Solutions for burrs, sticking to the mold, wire clamping and deformation of the mold

Solutions for burrs, sticking to the mold, wire clamping and deformation of the mold

The burrs on the mold

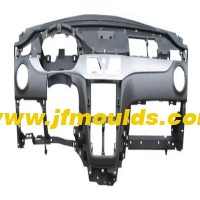

Phenomenon: During the production process of the front shell decorative parts of the casing products, there are burrs on the PL surface and the latch position.

Analysis: The design of the mold's water outlet is unreasonable. To adjust the product, there are multiple bone position shrinkage marks, and burrs appear on the PL surface and the buckle position of the product.

Characteristics of injection molding machines

Grade: HT-DEMAG, clamping force: 100t, Plasticizing capacity: 90g

(2) Mold characteristics

Mold ejection number: 1x1, injection method: lap gate, ejection method: Ejection by ejector pin, mold temperature :115℃ (constant temperature machine)

(3) Product characteristics

Material :ABS+PC, Color: Gray, Product weight (single piece) : 5.5g, nozzle weight: 3.3g

(4) Analysis of causes of defects

The mold's glue inlet method is lap joint glue inlet. The design of the mold's water inlet is unreasonable. To adjust the shrinkage marks at multiple bone positions of the product, the product L

There are burrs on the surface and the buckle position.

(5) Countermeasures

1. Add one glue inlet, modify the mold to change the cold material position to one glue inlet, but add two weld lines that are prone to breakage.

2. Change the original ABS+PC material to PC material to enhance toughness and improve the tendency of weld lines to break easily.

Automobile parts mold Manufacturer in China (jfmoulds.com)

Mold sticking

Phenomenon: The protective plug of the casing product is prone to sticking to the front mold during the production process.

Analysis: The product appearance of the mold design is textured, making it difficult to exit the mold.

Characteristics of injection molding machines

Grade :HT-50T, clamping force :50, plasticizing capacity: 60g

(2) Mold characteristics

Mold ejection number :1x4, injection method: lap gate, ejection method: Pin insertion ejection, mold temperature :45° C/65 ° C (constant temperature machine)

(3) Product characteristics

Material :TPU, Color: Black, Product weight (single piece) : 1.5g, nozzle weight :3.3g

(4) Analysis of causes of defects

The mold's glue injection method is lap injection, and the mold design makes the product appearance textured, which is not easy to exit the mold. The rear mold insert is made of soft material

The rubber compound fails to assist in demolding, causing the product to stick to the front mold.

(5) Countermeasures

Adopt the temperature difference between the front and rear molds. The high temperature of the front mold facilitates demolding.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Wire clamping and deformation of the mold

Phenomenon: During the production process of transparent lenses, there are often issues such as wire clamping and deformation.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. Poor exhaust on the mold surface.

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 50, plasticizing capacity: 64g

(2) Mold characteristics

Mold ejection quantity: 1×2, glue type: fan-shaped pouring, ejection method: Ejection with ejector pins, mold temperature :80 ° C (constant temperature machine)

(3) Product characteristics

Material: PMMA 8N, Color: Transparent, Product weight (single piece) :33.8g, nozzle weight: 5.3g

(4) Analysis of causes of defects

The main channel of the mold is very large. The way of feeding the molten material is fan-shaped feeding. The molten material flows to the area near the feeding port. Due to the excessive speed and the surface of the mold

The surface is very smooth, causing high shear and making the molten material heat up rapidly in an instant. It causes the raw materials to decompose and produce gas, which is not discharged in time and leads to changes Shape and wire clamping.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. Add cold material Wells and additional exhaust openings at the locations where wire clamping occurs.

3. Slow down the injection speed at the places where wire clamping occurs, and the gas is also easier to be discharged.

Related News

Calculation of injection mold forming dimensions

2025-10-10

Calculation of injection mold forming dimensionsI. Calculation Method for Genera...

The selection of mold base specifications and models

2025-09-28

The selection of mold base specifications and models(1) Selection of two-plate m...

Solution for mold fracture and air wrinkle treatment

2025-08-08

Solution for mold fracture and air wrinkle treatmentFracture of the moldPhenomen...

Determination of mold base size

2025-09-29

Determination of mold base size1: Determine the length, width and height of the ...

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of Change

2025-07-04

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of...

How can the top white and surface elevation of the mold be solved

2025-08-26

How can the top white and surface elevation of the mold be solvedThe top white o...