Mainstream path design

Mainstream path design

From the perspective of reducing pressure and heat loss, the conical shape is the most superior mainstream duct shape. The basic dimensions of the main channel usually depend on the following two aspects

The type of plastic used, the quality of the formed plastic part and the size of the wall thickness. Generally speaking, for plastics with poor fluidity, the size of the main channel should be selected to be appropriately larger, while for plastics with good fluidity, the size of the main channel should be selected to be appropriately smaller.

2. The relationship between the geometric parameters of the injection molding machine nozzle and the dimensions of the main runner. To prevent material overflow due to the gap between the nozzle and the gate sleeve, the spherical radius of the gate sleeve should be 2 to 5mm larger than that of the nozzle. The small end size of the runner should be slightly larger than the nozzle hole size to facilitate the alignment of the nozzle and the bushing. The runner should have a smooth surface, and a cold material cavity should be set at the end to prevent cold material from flowing into the cavity and affecting the quality of the plastic part. In injection molds, the runner is all inside the gate sleeve. Gate sleeves can be classified into two types: two-plate mold gate sleeves and three-plate mold gate sleeves. According to the different mold structures, they can be divided into: two-plate mold runner and three-plate mold runner.

One: Mainstream path design

The main runner of the second board mold

The main runner of the two-plate mold can be further classified into vertical main runners and inclined main runners

(1) Vertical main channel

1. d is the minimum diameter of the main runner, that is, the diameter at the contact point between the main runner and the nozzle of the injection molding machine barrel. The minimum value of d is 3.50mm. The nozzle diameter of the injection molding machine is 0.50 to 1.00mm

2.L is the length of the main flow channel. It is determined during the design based on the specific structure of the mold. The shorter the L, the better. When designing, try to make the L 75mm. If L is too long, the gate sleeve can be embedded into the A plate of the fixed mold, but the gate sleeve should not directly press against the fixed mold insert, otherwise the fixed mold insert is prone to loosening under the push of the injection molding machine barrel.

3. The taper of the main flow channel a. a is generally between 2° and 4°. For plastics with high viscosity, a can be taken as 3° to 6°. Due to the limitations of the taper reamer, standard taper values should be selected as much as possible, or standard gate sleeves should be used.

4. Size D is 10% to 20% larger than D'.

5. The positioning ring must be H=10mm higher than the panel. When the assembly method shown in Figure 7-2(a) is adopted, it should be 50mm and D3 80mm.

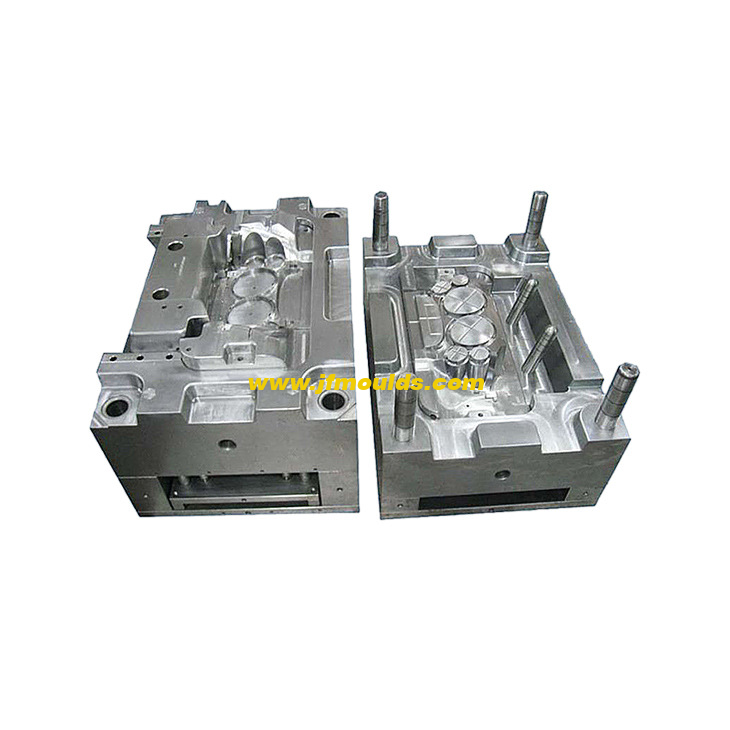

Speaker mold Manufacturer in China (jfmoulds.com)

Inclined main channel

The position of the main runner often deviates from the center of the mold, and sometimes the deviation is quite large, causing many problems when the mold is in use.

When pushing out plastic parts, as the center of gravity of the thrust is not at the center of the mold, the push rod plate and the push rod fixing plate will be subjected to torque during the pushing process, which can easily cause unstable movements of the push rod, the inclined top, the push block and the lever, etc. Over time, these pushed parts are prone to deformation, and sometimes even small pushed parts may break, damaging the mold.

2. As the main runner is not at the center of the mold, the clamping force of the injection molding machine and the expansion force of the melt do not coincide, which can easily lead to excessive expansion force on one side and cause material overflow. To solve these problems, fine sprue three-plate molds can be adopted, but this will increase the manufacturing cost and maintenance and repair cost of the molds. The use of inclined main runner not only solves the above problems and improves its deficiencies, but also saves the manufacturing cost and maintenance cost of the mold. The inclination Angle of the inclined main runner is mainly related to the performance of the plastic. For plastics such as PE, PP, and PA, the maximum inclination Angle B can reach 30° for PS, SAN, ABS, PC, POM, and PMMA. For plastics such as PMMA, the maximum inclination Angle β can reach 20°. Among the design parameters of the inclined main runner, pd is slightly larger than d in the vertical main runner The minimum should be 4.00mm. Other parameters are the same as those of the vertical mainstream. The structure of the inclined mainstream can be further extended into two types: the double-inclined mainstream and the arc-shaped inclined mainstream.

The design of the double-inclined main channel. The design parameters of the double-inclined main channel are the same as those of the single-inclined main channel. It must be noted that in the double-inclined runner, a sharp edge should be maintained at the intersection of the two runner channels to ensure that the two runner channels can be cut during mold opening

And it is easy to mold out.

The function of the double-inclined runner gating system is equivalent to that of the point gate injection system, that is, it replaces the three-plate mold with a two-plate mold, greatly simplifying the mold structure.

Design of the arc-shaped inclined main channel. The radius of the arc in the arc-shaped inclined main channel should not be too small, generally above 60mm. The small end diameter of the arc-shaped inclined main channel is preferably 4.00mm, and the large end diameter is 6.00mm. The main runner is designed on the combined insert (gate sleeve) and fastened as a whole with screws.

The arc-shaped inclined main runner is generally suitable for plastics such as PE, PP, EVA, PVC, and ABS, but not for brittle plastics like PS.

Two: Design of the main runner for the three-board mold

The main channel of the three-board mold is shown in Figure 7-6. Compared with the main channel of the two-board mold, its length I is smaller, usually not exceeding 50mm, while D and a are larger.

The design of injection mold gate sleeves usually includes two major categories: two-plate mold gate sleeves and three-plate mold gate sleeves. The material of the gate sleeve is 45 steel or S50C steel: SR position (spherical surface) quenching heat treatment, with a hardness of 40-45HRC

(1) Two-plate mold gate sleeve

The plate mold gate sleeve is also known as the large sprue gate sleeve. When designing, the following contents should be taken into consideration

1.R must match the spherical radius R' of the injection molding machine nozzle and ensure that: R=R +(1 to 2mm)

2. Inner hole d and taper. It needs to be processed to match the nozzle diameter a 'of the injection molding machine, and ensure that d=d' +(0.5-1mm)

3. The gate sleeve must be tightly pressed to prevent it from receding

4. When the gate sleeve needs to be prevented from rotating.

5. Before the first mold test, the gate sleeve must be hardened to over 40HRC. Two types of gate sleeves have evolved from the standard two-plate mold gate sleeve. Among them, the simplified single support gate sleeve is often used for small and medium-sized simple molds, while the one-piece double support gate sleeve is often used for molds with longer runner channels and larger die thickness dimensions. This type of gate sleeve integrates the positioning ring and the gate sleeve into one. The mold no longer requires a separate positioning ring. Its large end part can serve as a positioning function, so the size of its large end is the same as that of the positioning ring.

(2) Three-plate mold gate sleeve

The three-plate mold gate sleeve, also known as the fine sprue gate sleeve, is a standard type of gate sleeve that is integrated with the positioning ring. Due to the influence of the mold structure, the runner channels of the three-plate mold are all relatively long. Therefore, the length of the main runner channels inside the gate sleeve should be shortened as much as possible.

There are two common types of simplified three-plate mold gate sleeves. Among them, the front-mounted type divides the standard type into two parts and turns its large end into a positioning ring. When assembling, the gate sleeve is directly pressed by the positioning ring. The reverse installation type also removes the large end of the standard gate sleeve that serves as the positioning function, but during assembly, it is fastened to the bottom of the panel through screws.

Related News

The lateral core-pulling mechanism of

2025-10-19

The lateral core-pulling mechanism of "slider inclined guide column"I. Classific...

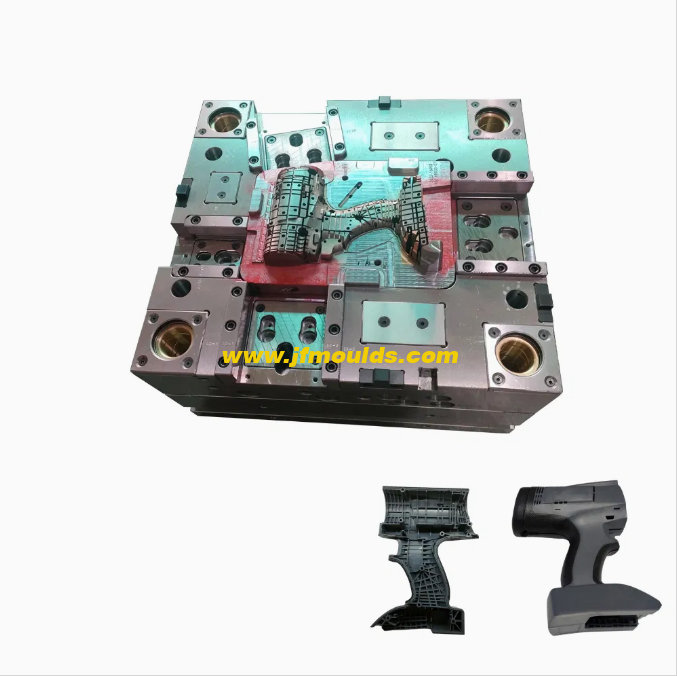

Entering the World of Injection Molds: An Analysis of Technology and Industrial Development from Multiple Perspectives

2025-06-28

Garbage can mold Manufacturer in China (jfmoulds.com)intotheWorldofInjectionMold...

Solutions for air streaks, charring, wire jamming, height elevation or trapped air in molds

2025-08-14

Solutions for air streaks, charring, wire jamming, height elevation or trapped a...

Solution for mold fracture and air wrinkle treatment

2025-08-08

Solution for mold fracture and air wrinkle treatmentFracture of the moldPhenomen...

Exhaust through the vent plug and vent valve of the mold

2025-10-18

Exhaust through the vent plug and vent valve of the moldOne: Exhaust through the...

How can the surface dirt, water line inclusion and warping deformation of the mold be solved

2025-08-30

How can the surface dirt, water line inclusion and warping deformation of the mo...