The elastic rubber of the mold and the fixed-distance parting mechanism

The elastic rubber of the mold and the fixed-distance parting mechanism

One: Elastic glue

Elastic rubber is often used in injection molds in the following two situations.

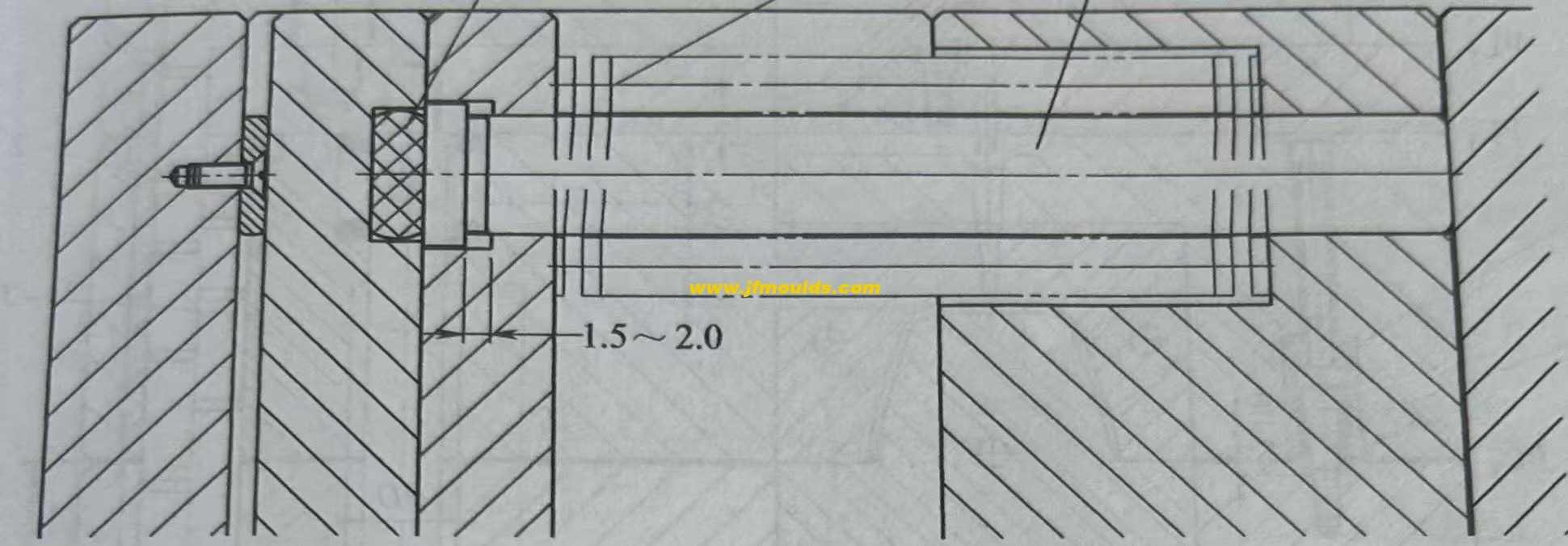

1. Under the reset rod, enable the reset rod to have the function of resetting first. After the mold is opened, the elastic rubber pushes the reset rod out by 1.5 to 2.0mm. When closing the mold, the fixed mold touches the reset rod first. Before the parting surfaces of the moving and fixed molds come into contact, the push rod plate is pushed back to its original position.

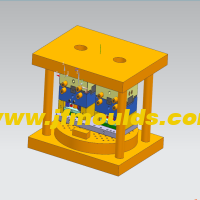

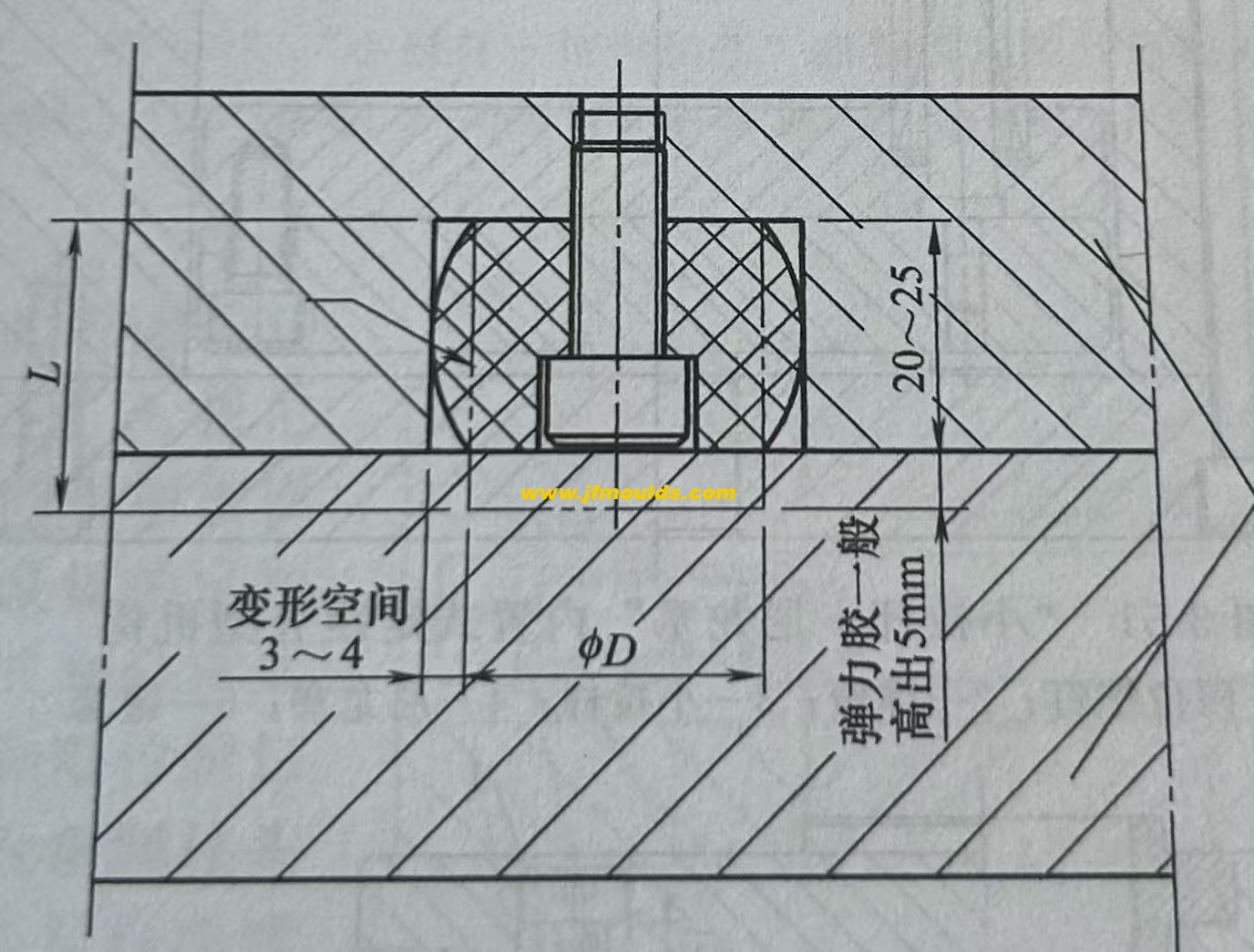

2. Replace the springs between the movable templates. Sometimes in large molds, there is a considerable adhesive force between the templates. When the mold is opened, there will be a large adhesive force. Elastic glue is often installed between the templates to ensure that each template can be opened smoothly during mold opening. In the picture, the elastic rubber is in a compressed state, and its free size is ΦD×L.

Flowerpot injection mold Manufacturer in China (jfmoulds.com)

Two: Fixed-distance typing mechanism

When a mold has two or more parting surfaces, a spacing parting mechanism needs to be set up on the mold to ensure the opening sequence and distance of each parting surface. There are many forms of spacing parting mechanisms. The following discusses them one by one.

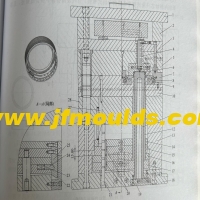

1. Built-in small pull rod fixed-distance parting mechanism

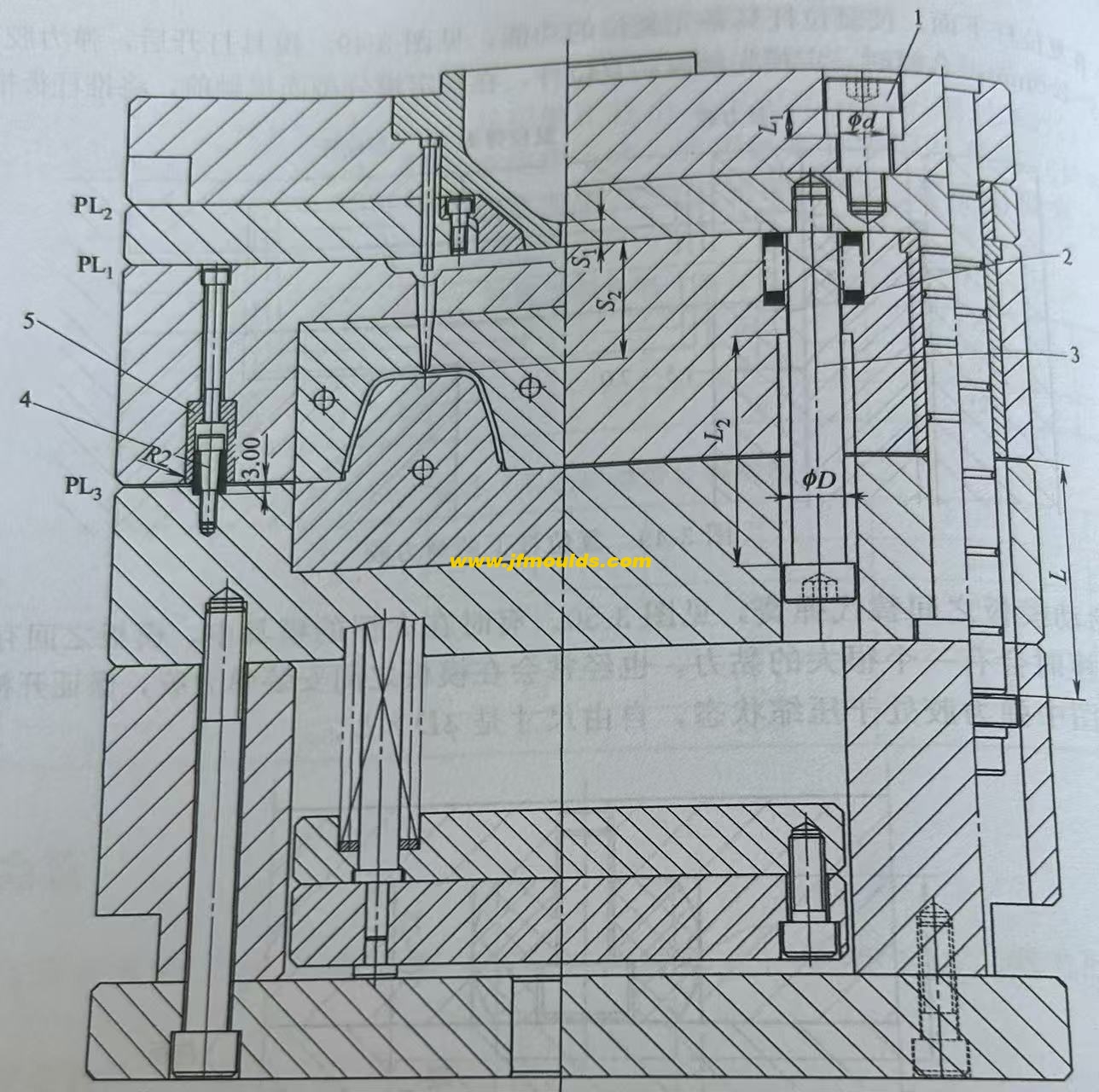

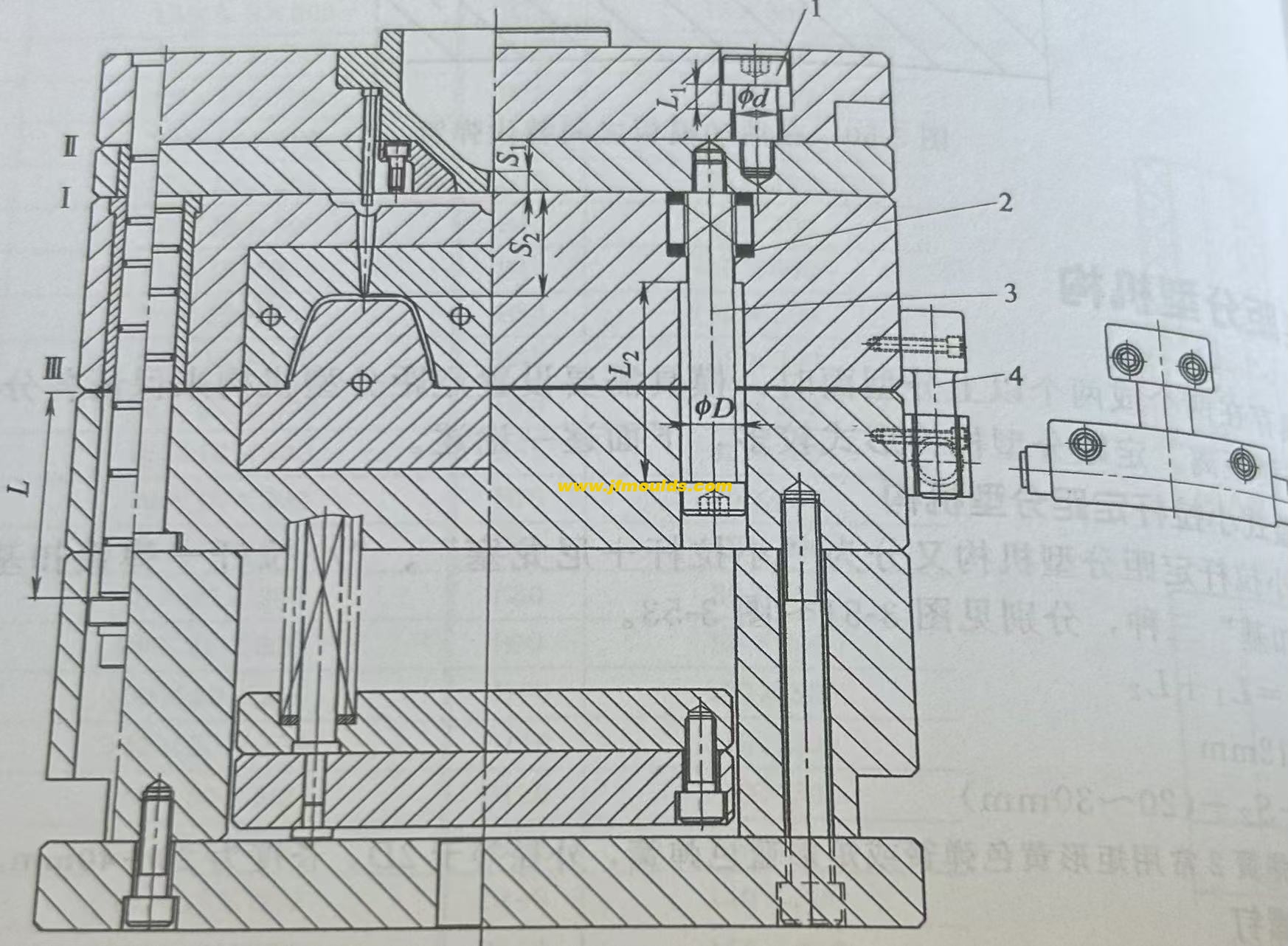

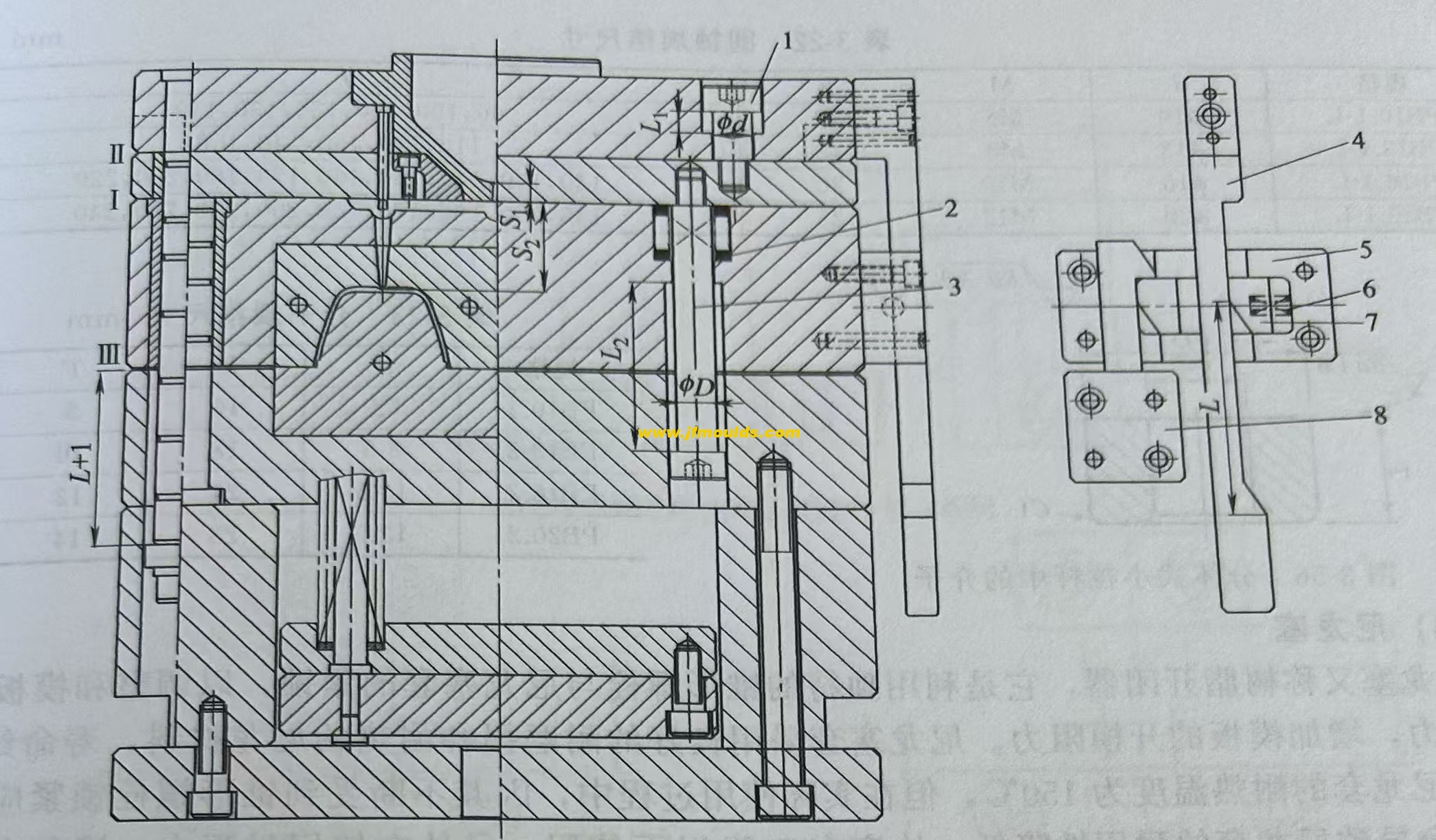

The built-in small pull rod spacing mechanism is further divided into three types: "small pull rod + nylon plug", "small pull rod + spring buckle base" and "small pull rod + pull hook buckle base".

In the figure: L=L1+L2,L1=8-12mm, L2=S1+S2+(20-30mm). Here, spring 2 is commonly a rectangular yellow spring or a rectangular blue spring, with an outer diameter of 2D and a length of 20-40mm.

Limit spring

In three-plate molds, limit screws are used to restrict the mold opening distance between the runner push plate and the panel. In other multi-parting surface molds, they are used to limit the mold opening distance of the movable template. The commonly used limit screws are standard hexagon socket cylindrical head shaft shoulder screws, also known as sanda screws.

(2) Small pull rod

In three-plate molds, small pull rods are typically used to limit the opening distance between the flow channel push plate and the fixed mold A plate. They can also be used for the fixed distance parting of movable templates in other multi-parting surface molds. There are two types of small pull rods: integrated and split. The integrated small pull rod, like the limit screw, uses standard hexagon socket cylindrical head shaft shoulder screws. The split small pull rod is composed of screws, spring washers, spacers and a round shaft.

(3) Nylon stopper

The nylon plug, also known as the resin switch, uses a unique energy bolt to tightly lock with the nylon plug sleeve to adjust the friction between it and the template, increasing the mold opening resistance of the template. The nylon plug sleeve is made of high-quality wear-resistant and heat-resistant nylon material, with a service life of approximately 5 years

Ten thousand times. The heat resistance temperature of the nylon sleeve is 150 ° C. However, during actual use, due to the continuous effect of the locking stress of the conical bolt, the durability of the nylon sleeve will decrease. Therefore, it is advisable to use it below 80 ° C. In addition, during the usage process, do not add oil to the resin, otherwise it will reduce the friction force and decrease the mold opening resistance.

(4) Spring switch

The spring switch is also known as the spring buckle base. Two sets are often used for assembly and are installed on both sides of the mold.

(5) Hook switch

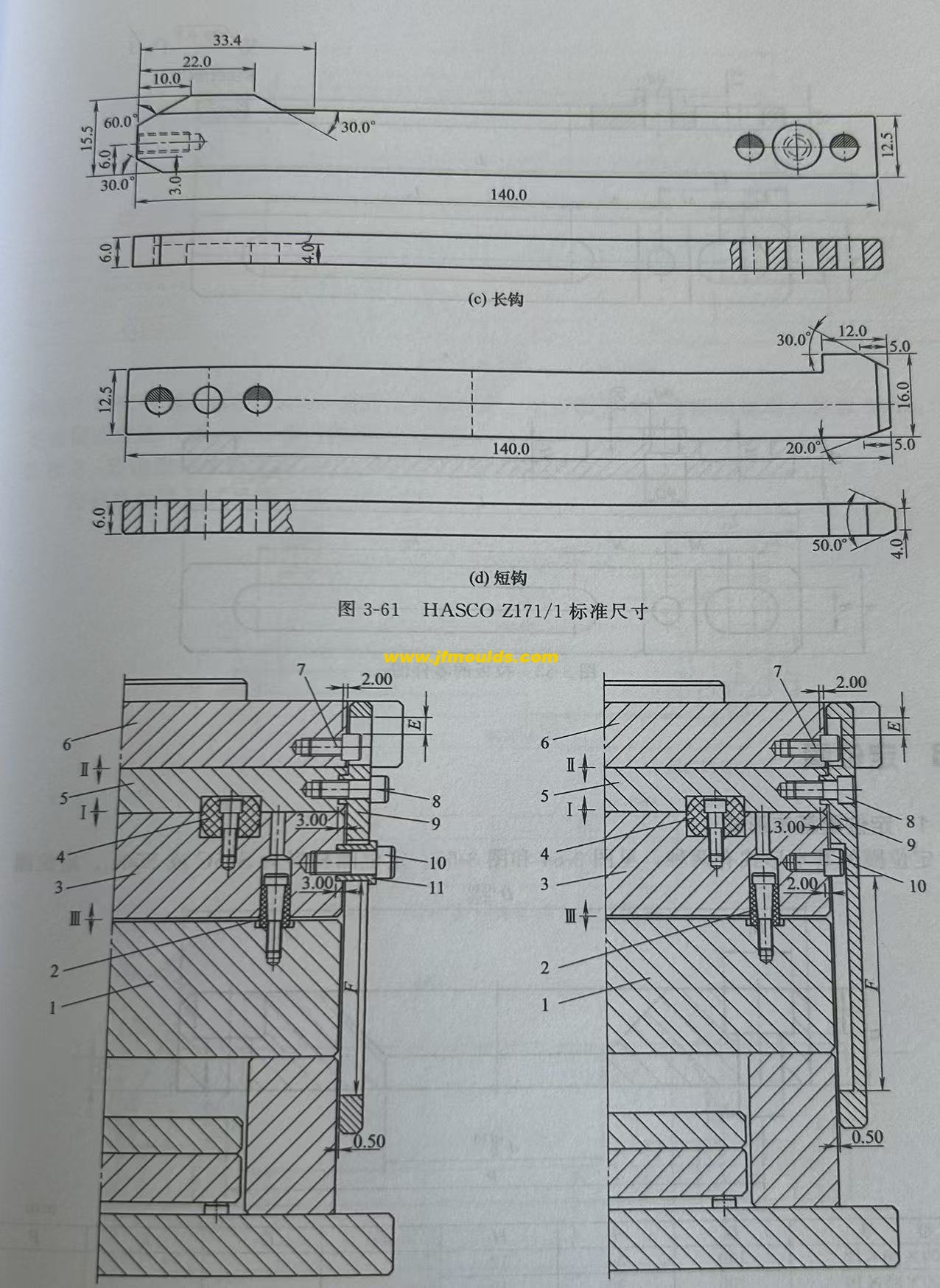

The hook switch, also known as the hook base, mainly comes in three forms. There are two of them, installed on both sides of the mold. Except for the springs, all the hook openers are made of oil steel and need to be nitrided. A standard size of Type B hook switch, and the length of the hook can be determined as needed.

2. External pull plate bottom fixed-distance parting mechanism

The external pull plate fixed-distance parting mechanism uses pull plates to replace the small pull rods and limit screws in the internal fixed-distance parting mechanism. The commonly used quantity is 4, symmetrically arranged. When the mold width is less than 250mm, two can also be used, but they must be arranged diagonally. There are two structures for the pull plate: one is the through-hole structure, and the other is the blind hole structure. The material for the plate pulling is 45 steel or yellow grade steel S50C, and no heat treatment is required. The advantage of this structure is that it is convenient for maintenance, so it is more widely used. The nylon plug or switch that matches the pull plate is the same as the built-in distance setting and parting mechanism.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Mainstream path design

2025-10-21

Mainstream path design From the perspective of reducing pressure and heat l...

Entering the World of Injection Molds: An Analysis of Technology and Industrial Development from Multiple Perspectives

2025-06-28

Garbage can mold Manufacturer in China (jfmoulds.com)intotheWorldofInjectionMold...

Solutions for trapped gas burning, surface wire clamping and insufficient glue in the inner column of the mold

2025-08-11

Solutions for trapped gas burning, surface wire clamping and insufficient glue i...

Explore Huangyan Mould Industry in Deepseek Eyes Together

2025-06-19

1. development process and industrial scale 01 historical evolution Huangyan mol...

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

2025-07-03

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrou...

Thread demolding

2025-11-17

Thread demolding(1) Forced demolding of the thread The mold structure of th...