation:

Jiefang Mould, with its strict shipment inspection standards, systematic packaging protection system and rapid response after-sales mechanism, has built a full-chain safety guarantee closed loop from the factory to the customer's production line, ensuring that every set of moulds can be safely and reliably delivered and put into production.

1. Mold shipment: Multi-dimensional inspection builds a solid quality defense line

To ensure the quality of molds from the root, Jiefang has established a multi-stage and multi-level inspection mechanism. From the dimensional accuracy and structural strength of the molds to their surface finish and functional compatibility, all are subject to strict inspection by professional testing equipment and experienced quality inspection teams to ensure that each set of molds meets or even exceeds industry standards and customer requirements.

2. Professional Packaging: Standardized processes create a "safe fortress"

Jiefang adopts a standardized and refined full-process packaging technology to build an impregnable "safety fortress" for molds:

Cleaning and rust removal: Through professional cleaning equipment and rust removal processes, thoroughly remove oil stains, dust and rust on the surface of the mold to ensure its cleanliness.

Anti-rust protection: High-quality anti-rust materials are selected, and multiple anti-rust treatments such as spraying and soaking are adopted to coat the molds with a "protective armor", effectively resisting the risk of rusting during transportation and storage.

Sealed packaging: Use packaging materials with excellent sealing performance to tightly wrap the molds to prevent the invasion of external factors such as air and moisture.

Sturdy packaging: According to the size and weight of the mold, customize a sturdy packaging structure, such as high-strength wooden boxes, metal frames, etc., to ensure that the mold is not damaged by collision or compression during transportation.

3. Full-cycle technical support: One-stop service ensures smooth production

Warranty period: We offer industry-leading warranty period services. During the warranty period, if there are non-human-induced quality issues with the mold, free repair or replacement services can be enjoyed.

Standardized mold frame and maintenance for internal after-sales response: Establish a 7× 24-hour rapid response mechanism. After receiving the customer's after-sales request, the technical team will provide remote guidance or on-site service in the first instance. At the same time, standardized mold bases are provided to facilitate mold maintenance and upgrades, reducing maintenance costs.

Professional assembly guarantees post-warranty technical support: Equipped with a professional assembly team, we can provide on-site assembly and debugging services for molds to customers, ensuring rapid production of molds. Even after the warranty period, we still provide continuous support such as technical consultation and paid maintenance to help customers achieve long-term stable production.

From the rigorous layer upon layer of shipment inspection to the comprehensive packaging protection, and then to the always-on after-sales support, Jiefang Mould, with its professional, meticulous and full-cycle service system, ensures that customers have no worries at every stage of mold delivery and use, thereby fully guaranteeing their production efficiency and economic benefits, and becoming a solid backing for customers' mold procurement and production.