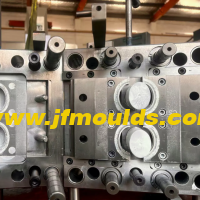

Exhaust the parting surface of the mold

Exhaust the parting surface of the mold

The exhaust grooves on the parting surface are easy to clean, not prone to clogging, and have a good exhaust effect. It is the main place for gas discharge. If the parting surface is a curved or inclined surface, ordinary lathes, ordinary milling machines, CNC milling machines, electrode processing or wire cutting processing are generally used. The roughness of the processed parting surface is relatively high, with Ra generally ranging from 1.6 to 6.3pm, and it can be directly vented. There is no need to reprocess exhaust grooves on the parting surface. If the parting surface is a plane, grinding processing is commonly used. The roughness of the parting surface after grinding processing is relatively low, with Ra ranging from 0.2 to 0.8 μ m. The parting surface adheres closely, and the gas in the cavity is not easy to be discharged. In this case, an exhaust groove must be opened on the parting surface on one side of the cavity. There are two ways to open exhaust grooves on the parting surface: one is to open exhaust grooves locally, and the other is to open exhaust grooves around.

(1) Exhaust grooves are partially opened on the parting surface

This is the most commonly used exhaust method. The approach is to open exhaust slots wherever there is trapped air. The location of the exhaust slots is usually determined after mold testing.

① The depth of the exhaust groove

The depth A of the first-stage exhaust groove varies depending on the type of plastic. The fluidity of the plastic and its ease of degradation should be taken into consideration. Generally speaking, for plastics with good fluidity, the depth of the exhaust groove is 0.015 to 0.025mm. For plastics with medium fluidity, the depth of the exhaust groove is 0.03 to 0.04 mm. For plastics with poor fluidity, the depth of the exhaust groove is 0.05 to 0.06mm. In addition, for easily decomposable plastics, the area (depth X width) of the exhaust groove should be larger. The depth B of the secondary exhaust groove is generally taken as 0.50 to 1.00mm. The secondary exhaust slot must reach the edge of the insert and be in communication with the atmosphere.

② The width of the exhaust groove.

The width D of the exhaust slot mainly depends on the size of the mold cavity. The larger the cavity, the larger the slot width D, but the slot width should not be too large, generally ranging from 5.00 to 15.00mm. The distance between the exhaust slots is 30 to 50mm.

③ Length of the exhaust groove

Due to the shallow exhaust groove, the resistance to gas discharge is large and it is very easy to be clogged by rubber powder. Therefore, the length C of the exhaust groove should not be too long, generally taken as 3.00 to 4.00mm.

Disposable box mold Manufacturer in China (jfmoulds.com)

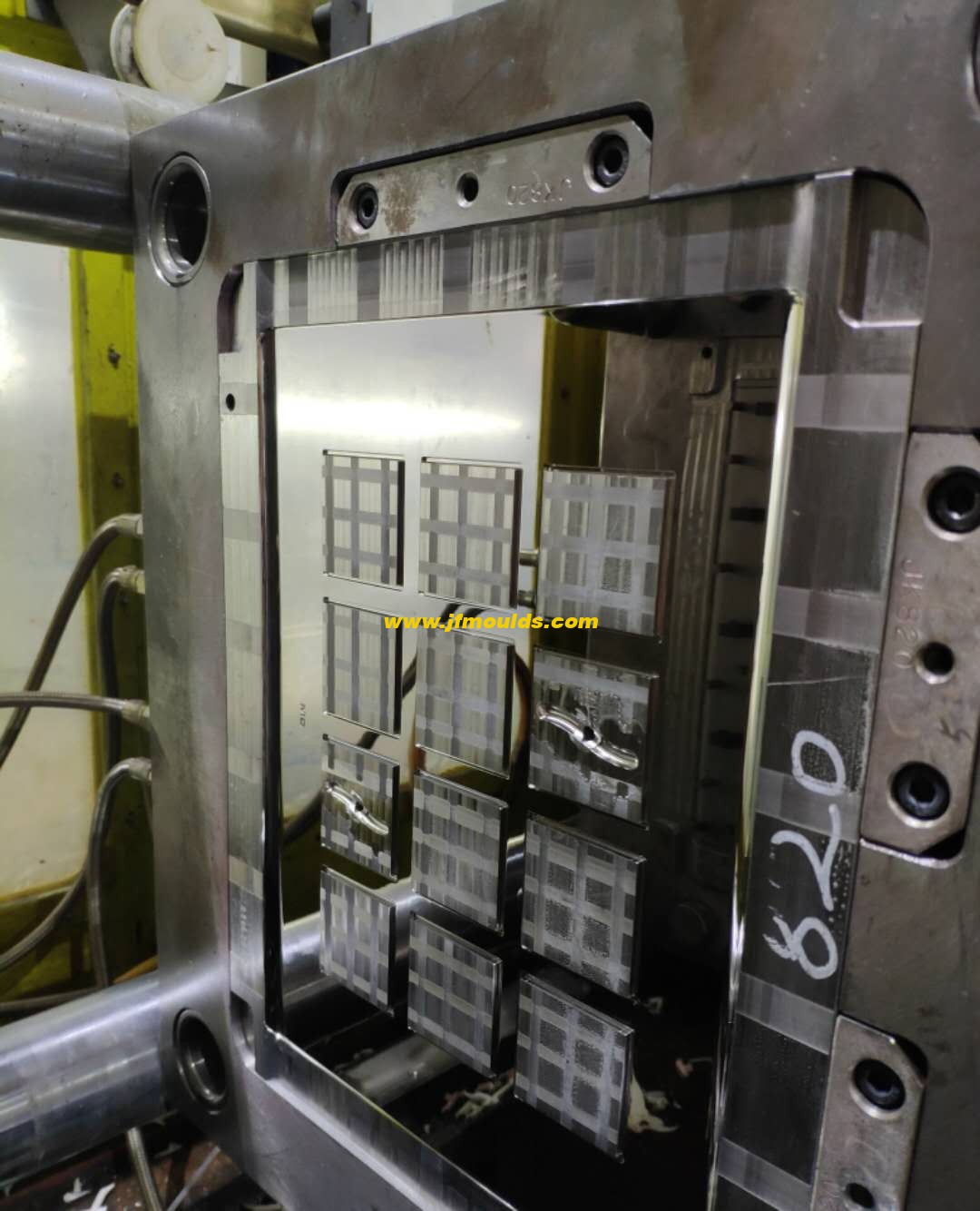

(2) Exhaust grooves should be opened around the parting surface

When the trapped air is particularly severe, the method of opening large areas of exhaust grooves around can be adopted to release the air.

The depth A of the first-stage exhaust groove is the same as the value in the local exhaust groove. The depth B of the secondary exhaust groove is 0.50 to 0.80mm, the depth B1 of the tertiary exhaust groove can be taken as 1.00mm, and the length C1 of the secondary exhaust groove is 5.00 to 6.00mm.

(3) Reduce the contact area of the parting surface to improve the exhaust effect

If the cavity is trapped with air, the contact area of the parting surface can be reduced. To vent air, the sealing surface can be roughened with coarse sandpaper. The width of the contact surface should not be less than 20mm. If the exhaust effect is still not satisfactory at this point, then an additional exhaust slot must be added within the shadow surface.

Two: Venting of the gating system on the parting surface

There is a large amount of gas in both the main runner and the runner of the gating system. During the injection molding process, some of this gas is discharged through the pull channel, some is discharged from the exhaust grooves on the parting surface, and the remaining part enters the cavity with the melt. In principle, the amount of gas discharged by the feed rod (push rod) into the cavity should be as little as possible to reduce the exhaust burden on the cavity. The gas in the gating system should mainly be discharged through the parting surface. The exhaust grooves of the gating system are mainly located at the end of the runner. The width of the exhaust grooves is equal to the diameter or width of the runner, with a length of 3.00 to 4.00mm. The secondary exhaust grooves extend directly to the edge of the mold.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...

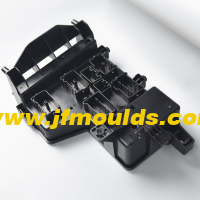

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

Injection molds: From Basic Understanding to Cutting-edge Exploration

2025-07-16

Injection molds: From Basic Understanding to Cutting-edge ExplorationI. Introduc...

The trapped air adjustment of the mold is difficult, and the deformation and the bottom row position pulling mold treatment method of the face shell

2025-08-12

The trapped air adjustment of the mold is difficult, and the deformation and the...

The new business card of "Mold Capital" is fully started.

2025-06-19

Recently, at the construction site of the Huangyan Mould Intelligent Manufacturi...

Mold exhaust (2)

2025-10-16

Mold exhaust (2)One: Insert exhaustIn the thin-walled structure cavity, the end ...