Thread demolding

Thread demolding

(1) Forced demolding of the thread

The mold structure of the thread forced release is simple, but the precision of the plastic part is not high, and it is suitable for the screw of arc or trapezoidal section. For rectangular or near-rectangular threads, the screw is sheared when forced to escape, and for standard triangular threads, due to the cusp It is very thin and forced to prolapse easily deformed or scratched.

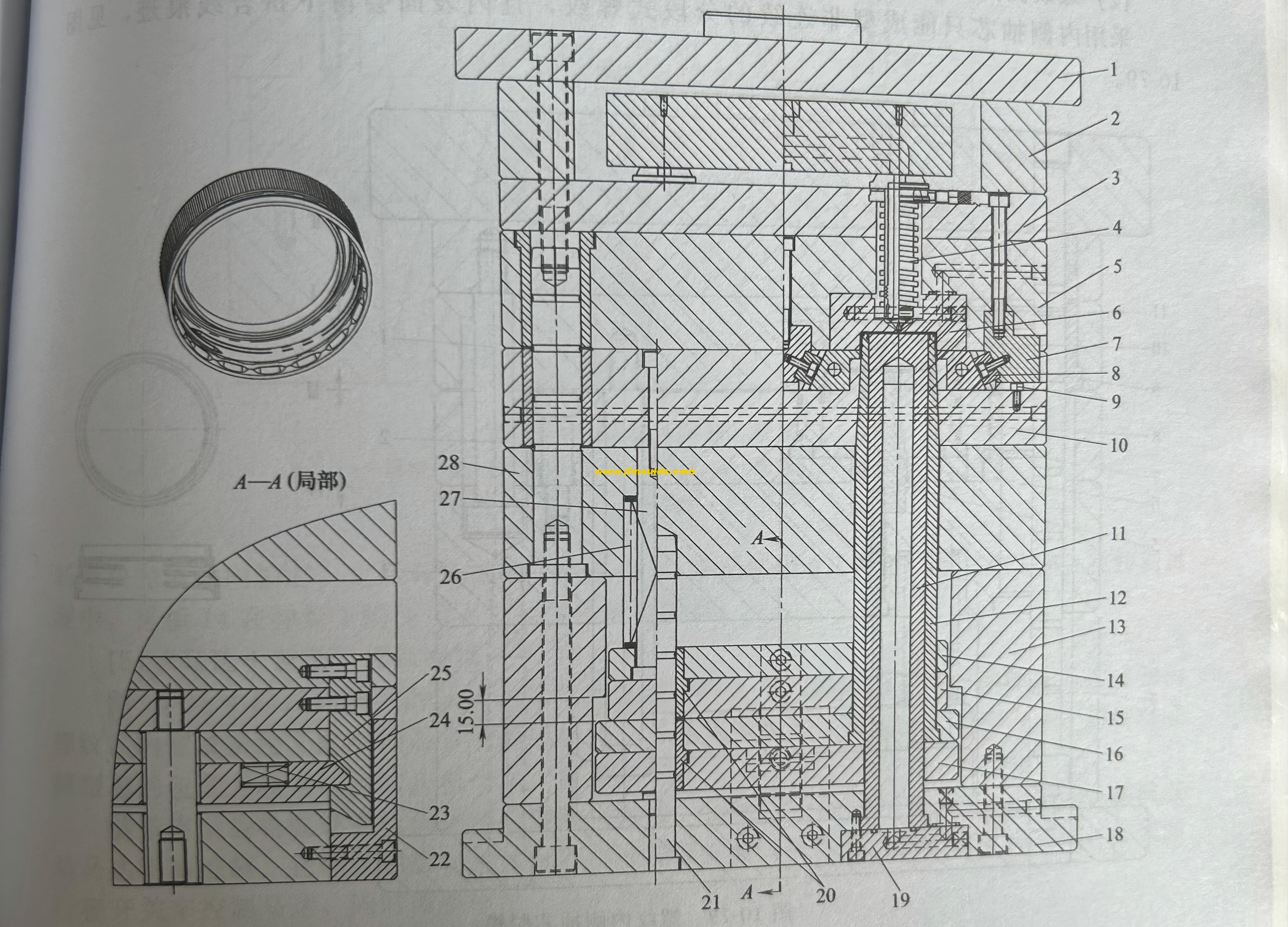

After completing the injection molding, the moving and fixed mold parts are opened, and the lateral core pulling is completed in the process of opening. After that, the top rod of the injection molding machine pushes the first set of push rod plates 14 and 15 through the moving template 28, and under the action of the pull hook 25 and the movable block 24, the second group of push rod plates 16 and 17 move forward with the first set of pusher plates, that is, the moving mold moving core 12 moves together with the plastic part and the push plate 10, in this process, the moving mold fixed core 11 fixed on the mold bottom plate is separated from the plastic part; When two sets of actuator plates are 15mm together, the push block 22 pushes the movable block 24 away from the hook 25, and the first and second sets of actuator plates are separated: the second set of actuator plates together with the movable core on the actuator plate stops moving, while the first set of actuator plates 14 and 15 continue to move forward. The reset rod 27 on the first set of push rod plates pushes the push plate 10, forcibly pushes the plastic parts away from the moving mold core 12, and the mold completes an injection molding.

(2) Thread lateral core pulling and demolding

The use of inner core pulling can only form non-continuous segmented threads. And the inner surface will leave traces of splicing lines. Male threads with external core pulling will also leave mating lines on the thread surface, which is suitable for plastic parts that do not require high precision.

(3) "Motor ten gear" thread demolding

The mold is driven by a motor to drive the gear, and then the gear drives the thread core to demold the thread core of the internal thread automatic release machine The thread core only rotates, does not move axially, and the plastic part is detached from the mold under the push of the threaded core. The mold is driven by a motor to drive the gear, and then the gear drives the external thread automatic release mechanism of the threaded core demolding, while the threaded core rotates, while moving axial under the guidance of the guide sleeve 10, exiting the plastic part Because the threaded core will give the plastic part a large torque during the rotation process, so when using the threaded core automatic demolding, the plastic part must have a stop structure.

(4) "Motor + worm gear" thread demolding

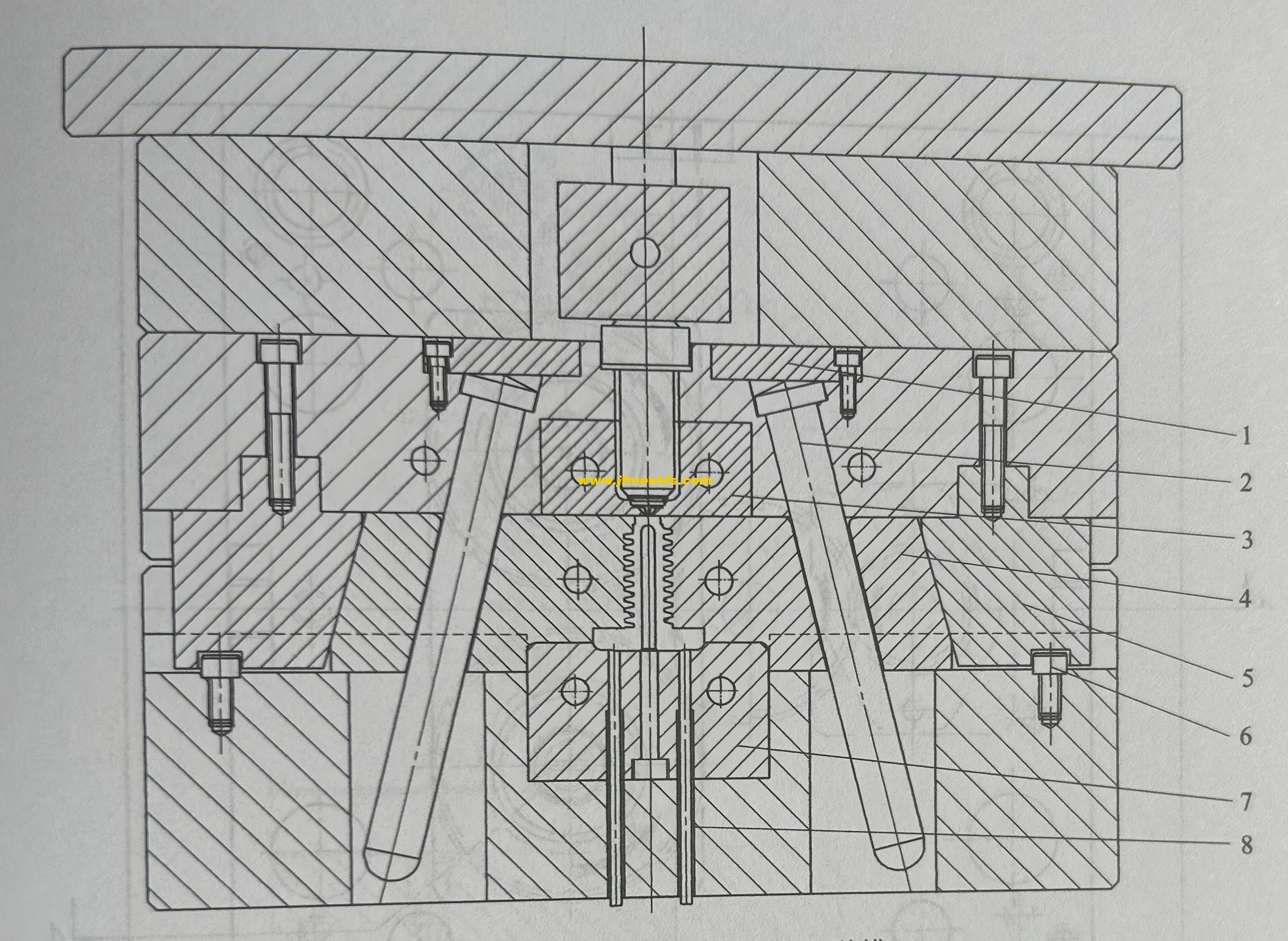

The motor drives the worm gear transmission, and finally drives the threaded core demolding. When the mold is opened, the mold setting inclined slider completes the lateral core pulling, and then the motor starts, the worm gear 9 is driven by the worm 10, and then the threaded core 6 is driven, and during the rotation process, the push plate 14 pushes the plastic part away from the mold under the action of spring 1

(5) "Motor + chain" thread is unchecked

The mold uses an example of a motor driving the threaded core through a chain. The plastic parts have external threads and internal threads, the internal thread adopts the thread core automatic release mechanism, the external thread adopts lateral core pulling molding, due to the large clamping force of the plastic parts to the model core, in order to prevent the plastic parts from sticking to the model core 14, the mold adopts a delay core pulling structure chain drive gear dethreading mechanism is suitable for the occasion of many thread turns, long rotation stroke and inconvenient to do racking, its disadvantage is that the motor is not easy to control. When the threaded shaft rotates in place, it is easy to lock the threaded shaft, so when the threaded shaft moves up and down, a travel switch must be added to control the motor, and a driven shaft needs to be added.

(6) Screw thread demolding

The spiral rod dethreading mechanism is divided into "spiral rod gear" dethreading and "spiral rod ten sprocket" unthreading. The screw dethreading mechanism is to directly pull the screw rod in the process of mold opening, so as to drive the gear or sprocket to demold the threaded core. The spiral rod is a standard part, and this structure is more expensive and generally rarely used.

(7) "rack + gear" thread demolding

An example of lateral core pulling of the back cover die thread of the mobile phone. When opening the mold, the inclined guide column toggles the slider to do lateral core pulling, and at the same time, the gear rack 10 assembled on the fixed mold pushes the gear shaft 12, the gear shaft 12 drives the large gear 9 to rotate through the flat key 8, and the large gear 9 threaded core rotates while retreating under the guidance of the guide nut 6, and slowly separating from the plastic

Then drive the thread core 2 to rotate, and when the die is closed, the rack 10 drives the thread core 2 to reset, and the wedge tightening block pushes the slider to reset. Before clamping, the push rod must be in part to achieve automatic thread demolding. Returned to its original position, the mold is controlled by a stroke switch 13.

Related News

Injection molds: The Cornerstone and Future Trend of Precision Manufacturing

2025-07-12

Injection molds: The Cornerstone and Future Trend of Precision ManufacturingBasi...

How can the surface dirt, water line inclusion and warping deformation of the mold be solved

2025-08-30

How can the surface dirt, water line inclusion and warping deformation of the mo...

In-depth analysis of injection mold industry: current situation, challenges and opportunities

2025-07-05

In-depth Analysis of the Injection Mold Industry: Current Situation, Challenges ...

Injection molds: The hidden champions in industrial manufacturing

2025-07-14

Injection molds: The hidden champions in industrial manufacturing In the vast...

Exploring Injection Molds: Unlocking the Core Code of Plastic Molding

2025-07-10

Exploring Injection Molds: Unlocking the Core Code of Plastic Molding In the ...

In-depth Analysis of Injection Molds: A Full-Process Exploration from Design to Application

2025-07-10

In-depth Analysis of Injection Molds: A Full-Process Exploration from Design to ...