Solutions for trapped gas burning, surface wire clamping and insufficient glue in the inner column of the mold

Solutions for trapped gas burning, surface wire clamping and insufficient glue in the inner column of the mold

The trapped gas in the mold is scorched

Phenomenon: The product is trapped in gas and scorched.

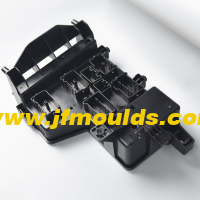

The reason is that the battery compartment of the product is fully sealed with glue without cutting inserts. During the molding process, gas can easily escape from the mold, resulting in gas trapping in the product.

Analysis: The speed setting is unreasonable. If the speed is too fast, it will cause the molten material to intensify the shearing and generate high temperatures. The molten material is prone to decomposition, and the produced gas cannot be discharged outside the mold. The speed in the second section is too high; The mold has poor exhaust.

(1)Characteristics of injection molding machines

Grade: DEMAG100T, Clamping force: 100t, plasticizing capacity: 61g.

(2) Mold characteristics

Mold ejection number: 1×1, glue feeding method: small water inlet (four-point glue feeding), ejection method: Ejection by ejector pins and inclined ejector pins, mold temperature: 105°C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC HP5004-100, product weight (single piece) : 13.7g, sprue weight: 9.06g.

(4) Analysis of causes of defects

1.Due to the excessive speed causing high shear, the molten material heats up rapidly in an instant, resulting in the decomposition of the raw material and the generation of gas. However, the generated gas cannot be discharged from the mold in time.

2. Poor exhaust system of the mold caused the trapped gas to burn.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. The second section can be filled slowly and in a small position near the glue inlet. In the third section, fill 90% of the mold cavity at a relatively fast speed to prevent the high-temperature molten rubber from cooling down. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, and finally switch to the pressure-holding switching position.

3. Cut the exhaust plate at the rear mold of the battery compartment or add a ejector pin for exhaust.

Injection molding process table

Injection molding machine: DEMAG100T, Type B screw, injection volume: 61g | Product Name: DC888 Bottom Shell | ||||

Raw materials: ABS+PC HP 5004-100 | Color: Transparent | Drying temperature: 120°C | Drying method: Dehumidifying dryer | Drying time: 4 hours | Recycled material usage: 0 |

Finished product weight: 13.7g | Nozzle weight: 9.06g | Mold output: 1×1 | Gate injection method: Small water gate injection (dot injection) | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 105°C | 105°C |

| 280°C | 270°C | 265°C | 245°C | / | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 105°C | 100°C |

| △ | △ | △ | △ | △ | ||||

| 55 | 85 | Holding pressure | Pressure-holding position | 125 | 125 | 125 | 125 | Injection pressure | |

| 1.0 | 1.2 | Holding pressure time | 14 | 21 | 29 | 43 | Injection pressure position | ||

Residual amount of injection glue | / | / | / | 16 | 45 | 20 | 55 | Injection velocity | |

| 5.8 | / | / | / | 14 | 21 | 29 | 23 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1.2 | 1.5 | 10 | 25 | 5.2 | 20 65 65 | 10 | 48 | 1.6 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 0.8 | 10 | 880kN | 43 | 1 | 20 25 28 | / | / |

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The surface wire clamping and the inner column of the mold have less glue

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 140t, Plasticizing capacity: 133g.

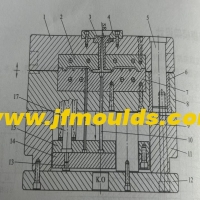

(2) Mold characteristics

Mold ejection number: 1×1, glue injection method: direct injection, ejection method: push plate ejection, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: ABS, Color: Original color, Product weight (single piece) : 4g, nozzle weight: 8g.

(4) Analysis of causes of defects

1.In terms of product structure, the product is a square box-shaped one, and the gluing method is diagonal gluing. At the convergence point of the two streams, there will naturally be wire clamping and trapped air.

2. There is no exhaust system at the convergence point of the two streams on the mold, which cannot expel the gas inside the rubber compound. As a result, trapped gas leads to wire clamping and insufficient rubber.

(5) Countermeasures

Make an exhaust system (insert) at the corresponding position where trapped gas is generated on the mold to expel the gas in the rubber compound.

Injection molding process table

| Injection molding machine: Haitian 120T, Type B screw, injection capacity 133g | |||||

Raw material: ABS | Colour: Black | Drying temperature :80°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 2g×4=8g | Nozzle weight: 8g | Mold output: 1×1 | Gate injection method: Direct injection type | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 80°C | 65°C |

| 230°C | 225°C | 215°C | 215°C | 200°C | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 80°C | 65°C |

| △ | △ | △ | △ | △ | ||||

| / | / | 70 | Holding pressure | Pressure-holding positio | 110 | 98 | 80 | Injection pressure | |

| / | / | 1 | Holding pressure time | 36 | 16 | 10 | Injection pressure position | ||

Residual amount of injection glue | / | 1 | / | 10 | 22 | 65 | Injection velocity | ||

| 6.8 | / | / | / | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 2 | 8 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 5 | 80 | 45 | 1 | 15 35 38 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

How can the frequent breakage of the water inlet needle of the mold, the raised bone position and the excessive glue on the side (flash) be solved

2025-08-22

How can the frequent breakage of the water inlet needle of the mold, the raised ...

Exhaust the parting surface of the mold

2025-10-15

Exhaust the parting surface of the moldThe exhaust grooves on the parting surfac...

Mold exhaust (2)

2025-10-16

Mold exhaust (2)One: Insert exhaustIn the thin-walled structure cavity, the end ...

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

Exhaust the breathable steel of the mold

2025-10-17

Exhaust the breathable steel of the mold Permeable steel is a sintered allo...

Injection Mold Base Design (I)

2025-09-26

Injection Mold Base Design (I) The selection of the mold structure is of gr...