The solution to the obvious flash and ejector pin marks at the water passage position of the mold

The solution to the obvious flash and ejector pin marks at the water passage position of the mold

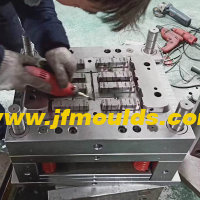

The water passage holes of the mold are flapped

Phenomenon: During the formation of the washing machine, the small water passage hole in the middle of this product is prone to flash

Analysis: The technician believes it is a mold issue and requests to rent a mold repair service. The product material contains pp material, and the temperature should not be too high.

Characteristics of injection molding machines

Grade: Zhen De, clamping force: 260t, plasticizing capacity: 250g.

(2) Mold characteristics

Mold ejection quantity: 1×2, glue injection method: dot injection, ejection method: Ejection by ejector pin, mold temperature: 50°C (constant temperature machine).

(3) Product characteristics

Material: PP+20%GF, Color: black, product weight (single piece) : 43g, nozzle weight: 10.8g.

(4) Analysis of causes of defects

1. The insert for this hole position on the mold of the product must be rubbed diagonally, as it is stronger in the vertical direction.

2. The temperature of the glue melting and the mold temperature are both on the high side.

3. The injection speed of the glue is too fast.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the glue inlet at a relatively fast speed to 2/5 of the product. In the third section, fill the small holes on the product at a slow speed. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Injection molding process table

Injection molding machine: Zhende 260T, Type A screw, injection volume: 250g | Product Name: Razor Washer | ||||

Raw materials: PP+20%GF | Colour: Black | Drying temperature: 95°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 43g×2=86g | Nozzle weight: 10.8g | Mold output: 1×2 | The method of pouring glue into the gate: dispensing glue | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 50°C | 47°C |

| 220°C | 210°C | 200°C | 160°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 50°C | 45°C |

| △ | △ | △ | △ | △ | ||||

| 80 | 100 | Holding pressure | Pressure-holding position | 100 | 110 | 100 | 110 | Injection pressure | |

| 0.5 | 1.0 | Holding pressure time | "End | 16 | 16 | 18 | 35 | Injection velocity | |

Residual amount of injection glue | / | / | / | / | 20 | 50 | 70 | Velocity of fire position | |

| 7.8 | / | / | / | / | 4.8 | / | / | / | Injection time |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 4.8 | 24 | 48 | 5 | 10 15 10 | 10 | 80 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 250 | 45 | 1 | 15 35 38 | / | / |

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

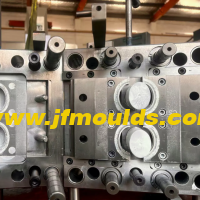

The pin marks on the mold are obvious

Phenomenon: The pin marks on the product surface are obvious

The reason is that when the product is saturated, the surface pin marks are relatively shallow, but the size exceeds the tolerance range by a large margin.

Analysis: The mold size is not reasonably made, which makes it difficult to improve both the size and the ejector pin mark simultaneously.

Characteristics of injection molding machines

Grade: DEMAG100T, Clamping force: 100t, plasticizing capacity: 61g.

(2) Mold characteristics

Mold ejection number: 1×1, glue injection method: small water outlet (dot injection), ejection method: Ejection by ejector pin, mold temperature: 105°C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC, product weight (single piece) : 2.14g, nozzle weight: 1.98g.

(4) Analysis of causes of defects

1. The mold size is not reasonably made. Under the condition of ensuring the product size during machine adjustment, it is rather difficult to control the product ejector mark. When the product is saturated, the top pin marks are relatively shallow, but the size is relatively large.

2. The top pin is too long, resulting in a thin glue position and causing the top pin mark on the product to be more obvious.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a moderate speed and find the corresponding switching position. The second section can be filled slowly and in a small position near the glue inlet. The third section fills 95% of the mold cavity at a moderate speed. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity. Finally, switch to the pressure-holding switching position.

3. Extend the holding time of each section to control the product size.

4. The upper surface of the thimble is polished.

Injection molding process table

Injection molding machine: DEMAG100T, Type B screw, injection volume 61g | Product Name: DC888 Bottom Shell | ||||

Raw materials: ABS+PC HP 5004-100 | Color: Transparent | Drying temperature: 120°C | Drying method: Dehumidifying dryer | Drying time :4 hours | Recycled material usage: 0 |

Finished product weight: 2.14g | Nozzle weight: 1.98g | Mold output: 1×1 | Gate injection method: Small gate injection (point injection) | ||

| Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 105°C | 105°C |

| 280°C | 270°C | 265°C | 245°C | / | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 105°C | 100°C |

| △ | △ | △ | △ | △ | ||||

| 55 | 85 | Holding pressure | Pressure-holding position | 139 | 139 | 139 | 139 | Injection pressure | |

| 2.0 | 3.2 | Holding pressure time | 10 | 13 | 20 | 23 | Injection pressure position | ||

Residual amount of injection glue | / | / | / | 16 | 20 | 23 | 37 | Injection velocity | |

| 4.2 | / | / | / | 10 | 13 | 20 | 23 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1.2 | 1.5 | 16 | 25 | 5.2 | 20 65 65 | 10 | 27 | 1.6 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 0.8 | 10 | 880kN | 43 | 1 | 20 25 28.6 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

The innovative design and intelligent development trend of injection molds

2025-07-09

The innovative design and intelligent development trend of injection molds In...

Calculation of injection mold forming dimensions

2025-10-10

Calculation of injection mold forming dimensionsI. Calculation Method for Genera...

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of Change

2025-07-04

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of...

The selection of mold base specifications and models

2025-09-28

The selection of mold base specifications and models(1) Selection of two-plate m...

In-depth Analysis of the Injection Mold Industry

2025-07-01

In-depth Analysis of the Injection Mold IndustryI. Overview of the Injection Mol...

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...