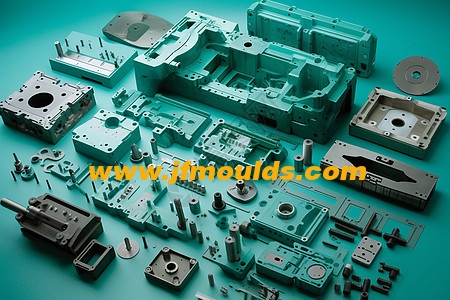

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

I. Technological Depth: From single-point breakthroughs to systematic Innovation

Automobile radiator crossbeam accessories Manufacturer in China (jfmoulds.com)

(1) Smart Molds: Initiating the Era of "Self-evolution"

In 2024, the penetration rate of smart molds will rise to 27%, and its core has shifted from "data collection" to breakthroughs in the "cognitive decision-making" layer. The MEMS sensor built into the mold (with a size reduced to 3mm×3mm) can capture the subtle changes of pressure wave peak difference < 0.05MPa and temperature gradient < 0.2℃ during the injection molding process. Combined with the lightweight algorithm of TensorFlow Lite, it realizes:

Defect prediction

Two cycles before short shots and flash occurred, warnings were issued, reducing the defect rate of a certain automotive interior parts mold from 4.2% to 0.3%.

Process self-adaptation

When the PP melt index fluctuates by ±0.6g/10min, the holding pressure (accuracy ±0.1MPa) and the cooling water flow rate (accuracy ±0.5L/min) are automatically adjusted, and the process stability is improved by 45%.

Digital Twin of Lifespan

Based on the 3D thermodynamic coupling model of mold wear, the prediction error of the remaining life of the mold cavity is less than 5%, and the maintenance cost of a certain household appliance mold is reduced by 32%.

(2) Material Revolution: Exponential Expansion of performance Boundaries

Innovation of matrix materials

The carbide particle size of the fourth-generation powder high-speed steel (such as the ASP-80 nanometer modified version) was refined to 0.8μm. In the injection molding of PA6 + 40%GF, the mold life exceeded 1 million mold cycles, which was 25% higher than that of the third-generation steel.

The magnesium-based composite material (Mg-10% Al₂O₃) has a density of only 1.8g/cm³ and a thermal conductivity of 160W/m·K. In the 5G base station antenna cover mold, it achieves a 40% weight reduction and a 30% shortening of the cooling cycle.

Breakthrough in Surface Engineering

The diamond-like carbon coating (DLC) reduces the surface hardness of the mold to 8000HV through plasma enhanced chemical vapor deposition (PECVD). In PPS high-temperature plastic injection molding, the demolding force is reduced by 75%, solving the industry pain point of "mold sticking and scrapping".

The graphene composite coating (with a thickness of less than 5μm) has an 8-fold increase in wear resistance and a corrosion resistance three times that of stainless steel, making it a standard configuration for plastic parts molds in Marine equipment.

Ii. Market Games: The "Power Shift" in the Global Landscape

(1) The "Waxing and Waning" of Global Industrial Belts

China's injection mold output value accounts for 45% of the global total. The industrial clusters in Taizhou and Dongguan have achieved a leapfrog development by virtue of "technical thickness + cost flexibility + response speed".

In 2023, the export value of auto molds from Taizhou increased by 25% year-on-year, breaking through the monopoly of Germany and Japan in areas such as car hoods (dimensions 1800mm×1200mm, tolerance ±0.05mm) and seat frames (complex curved surfaces + insert injection molding).

Dongguan 3C molds have achieved a tolerance of 0.02mm and 95% automated processing in the molds of Huawei Mate series and Apple Watch Ultra, with a yield rate exceeding 98%.

The traditional mold power is in a "transformation predicament" : The heavy asset model of Germany's Industry 4.0 has led to a 40% increase in the cost of small and medium-sized orders, and its market share has been eroded by 18% by China and Vietnam. The shortage of mold technicians in Japan has expanded to 25,000, forcing it to outsource 35% of its mold production capacity to Southeast Asia, and the risk of technology spillover has intensified.

(2) "Precise Stratification" of Regional Demands

North American market

The expansion of Tesla's Texas Gigafactory and Boston Scientific Medical production lines has given rise to the demand for "mold + mass production collaboration", and they are willing to pay a 35% premium for 48-hour rapid mold repair and full life-cycle mold management.

European market

The REACH regulation has added 22 restricted substances. Molds for biodegradable materials (such as PBS and PHA) must meet the dual indicators of "no residue + microbial tolerance". It promotes joint research and development by "mold enterprises + material manufacturers". DSM of the Netherlands and China Haitian have jointly established a "biodegradable material mold Laboratory".

Southeast Asian market

Samsung's display module factory in Vietnam and Xiaomi's mobile phone factory in Indonesia have started production, leading to a sudden surge in demand for "standardized mold bases + 96-hour delivery". Chinese mold enterprises have set up bonded warehouses in Thailand to achieve "zero inventory and immediate delivery" of molds. In 2023, the export volume to ASEAN increased by 42%.

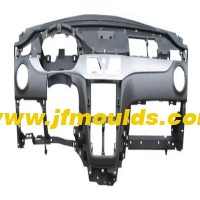

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Iii. Ecological Evolution: The "Synergistic Leap" of Industrial Chains

(1) The explosive development of the "Mold +" ecosystem

Mold + Intelligent Manufacturing

Haitian's "Moyun" system has connected over 500 processing devices. Through digital twins, it enables full-process visualization of mold design, manufacturing, and operation and maintenance, reducing the delivery cycle by 40%. Yinbaoshan has newly developed a "Mold Metaverse" platform, where customers can experience the mold trial process in VR, and the order conversion rate has increased by 28%.

Mold + Circular Economy

The scale of the mold remanufacturing industry has exceeded 6 billion yuan. Xometry has launched a "mold carbon footprint traceability" service, reducing the carbon emissions of repaired molds by 65% compared to new molds. Dongguan Jingsheng has established a mold recycling industrial park, capable of processing 20,000 tons of used molds annually, with a reuse value exceeding 300 million yuan.

Mold + Green Manufacturing

The penetration rate of dry cutting in mold enterprises in the Yangtze River Delta has reached 70%. Combined with an oil mist recovery system, a single factory can reduce carbon emissions by 2 tons annually. The application proportion of bio-based mold materials (such as bamboo fiber reinforced PLA) in children's toy molds reaches 15%, and the carbon emissions throughout their life cycle are reduced by 70%.

(2) The "Dimensional Upgrade Campaign" of Chinese Enterprises

Technical breakthroughs

The 0.5mm wall thickness 5G base station filter mold developed by Huawei's supplier adopts the "gas-assisted injection molding + in-mold electroplating" technology, and the yield rate has increased from 55% to 95%.

Byd's 3M-level battery tray integrated mold, through a composite process of "molding + injection molding + carbon fiber reinforcement", reduces weight by 30% and increases production efficiency by 35%.

Brand Breakthrough

Haitian and Yizhimi led the formulation of 12 international mold standards. The "Detection Method for Surface Roughness Ra0.01μm in China" and the "Industry Specification for Temperature Fluctuation of Hot Runner ±1℃" were included in the ISO standards.

Changying Precision has achieved a 0.01mm tolerance and a lifespan of 700,000 mold cycles for Apple's AirPods molds, with a brand premium of 50%, breaking the monopoly of American and Japanese enterprises in precision molds for consumer electronics.

Supply chain autonomy

The "ultra-pure die steel" process of Baosteel Special Steel makes the impurity content of DC53 steel less than 0.005%, and its performance surpasses that of Japan's Daido Steel. The replacement rate of mobile phone middle frame molds exceeds 80%.

Harbin Institute of Technology Intelligent and Huazhong University of Science and Technology jointly established the "Mold Intelligent Equipment Laboratory", breaking through the "bottleneck" technology of five-axis linkage machine tools, and achieving a mold processing accuracy of ±0.003mm.

Iv. Future Vision: Dual-Driven by Technology and Market in 2025

1."Mold as a Service (MaaS) 2.0" : Mold enterprises have upgraded from "capacity leasing" to "technology + data subscription", such as providing "mold AI algorithm packages" and "process optimization cloud services", and have been the first to be implemented in the medical and automotive core component fields.

2. Cross-domain technology integration: Aerospace "structural topology optimization" and biomedical "cell-level bionic design" deeply empower molds. The automotive bumper mold adopts a honeycomb bionic structure, reducing weight by 40% while enhancing impact resistance by 30%.

3. AI Full-chain penetration: Generative AI automatically generates 3D structures for molds (increasing design efficiency by 60%), the AI production scheduling system enables equipment utilization rates to exceed 90%, and predictive maintenance reduces mold sudden failures by 80%.

4. Regional ecological rise: The mold matching rate in Chengdu-Chongqing (an automotive industrial cluster) and Nantong (a manufacturing hub in the northern wing of the Yangtze River Delta) exceeds 85%, forming a closed loop of "R&D - manufacturing - testing", reducing the supply chain response time by 25%.

As the "crown jewel" of the manufacturing industry, the development of injection molds has become a core symbol of a country's technological strength and industrial resilience. Under the triple impetus of technological breakthrough (intelligence + materials), market reconstruction (global transfer + regional in-depth development), and ecological upgrading (collaboration + autonomy), China's mold industry is rewriting global industrial rules with "systematic competitiveness", and the leap from a "mold giant" to a "mold power" has entered a critical sprint period. Every opening and closing of the mold will become a footnote to the upgrading of China's manufacturing industry.

Related News

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

2025-07-03

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrou...

Injection Mold Base Design (I)

2025-09-26

Injection Mold Base Design (I) The selection of the mold structure is of gr...

How can the top white and surface elevation of the mold be solved

2025-08-26

How can the top white and surface elevation of the mold be solvedThe top white o...

From the basics to applications, how does it affect our lives

2025-07-17

From the basics to applications, how does it affect our livesThe basic concepts ...

The solution to the obvious flash and ejector pin marks at the water passage position of the mold

2025-08-10

The solution to the obvious flash and ejector pin marks at the water passage pos...