Calculation of injection mold forming dimensions

Calculation of injection mold forming dimensions

I. Calculation Method for General forming Dimensions

The core and cavity shapes of the mold are mirrored from the plastic part drawing, and the forming dimensions are obtained by adding the demolding slope and the average shrinkage rate to the plastic part dimensions. There are currently two calculation methods for forming dimensions as follows.

1. International Calculation Method

Cavity internal dimensions: DM=[D(1+S)-3/4×△]+δ

2. Cavity depth dimension: HM=[H(1 + S)- 2/3x △]+ δ

3. Core external dimensions: dm=[d(1+S)+3/4×△]-δ

4. Core height dimension: hM-Lh(1+S)+2/3×△]-δ

5. Center distance dimension: CM-[C(1+S)]±δ

6. Center margin dimensions: LM=[L (1+S)-3/4×△]±δ, where D.H,d,h,C,I are the dimensions of the plastic part; dM,hM CM,IL and the corresponding mold size of the plastic part :S shrinkage rate;

△- Plastic part tolerance: Before calculation, the physical dimensions must be converted to unidirectional negative tolerance, the hole dimensions to unidirectional positive tolerance, and the position dimensions to positive and negative bidirectional tolerance:

The tolerance of δ -mold parts, the precision grade is usually taken as IT5 to 1T6

Paint bucket mold Manufacturer in China (jfmoulds.com)

(2) Simplified calculation method

The simplified calculation method is widely used in the Pearl River Delta region.

When the size of the plastic part is free tolerance :DM=D(1+S)

The forming dimensions of the DM mold in the formula; The basic (nominal) dimensions of D-plastic parts. The dimensional tolerance for forming is usually taken as IT6 to 1T8 grade.

When the size of the plastic part is a non-free tolerance, there are the following two calculation methods

The basic dimensions of the forming size are still calculated by the following formula: DM=D(1+S), and the dimensional tolerance of the forming is taken as 1/3 to 1/2 of the dimensional tolerance of the plastic part.

b. The basic dimensions of the forming size are calculated by the following formula: DM ² [(Dmax+Dmin)/2](1+S), where Dmax is the maximum limit size. D min minimum limit size.

The dimensional tolerance of the forming part is still 1/3 to 1/2 of the dimensional tolerance of the plastic part.

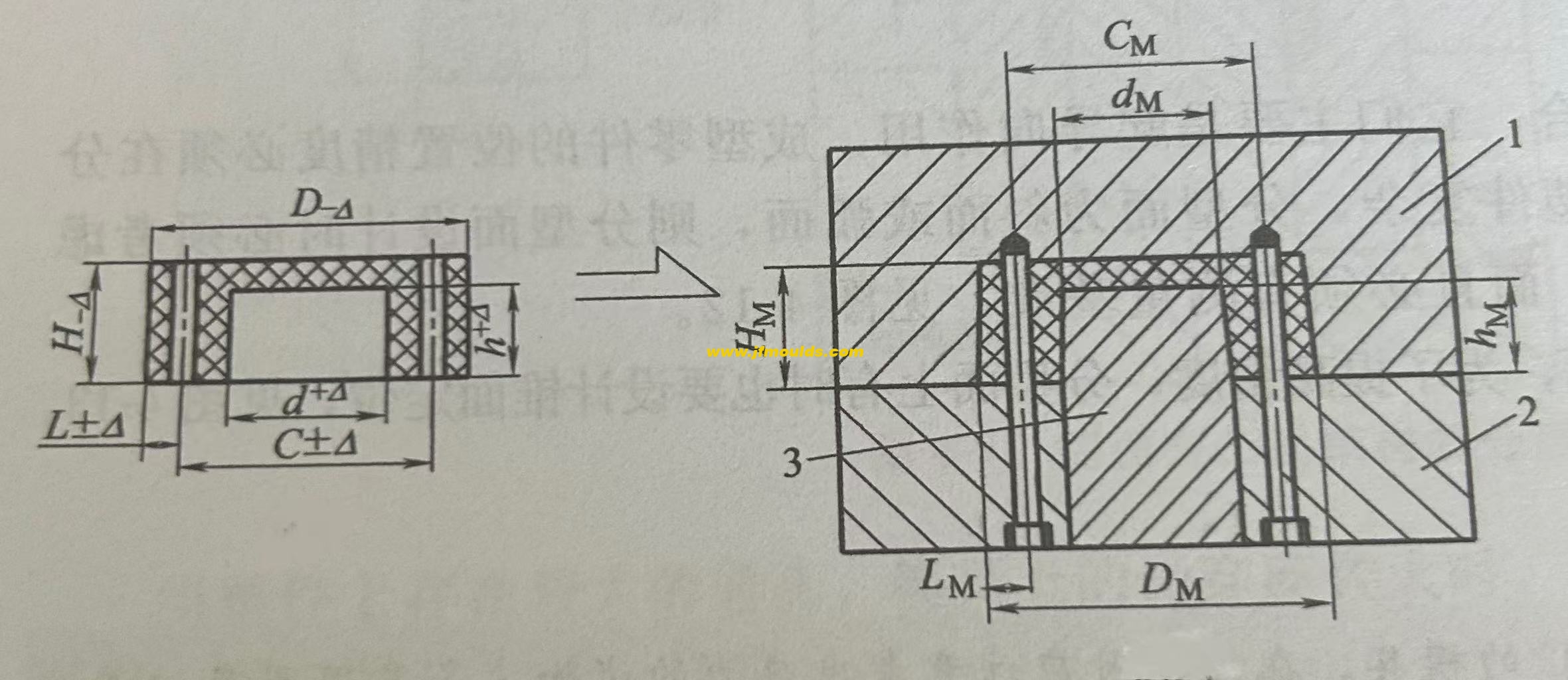

Two: Calculation of the forming dimensions of plastic part molds with metal inserts

When the center of a plastic part is equipped with a metal insert, the calculation of the cavity size is DM=[D+(D-d)S-3/4X△]+δ.

When there are multiple metal inserts, the calculation of the center distance dimension of the holes is CM=[C+(C-nd)s]±δ, where the outer diameter of the metal inserts;

Number of inserts

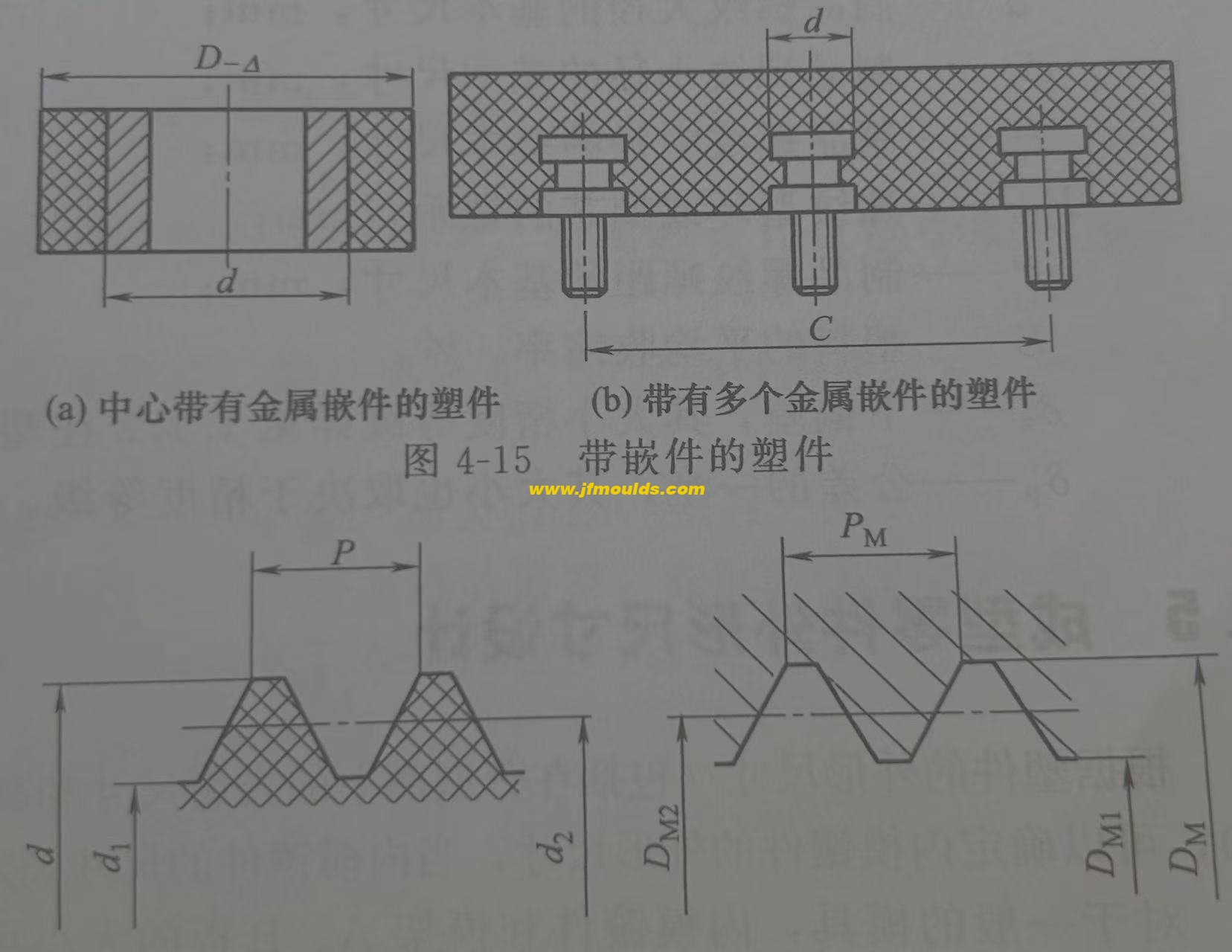

Three: Calculation of pitch dimensions for threaded rings and threaded cores

PM = (P + PS) plus or minus delta P

The large diameter size of the DM threaded ring in the formula, mm;

Diameter size of D M1 threaded ring,mm;

The diameter of the DM2 threaded ring,mm;

The large diameter size of the dM threaded core, mm;

The diameter size of the D-M threaded core, mm;

The centerdiameter size of the d M2 threaded core,mm;

The basic size of the thread diameter of product d,mm;

The basic size of the thread diameter of d1 product,mm;

The basic dimensions of the thread pitch diameter of d2 products,mm;

The pitch of the PM threaded ring or core, mm;

The basic dimensions of the thread pitch of p products, mm;

The average shrinkage rate of s plastic, %.

δz lower deviation.

The δp tolerance is half, and its size also depends on the precision grade.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

The coordinated evolution of technological iteration and industrial ecosystem

2025-07-15

The coordinated evolution of technological iteration and industrial ecosystemI. ...

Huangyan: Building a

2025-06-22

Huangyan District of Taizhou City is known as the "hometown of moulds in China"....

Plastic properties and molding conditions

2025-09-13

Plastic properties and molding conditions Different plastics have different pr...

Solutions to surface flow patterns, deformation and ejection deformation on both sides of the mold

2025-09-04

Solutions to surface flow patterns, deformation and ejection deformation on both...

Limit pins and springs of the mold

2025-10-04

Limit pins and springs of the moldOne: Limit pinThe function of the limit nail i...

The dimensional tolerance of injection mold fit and the surface roughness of mold parts

2025-09-12

The dimensional tolerance of injection mold fit and the surface roughness of mol...