How can the frequent breakage of the water inlet needle of the mold, the raised bone position and the excessive glue on the side (flash) be solved

How can the frequent breakage of the water inlet needle of the mold, the raised bone position and the excessive glue on the side (flash) be solved

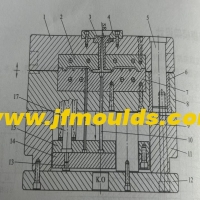

The needle at the water inlet of the mold often breaks

Cause: Unbalanced ejection of the push plate leads to needle breakage. Double ejection rods were used for ejection but only a single rod was used for ejection.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 140t, Plasticizing capacity: 133g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: submersible gate, ejection method: push plate ejection, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: PC, Color: Gray, Product weight (single piece) : 2g, nozzle weight: 6g

(4) Analysis of causes of defects

The mold is a 1×2 piece product and is also designed with double ejection rods. Under normal production conditions, double ejection rods should be used for ejection. However, in multiple production

processes, technicians have always used single rods, which has led to an imbalance in the ejection of the ejection pin plate. The imbalance in the ejection of the upper and lower parts of the ejection pin plate has caused the water inlet to frequently break.

(5) Countermeasures

Use double ejector pins to push out at the same distance to ensure that the upper and lower ends of the ejector pin board are pushed forward at the same distance, which can enable all ejector pins to be smoothly and evenly pushed forward by the ejector pin board at the same distance.

Automobile bumper mold Manufacturer in China (jfmoulds.com)

The bone position of the mold is raised

Phenomenon: During the production of transparent sliding accessories, there is a phenomenon of bone position dragging and swelling.

Analysis: If the holding pressure is slightly higher and the duration is longer, the short bone position will be elevated; if the pressure is too low, it will shrink. If the speed is too slow, orange peel will appear on the surface. The overall forming process configuration is unreasonable.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 120t, Plasticizing capacity: 150g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 95°C for front and rear molds (constant temperature machine)

(3) Product characteristics

Material: PC K30, Color: Transparent blue, Product weight (single piece) : 1.5g, nozzle weight: 13g

(4) Analysis of causes of defects

The pressure-holding setting is too early and too high, and the pressure-holding time is too long.

2. The cooling time of the product before demolding is insufficient.

3. The system back pressure needs to be set to assist in molding.

4. Fill the mold in multiple stages.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the runner opening to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a

slow speed and a very small position. In the third section, fill 90% of the mold cavity quickly to prevent the high-temperature molten glue from cooling and forming wavy patterns. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

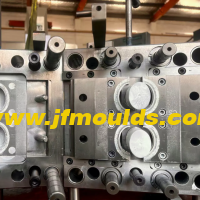

The side of the mold is covered with multiple layers of glue (flash)

Reason: The alignment was not in place.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force: 140t, Plasticizing capacity: 133g

(2) Mold characteristics

Mold ejection number: 1×4, glue injection method: submersible gate, ejection method: push plate ejection, mold temperature: 85°C (constant temperature machine)

(3) Product characteristics

Material: PC, Color: Black, Product weight (single piece) : 2g, nozzle weight: 8g

(4) Analysis of causes of defects

1. The base of the shovel repositions, causing the line to fail to hit the target properly and resulting in a flash.

2. The wear of the base of the shovel and the slope of the buried position causes the position to fail to touch the ground properly, resulting in burrs.

(5) Countermeasures

Just insert the row position into the welding pad and it's done.

Related News

Determination of mold base size

2025-09-29

Determination of mold base size1: Determine the length, width and height of the ...

The dimensional tolerance of injection mold fit and the surface roughness of mold parts

2025-09-12

The dimensional tolerance of injection mold fit and the surface roughness of mol...

Injection Mold Base Design (I)

2025-09-26

Injection Mold Base Design (I) The selection of the mold structure is of gr...

In-depth Insights into the Injection Mold Industry: Technological Iteration, Market Landscape, and New Paradigms for Sustainable Development

2025-07-03

In-depth Insights into the Injection Mold Industry: Technological Iteration, Mar...

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...

Injection Mold Base Design (Part Two)

2025-09-27

Injection Mold Base Design (Part Two) One: Double pusher plate injection mo...