Entering the World of Injection Molds: An Analysis of Technology and Industrial Development from Multiple Perspectives

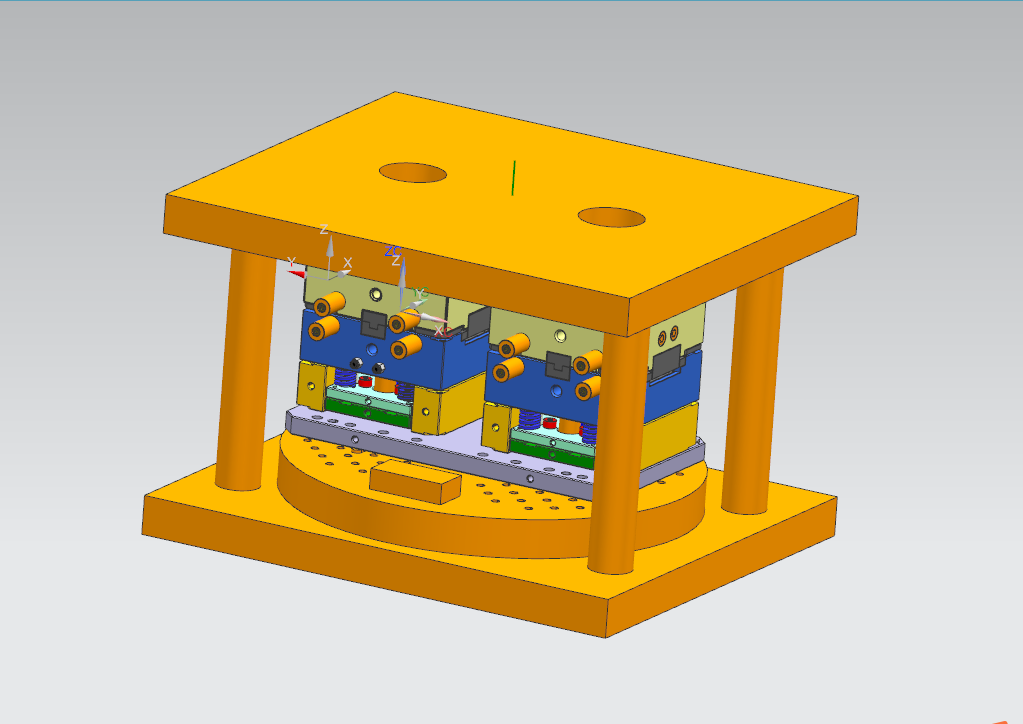

| SystemName | Components | FunctionalDescription |

| gatingsystem | Mainflowchannel,diverterchannel,gate,coldmaterialcavity | Plasticintothemoldcavitychannel,gatedesignkey,toavoidweldmarks,lackofmaterialandotherdefects |

| Moldedparts | Core,cavity,insert | Decideplasticproductsshapeandinternalstructure,precisionelectronicproductsshellinjectionmoldrequirementshighprecision |

Coolingsystem | Cooling system | Controlling the mold temperature affects the molding quality and production efficiency. Conformal cooling technology enhances the cooling efficiency |

| Exhaust system | Exhaust groove, vacuum-assisted exhaust | Expel the air in the cavity to prevent trapped air and charring, ensuring the molding quality of plastic products |

| Demolding mechanism | Push rod, push tube, push plate, lateral core-pulling mechanism, rotary demolding device | Push the cooled and solidified plastic products out of the mold to ensure smooth demolding of the products without deformation |

| Guidance system | Guide pins and guide sleeves | During the opening and closing process of the mold, precise alignment is achieved to prevent the misalignment and damage of mold parts, thereby enhancing the service life and forming accuracy of the mold |

| Support system | Support plates, spacers, support columns | Bear the weight of the mold and the injection pressure. The design should be based on the size of the clamping force to ensure the |

| Mold type | Production characteristics | Applicable products |

| Applicable products | One product is produced by injection molding at a time | Small-batch, large-sized or complex-shaped plastic products, such as large automotive bumpers |

| Multi-cavity mold | Multiple identical products can be produced in one injection molding | Mass production of small plastic products, such as mobile phone keys, electronic component casings, etc |

2.

| Mold type | Flow channel state | Characteristics | Cost | Applicable products |

Cold runner mold | Cooling and solidification | Waste materials need to be processed subsequently | Relatively low | Large injection molded parts, multi-type injection molded parts, products with special or valuable materials, and products that need to be mass-produced |

| Hot runner mold | Constant-temperature melting | Save raw materials and improve product quality and production efficiency | Relatively high | High-end products such as optical lenses and medical plastic products |

3.Moldstructure:

TableofPlasticProductMoldTypes

Mold type | Characteristics | Characteristics |

| Characteristics | Simple structure, low cost and high efficiency | Clothes hangers, trash cans, nuts, gaskets, remote control casings, wooden blocks, etc |

Three-plate mold | The gate is flexible, the appearance is optimized, and the degree of automation is high | Mobile phone cases, camera lens caps, transparent spectacle lenses, plastic cups for monitor casings, etc |

Lateral core-pulling die | It is suitable for the production of plastic products with lateral structures | Plastic three-way pipe fittings |

| Rotating mold | It is used for the production of plastic products with a rotary shape | Plastic buckets, toy balls, etc |

Indifferentindustries,injectionmoldsalsohaveuniqueapplicationrequirements.Themedicalfieldhasextremelyhighrequirementsforthecleanlinessandprecisionofmolds.MoldsusedfortheproductionofbiodegradablematerialproductsneedtomeetGMPcertificationstandards.Theautomotiveindustryhaspromotedthedevelopmentofcontinuousfiber-reinforcedplasticmoldstoachievelightweighting.Withthedevelopmentof5Gcommunicationtechnology,thedemandforproductsmadeoflowdielectricconstantmaterialshasincreased,promptingmoldstoadoptadvancedstructuressuchasflashfreedesignandultrasonicwelding.

Related News

In-depth Analysis of Injection Molds: A Full-Process Exploration from Design to Application

2025-07-10

In-depth Analysis of Injection Molds: A Full-Process Exploration from Design to ...

Injection molds: From millimeter-level precision to the invisible engine of industrial transformation

2025-07-07

Injection molds: From millimeter-level precision to the invisible engine of indu...

Mold drawing design standards

2025-09-09

Mold drawing design standards1. Add the shrinkage dimensions to the plastic part...

Exhaust the parting surface of the mold

2025-10-15

Exhaust the parting surface of the moldThe exhaust grooves on the parting surfac...

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

Injection molds: The Cornerstone and Future Trend of Precision Manufacturing

2025-07-12

Injection molds: The Cornerstone and Future Trend of Precision ManufacturingBasi...