Injection Mold Base Design (I)

Injection Mold Base Design (I)

The selection of the mold structure is of great significance. The structure of the mold determines the injection molding cycle, cost, injection molding process of the plastic part and the production cost of the plastic part, etc. Therefore, caution must be exercised when choosing the mold structure.

(1) Frameless two-plate mold:

Suitable occasions: This result can be used when the plastic part is flat, the lateral projection area is not large and the structure is simple. However, it should be noted that four positioning columns should be added respectively between the punch and die and the template.

Features: The front and rear templates do not require frame opening. The front and rear templates are thinner than traditional molds and do not need mold frames. The processing cycle is short and the cost is low. However, the positioning is not as reliable as that of traditional molds. Generally, a straight side lock or positioning column needs to be added between the moving and fixed mold inserts.

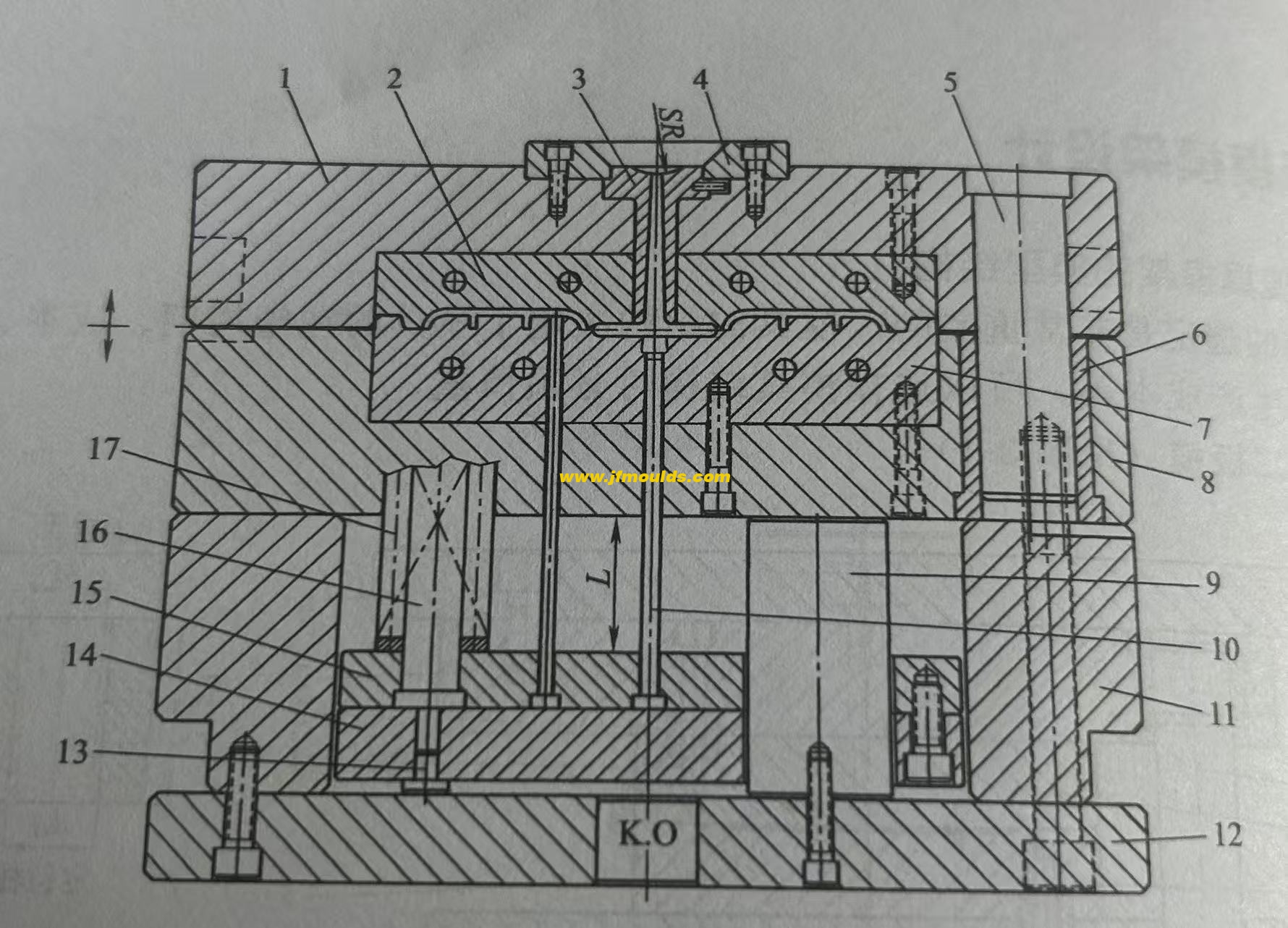

(2) Common flow channel two-plate mold:

1.The K.O hole must not be smaller than the diameter of the top rod of the injection molding machine.

2. When launching stroke L, ensure that the reinforcing ribs can be completely released.

3. When automatic injection molding is required, it is necessary to ensure that the plastic part can be completely removed from the cavity. When operating semi-automatically or manually, it is necessary to ensure that the plastic parts can be easily removed.

4. The spherical radius SR of the gate sleeve must be greater than the nozzle radius.

Plastic trash can mold Manufacturer in China (jfmoulds.com)

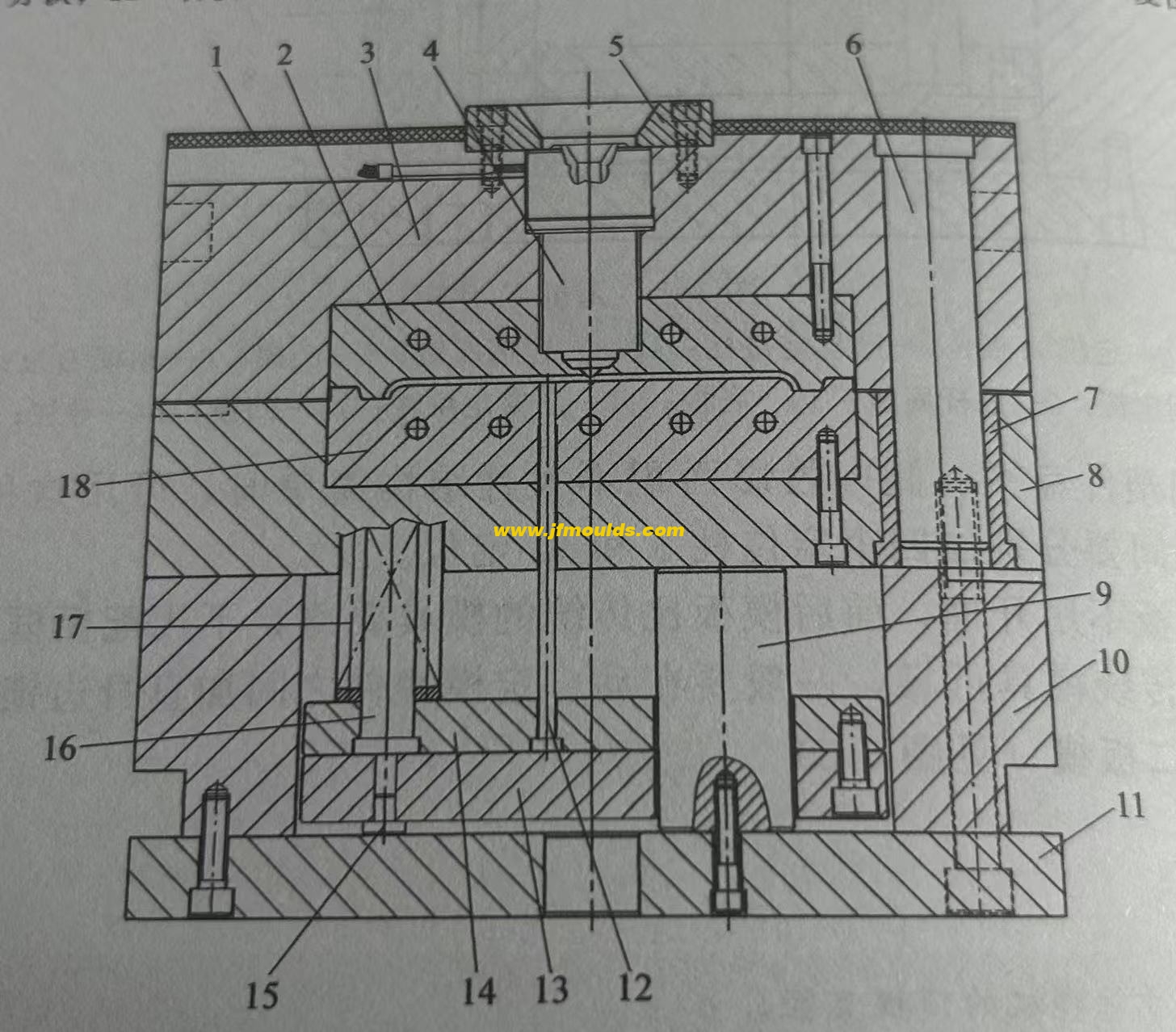

(3) Single-point hot jet nozzle two-plate mold:

1. It is suitable for large products, and the plastics used are ABS, PP, GP, etc.

2. The wires of the thermal control equipment on the heat jet nozzle must be in the groove. They are connected to the power supply outside the mold through the mold.

3. There must be cooling water flowing near the hot jet nozzle.

4. The impact of thermal expansion must be taken into account in the design.

5. Other precautions are the same as those for the common flow channel two-plate mold.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

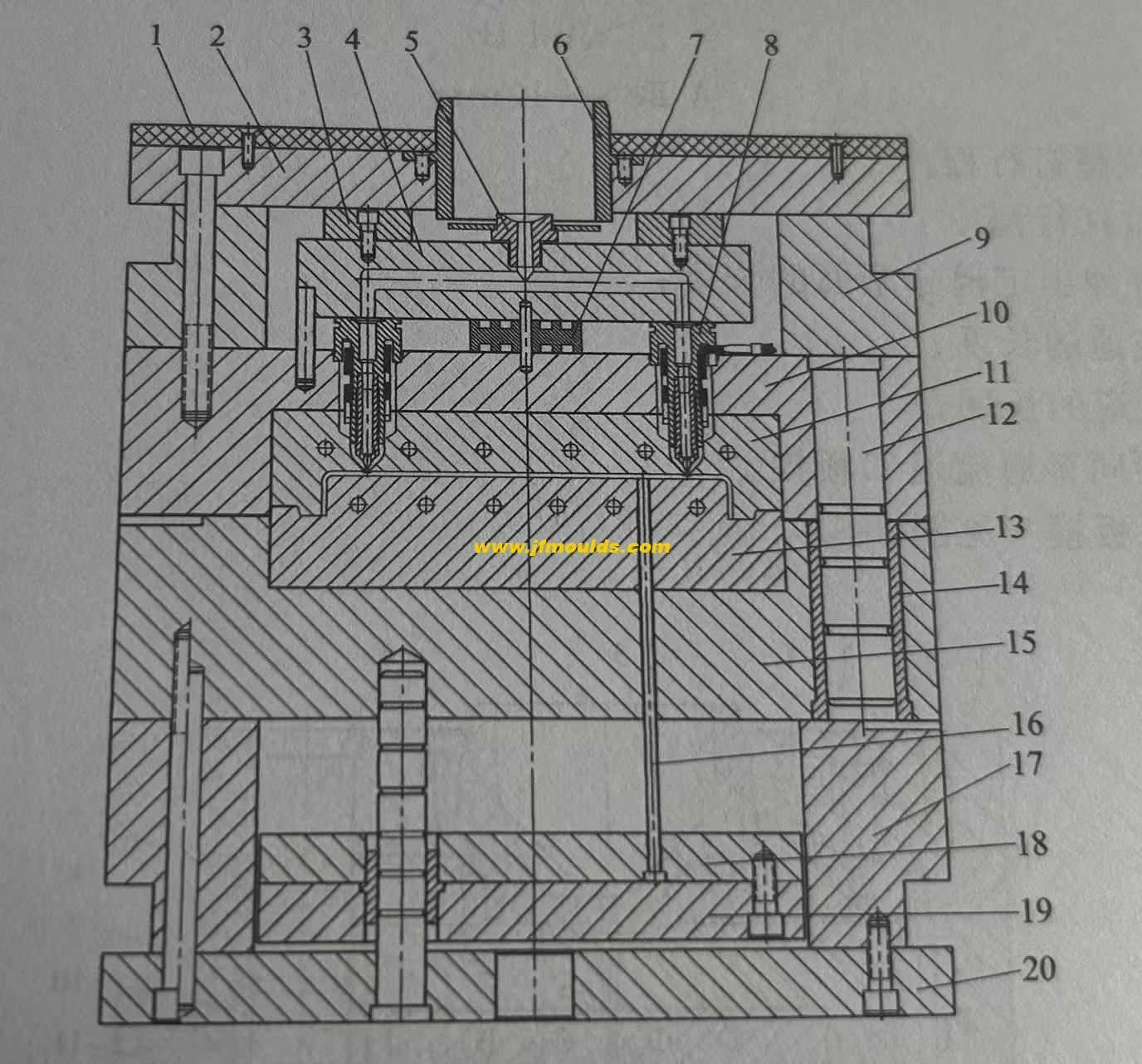

(4) Two-plate mold for multi-point hot runner plates:

1. It is suitable for large products, with one mold and one cavity or multiple cavities in one mold. To better fill the cavity and reduce its warpage deformation, multi-glue feeding is usually adopted.

2. Heating equipment is installed on the hot runner plate.

3. The wires of the thermal equipment on the hot jet nozzle of the hot runner plate must be in the groove and connected to the power supply outside the mold through the mold.

4. There must be cooling water flowing near the hot jet nozzle.

5. The impact of thermal expansion must be taken into account in the design.

6. Other precautions are the same as those for the common flow channel two-plate mold.

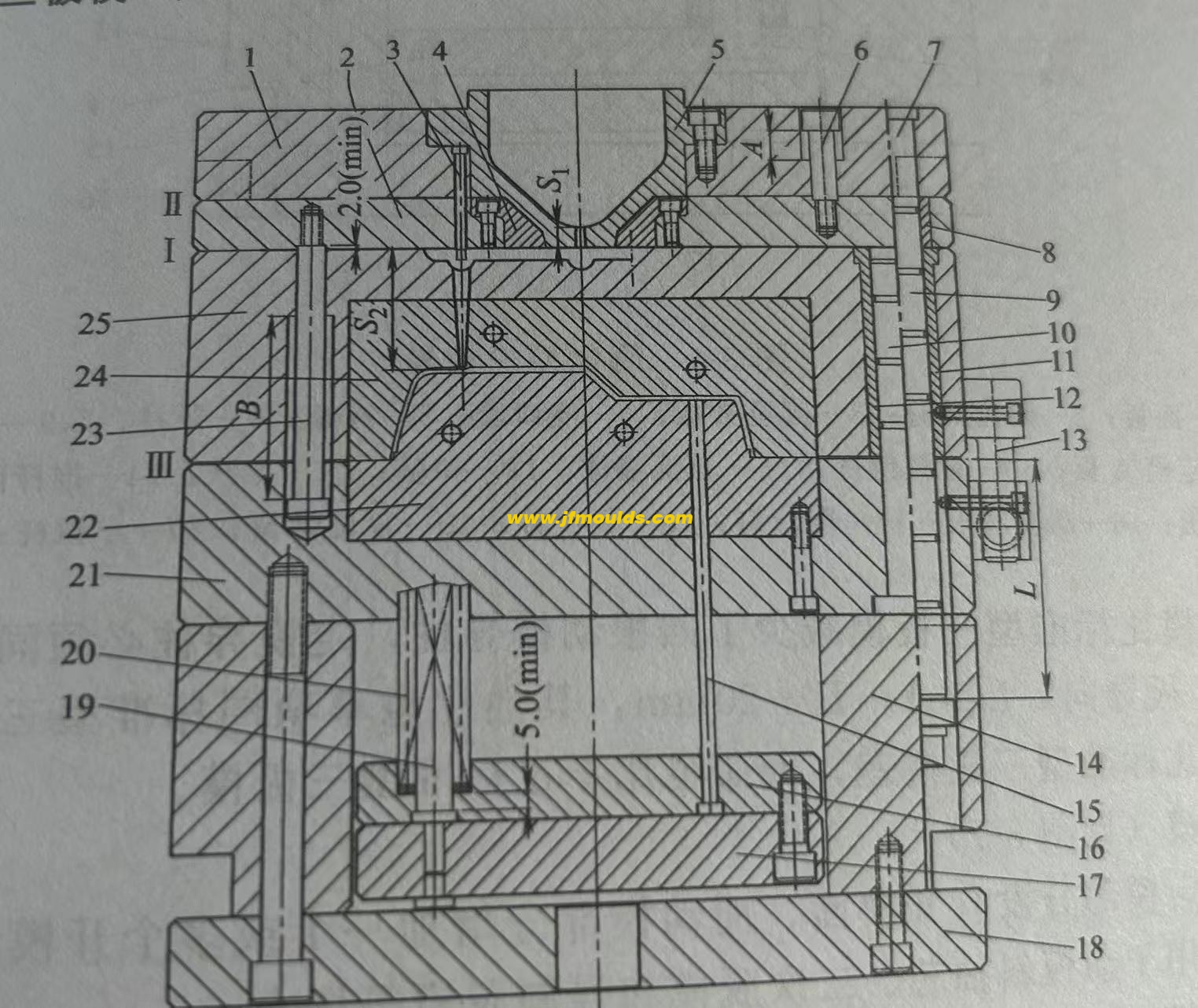

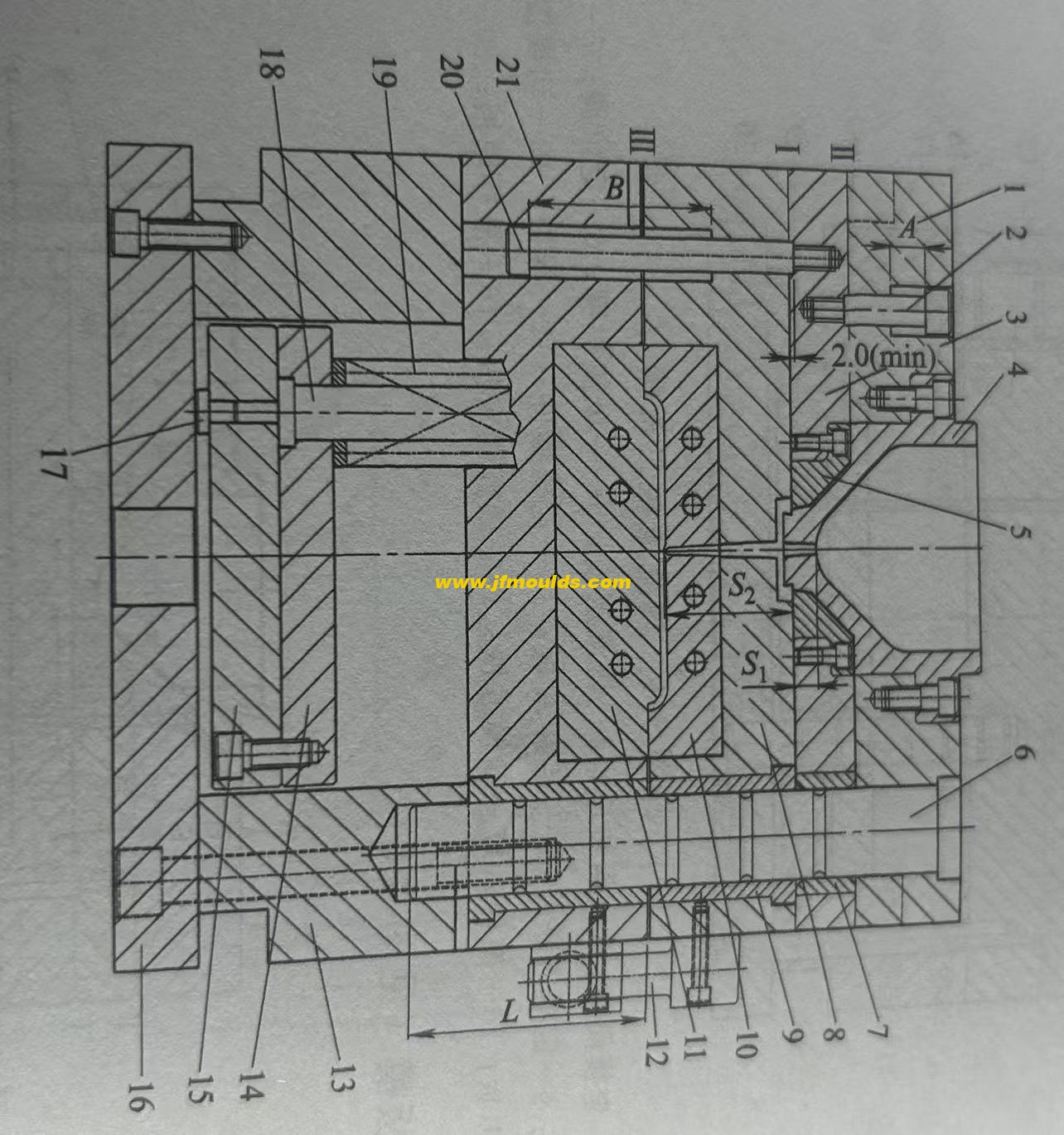

(5) Standard three-board mold:

When designing, the following relationships must be guaranteed:

B≥S1+S2+ (20-30mm),B≥100mm,L≥A+B,A takes 8-12mm

In the formula, A represents the stroke of the limit screw; B - Small pull rod stroke: L - Length of the pull rod extending out of the parting surface of the fixed mold; S1 - Length of the main channel; S2 - The length of the split channel. Other precautions are the same as those for the common flow channel two-plate mold.

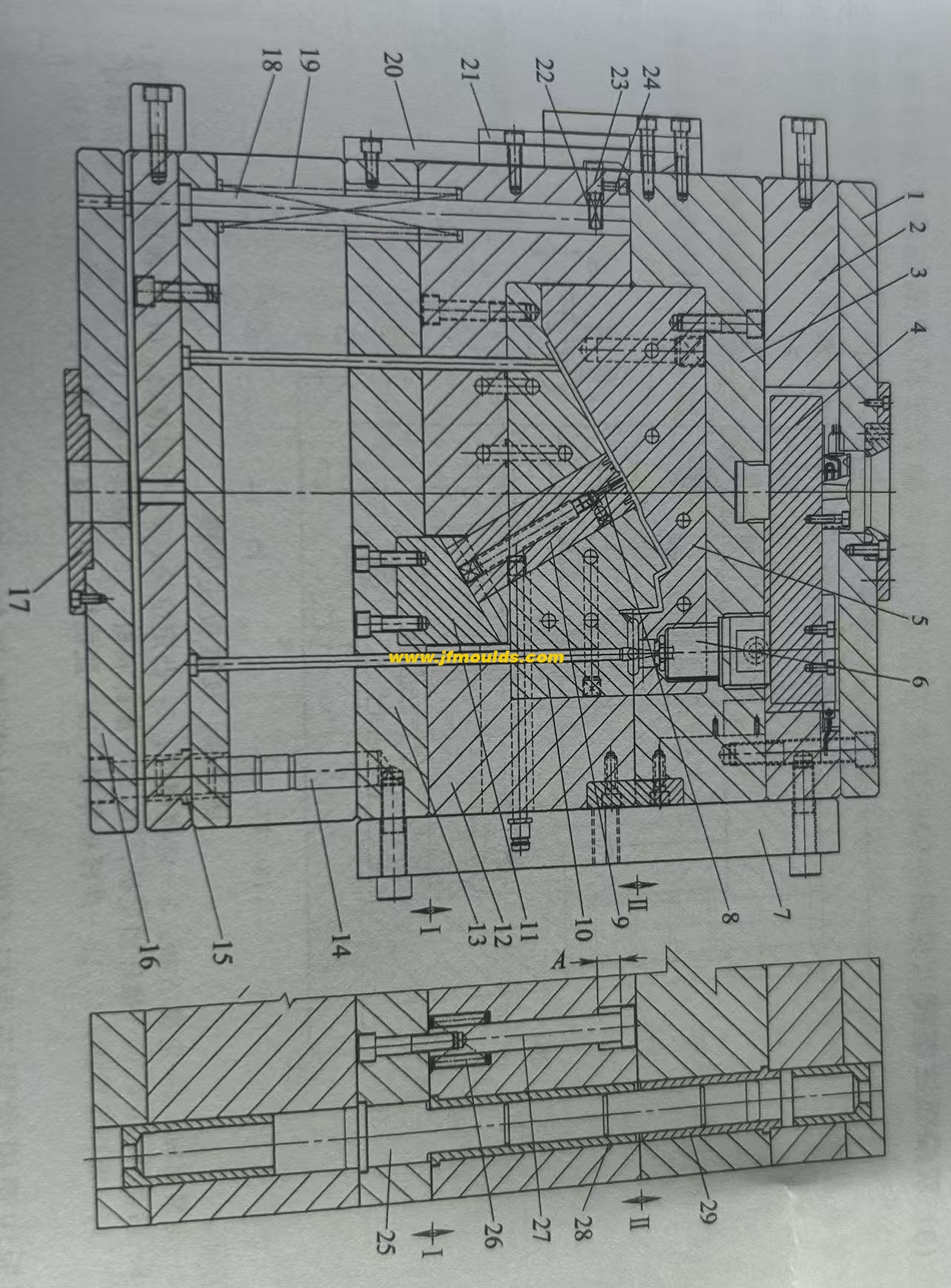

(6) Simplified three-plate mold:

The simplified three-plate mold has four fewer moving mold guide pins than the standard three-plate mold. The fixed mold guide pins must simultaneously push the flow channel plates, guiding both the fixed mold A plate and the moving mold B plate. L≥A+B+20mm. Other precautions are the same as those for the standard three-plate mold. The precision and rigidity of the simplified three-plate mold are inferior to those of the standard three-plate mold, and its service life is also not as good as that of the standard three-plate mold.

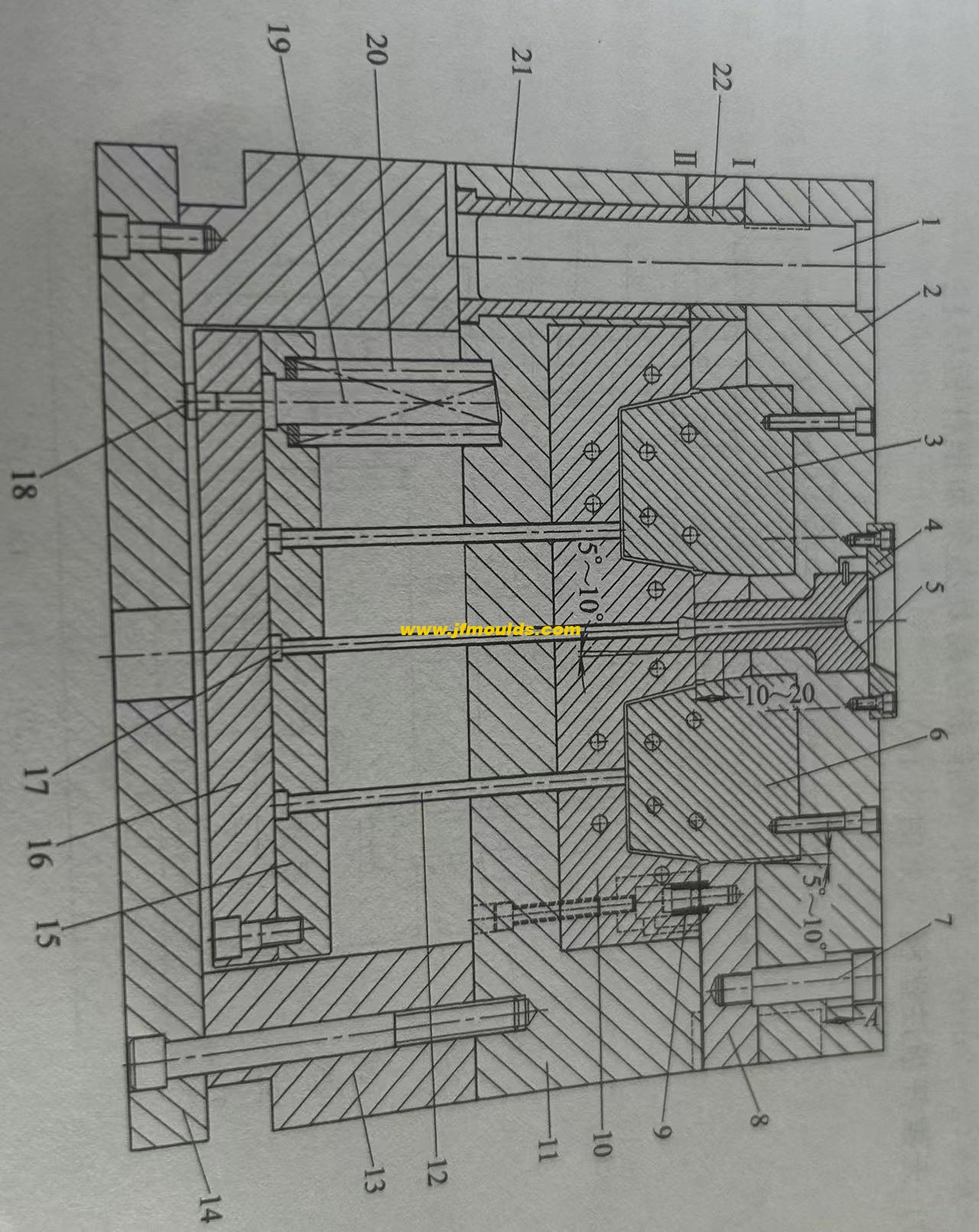

(7) Fake three-board mold:

A false three-board mold is one where the fixed mold part has no open mold surface, while the moving mold part adds one or more open mold surfaces. The mold opening distance A depends on the plastic part. It is often used in situations such as inclined core-pulling of moving molds, secondary demolding and forced demolding.

(8) Second board and half mold

The second half mold is to add a push plate to the fixed mold part. It is used in situations where the fixed mold is pushed out, the fixed mold has a lateral core ejection, or to prevent plastic parts from adhering to the fixed mold core. The mold opening distance A depends on the shape of the plastic part and the depth to which the mold core is tightly wrapped.

Related News

Injection molds: The Cornerstone and Future Trend of Precision Manufacturing

2025-07-12

Injection molds: The Cornerstone and Future Trend of Precision ManufacturingBasi...

Injection molds: From Basic Understanding to Cutting-edge Exploration

2025-07-16

Injection molds: From Basic Understanding to Cutting-edge ExplorationI. Introduc...

Solutions to surface flow patterns, deformation and ejection deformation on both sides of the mold

2025-09-04

Solutions to surface flow patterns, deformation and ejection deformation on both...

The lateral core-pulling mechanism of

2025-10-19

The lateral core-pulling mechanism of "slider inclined guide column"I. Classific...

The solutions for the air marks at the arrow position in the mold direction, the black shadow lines (fusion lines) on the surface, and the trapped air and white spots at the lamp hole position

2025-08-13

The solutions for the air marks at the arrow position in the mold direction, the...

The trapped air adjustment of the mold is difficult, and the deformation and the bottom row position pulling mold treatment method of the face shell

2025-08-12

The trapped air adjustment of the mold is difficult, and the deformation and the...