The solution to the problem of the lens length dimension of the mold being too large and the water line being clamped on the side of the middle hole position

The solution to the problem of the lens length dimension of the mold being too large and the water line being clamped on the side of the middle hole position

The length dimension of the lens in the mold is too large

Phenomenon: The length dimension of S02 lens No. 1 is too large

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 50t, plasticizing capacity: 133g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: direct injection into the gate, ejection method: push plate ejection, mold temperature: 75°C (constant temperature machine)

(3) Product characteristics

Material: PMMA, Color: White, Product weight (single piece) : 1.5g, nozzle weight: 4g.

(4) Analysis of causes of defects

1.The dimensions of the two mold cavities do not match, resulting in inconsistent product dimensions.

2. The mold is for 1×2 pieces of products. The size of 1# is relatively large because it was injected under the same molding process conditions, and the dimensions of the two products are not the same.

3. When the size of No. 2 was adjusted to be qualified, a flash occurred at the jaw of No. 1 parting surface, causing the size to be 0.05mm larger. However, when the size of No. 1 was adjusted to be qualified, the size of No. 2 was smaller.

(5) Countermeasures

With the No. 1 cavity remaining stationary, the cavity length of the No. 2 product, which is relatively small in size, was treated with 0.05mm of glue.

Injection molding process table

Injection molding machine: Haitian 120T, Type B screw, injection volume: 133g | Product Name: Chassis Bottom shell | ||||

Raw material: PMMA | Colour: White | Drying temperature: 80°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 1.5g×2=3g | Nozzle weight: 4g | Mold output: 1×2 | Pouring method: Submersible direct pouring type | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 85°C | 65°C |

| 275°C | 260°C | 255°C | 250°C | 240°C | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 85°C | 65°C |

| △ | △ | △ | △ | △ | ||||

| / | 81 | 98 | Holding pressure | Pressure-holding position | 70 | 90 | 100 | Injection pressure | |

| / | 1 | 1.2S | Holding pressure time | 10 | 23 | 28 | Injection pressure position | ||

Residual amount of injection glue | / | / | 32 | 45 | 62 | Injection velocity | |||

| 6.2 | / | / | / | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 1.5 | 8 | 35 | 5 | 10 15 10 | 10 | 55 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 80 | 45 | 1 | 15 3 38 | / | / |

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

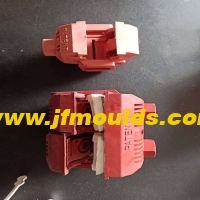

Water lines are clamped on the side of the middle hole position of the mold

Phenomenon: Water marks are prone to appear on the side of the middle hole position during molding.

Analysis: The technician believes that the mold exhaust is poor and requests mold repair. When the injection molding speed is increased, water marks are always present and cannot be significantly improved.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 100g.

(2) Mold characteristics

Mold ejection quantity: 1×2, glue feeding method: submerged glue feeding, ejection method: Ejection by ejector pin, mold temperature: 90°C (constant temperature machine)

(3) Product characteristics

Material: ABS 757 37827, Color: Silver black, Product weight (single piece) : 3.1g, spout weight: 1.8g

(4) Analysis of causes of defects

Due to the thin structure of the product, the depth of the front mold cavity is relatively shallow, and the mold is transported with water separately, the mold temperature is prone to be low.

2. The injection molding speed is relatively slow.

3. The location and travel are unreasonable.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel rubber opening at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the rubber inlet at a slow speed and a very small position. In the third section, use rapid charging to pass through the fusion area of the middle hole position to avoid forming a fusion line. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Injection molding process table

Injection molding machine: Haitian 86T, Type A screw, injection volume: 100g | Product Name: Razor Switch Lever | ||||

| Raw materials: ABS PA757 with silver powder | Color: Silver-black | Drying temperature: 85°C | Drying method: Dehumidifying dryer | Drying time :2 hours | Recycled material usage: 0 |

Finished product weight: 3.1g×2=6.2g | Nozzle weight: 1.8g | Mold output: 1×2 | The method of pouring glue into the gate: pouring glue into the water | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 90°C | 85°C |

| 230°C | 220°C | 210°C | 160°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 90°C | 85°C |

| △ | △ | △ | △ | △ | ||||

| / | 80 | 100 | Holding pressure | Pressure-holding position | 100 | 115 | 110 | Injection pressure | |

| / | 0.2 | 0.5 | Holding pressure time | 8 | 6 | 10 | 25 | Injection velocity | |

Residual amount of injection glue | / | / | / | / | / | 8 | 14 | 23 | Velocity of fire position |

| 7.8 | / | / | / | / | 2.5 | / | / | / | Injection time |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 1.2 | 7 | 18 | 5 | 10 15 10 | 10 | 24 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 120 | 45 | 1 | 15 35 38 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Solutions for burrs, sticking to the mold, wire clamping and deformation of the mold

2025-09-01

Solutions for burrs, sticking to the mold, wire clamping and deformation of the ...

Limit pins and springs of the mold

2025-10-04

Limit pins and springs of the moldOne: Limit pinThe function of the limit nail i...

Plastic parts

2025-09-15

Plastic partsOne: Dimensional accuracy of plastic partsThe dimensional accuracy ...

How can the frequent breakage of the water inlet needle of the mold, the raised bone position and the excessive glue on the side (flash) be solved

2025-08-22

How can the frequent breakage of the water inlet needle of the mold, the raised ...

The solution to the problem of the lens length dimension of the mold being too large and the water line being clamped on the side of the middle hole position

2025-08-11

The solution to the problem of the lens length dimension of the mold being too l...

Mainstream path design

2025-10-21

Mainstream path design From the perspective of reducing pressure and heat l...