Causes of defects in injection molded products

Causes of defects in injection molded products

The electrical part of the injection molding machine

The electrical part of an injection molding machine is the power source for its operation. It includes the power supply for the oil pump motor, the electric heating power supply, the drive circuit and the control circuit.

The heating power supply is related to the injection molding temperature parameter. The heating power supply is divided into the main heating circuit and the control circuit. The main heating circuit provides heating for the glue melt cylinder, and the heating ring converts electrical energy into thermal energy. The control circuit provides temperature signal acquisition for the heating circuit and controls the drive execution device to perform electrical energy transmission, that is, to carry out temperature signal acquisition, transmission, operation processing, output drive, high-power electrical energy transmission, etc. Whether the temperature process parameters are set appropriately is an important factor related to the quality of injection molded products. The temperature process parameters are related not only to the plastic raw materials used, but also to the heating temperature of the machine's melt cylinder, the nozzle temperature and the mold temperature. There are various types of plastics with different melting points and densities. Coupled with the mixture of recycled materials and other materials, the temperature setting of the melt cylinder also varies. The heating section Settings of the plastic cylinder in injection molding machines are also different. Therefore, the temperature setting of the melt cylinder should be treated on a case-by-case basis. For commonly used plastic raw materials such as PS, PE, PP, PA, POM, ABS, etc., the temperature parameters should be set in accordance with the technical parameters provided by the supplier. The temperature for heat-sensitive plastics must be strictly set. If the temperature is not set properly, it may cause damage to the product quality or the machine. If the temperature of PVC is not strictly controlled, excessively high temperatures can cause the plastic to decompose or burn, which may affect production or damage the screw or melt cylinder. For heat-sensitive plastics, other factors should be taken into account, such as the frictional heat during the plasticizing process. Generally, the preset temperature should be lower at first, and then raised after the trial injection and adjustment are completed or during the process to prevent decomposition due to excessively high temperatures. The setting and correction of temperature parameters should also be combined with the specific characteristics of plastic raw materials. In addition to considering the size and precision requirements of the mold cavity, the size of the pressure and flow parameters of the injection molding action should also be referred to for comprehensive correction. The common practice is to set the temperature parameters according to the process conditions and adjust other parameters. However, when the plasticizing program is not good, the calibration is not good, or the product is abnormal, it is necessary to verify the setting of the temperature parameters and the actual temperature situation.

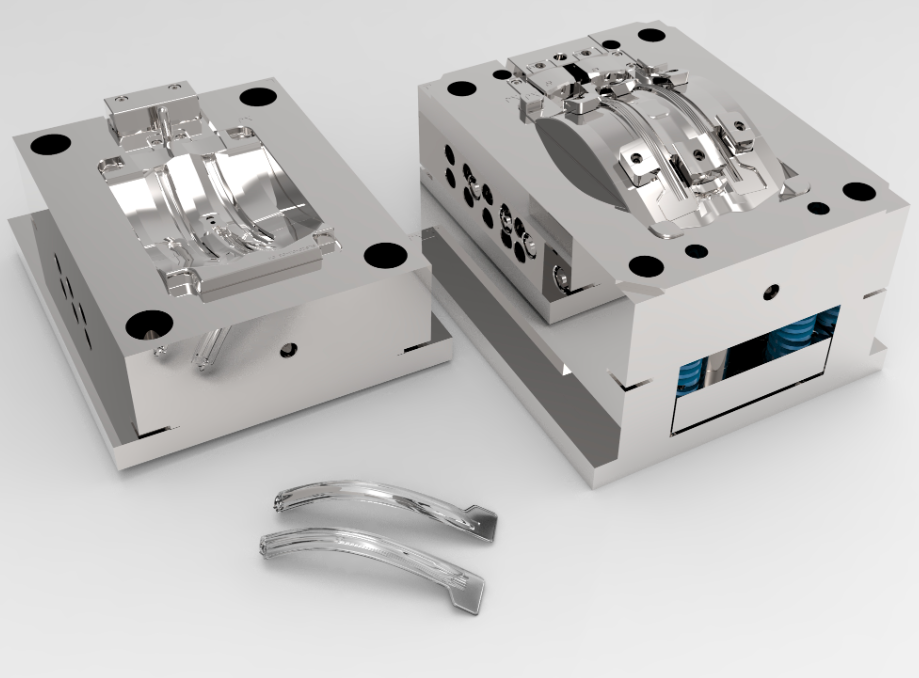

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The temperature parameter Settings should be appropriate. Inappropriate temperature Settings can cause quality problems in injection molded products. Common situations are as follows:

Low heating temperature of the plastic and low mold temperature can cause poor plasticization of the molten plastic compound, which may lead to quality problems of injection molded products. For instance, insufficient injection of the injection part, rough surface, poor transparency, poor welding of plastic products, surface flow lines and ripples, cold blocks or hard materials, electrical delamination and peeling of mica, brittle products, etc.

Low mold temperature can lead to adverse defects such as rough product surface, brittle cracking of the product, and layered gates.

Car Lamp Mold Manufacturer in China (jfmoulds.com)

2. Mechanical transmission part of the injection molding machine

The mechanical transmission part of an injection molding machine is the framework and actuator of the injection molding machine. The mechanical transmission system is composed of the clamping part, the injection part and the auxiliary part, and the system completes each action of injection molding through the hydraulic drive device. The operation of mechanical mechanisms is the quality guarantee of injection molded products

Imbalance of the template can cause a gap between the moving mold and the static mold, resulting in flash defects in the injection molded products. The reason is that there is a fit clearance between the screw in the injection part and the melt cylinder. Under normal circumstances, plastic raw materials are plasticized into molten rubber compound under the heating conditions of the heating ring. During injection, the molten rubber compound is pushed into the mold cavity through the injection nozzle. If the gap between the screw and the melt barrel is too large and severely worn, complete plasticization cannot be achieved, which will affect the product quality. If the screw's glue passing head or glue passing medium is damaged, it will cause weak glue injection or glue leakage.

The clamping part mainly consists of the clamping body formed by the template and the pull rod (Corinth column). Support the opening and closing actions of the moving formwork. The parallelism between the Corinth columns, the perpendicularity between the template and the frame, and the coaxiality of the nozzle and the template pouring port are all related to the quality of injection molded products. Improper fit of the mechanical transmission mechanism of the injection molding machine, lubrication failure, etc., can all cause wear or premature failure of the machine. If the calibration is improper, it will cause machine wear or significant vibration, which will seriously affect the service life of the products or the machine.

Molds also frequently malfunction during the production process, affecting product quality, such as mold scratches and mold pulling. Glue inlet position drag damage: Water inlet deformation, drag damage, adjacent position; Faults related to the mechanical aspects of the mold, such as bone position drag damage, bone position deformation, and buckle position overturning. In the actual production process, all need to be controlled and handled.

2.3 Hydraulic System of Injection Molding Machine

The hydraulic system of an injection molding machine is driven by the electrical control system and drives the mechanical transmission part through the hydraulic transmission system. It can also be said to be the power source for each action in injection molding. It relies on hydraulic actuating elements to drive the mechanical transmission system to work, converting hydraulic energy into mechanical energy. The hydraulic transmission system mainly takes the power element oil pump as the core component. It drives the actuator to move through control components (various flow, pressure and directional valves), and the oil motor drives the screw to rotate to plasticize the plastic. The auxiliary components of the hydraulic system serve the hydraulic transmission system. The hydraulic system also provides functions such as oil storage, filtration, heat dissipation, impurity sedimentation, cooling of pressure oil and display of pressure values. Every part of the hydraulic system is closely related to injection-molded products, mechanical transmission and electrical control. Therefore, the hydraulic transmission system is an indispensable and important component in injection molding production.

The oil pump is the core component that provides pressure for the hydraulic system and also serves as the pressure source for the system. It directly affects the reliable and stable performance of each action in injection molding and the quality of injection molded products. The oil pump, in conjunction with the pressure valve and flow valve, provides the power required for mechanical transmission in the system, while the directional valve offers the corresponding mechanical transmission for the sequential control and timing control of the system. When adjusting products and checking for faults, it is generally carried out under the condition that the hydraulic system is normal. Therefore, when adjusting products cannot eliminate defects, the hydraulic system should be inspected and adjusted. Mechanical actions and hydraulic drives related to injection molding are also key points of the inquiry.

2.4 Injection Molding Process Parameters

As mentioned earlier, the setting of injection molding process parameters directly affects the quality of injection molded products. During the injection molding operation, each process parameter is closely related to the quality of the product. The mutual coordination, complementarity, good configuration, and optimal combination of process parameters are the technical and quality guarantees for forming high-quality products. Among the process parameters, the pressure parameters mainly involve incident glue pressure, holding pressure, mold locking pressure, etc. The speed parameters mainly involve injection speed, mold lifting speed, mold locking speed and injection speed, etc. The time parameters mainly involve injection time, cooling time, low-pressure mold locking time and cycle time, etc. The position and stroke parameters mainly involve the stroke transformation during the opening and closing of the mold, the stroke position control during the injection process, and the stroke setting during the melting process, etc. The temperature parameters mainly involve the heating temperature of various plastics, the heating temperature of each heating section, the heating temperature of the injection nozzle, the mold temperature and the oil temperature control, and other parameter Settings. All these parameter Settings should be made in accordance with the technical conditions of the injection molding process of the injection molding machine itself. In the specific operation process, it is also necessary to combine the actual situation, based on the composition of the plastic raw materials, the plasticizing condition of the machine's melt cylinder, and in combination with work experience, to revise or modify it. The operation also needs to be calibrated through trial operation.

By addressing the defects of the formed products, targeted parameter adjustments should be made. Only after the qualified formed products are obtained through supplementary modifications can the injection molding machine operate normally. The setting of process technology parameters should be appropriate and in line with process technology requirements. When adjusting parameters, strict operation must be carried out and the process flow rules must be followed. During the calibration and trial operation, the following Settings should be avoided: the pressure parameter is set very low while the flow parameter is set very high; The holding pressure parameter is set very high while the flow parameter is set very low.

Common issues regarding the setting of pressure parameters and speed parameters are as follows:

(1)Insufficient setting of pressure parameters or speed parameters can lead to dents and bubbles on the products. The surface of the product has ripples, poor welding and obvious welding marks. The surface of the product is swollen, with flow lines and ripples. The product is brittle and the gate is layered and has other defects.

(2)If the pressure parameter or speed parameter is set too high, it will cause defects such as discoloration, black spots and black lines on the product.

(3) Excessively high pressure parameter Settings can lead to defects such as material edge overflow, excessive flash, glue leakage, mold sticking, poor demolding, and product cracking or cracking in the formed products.

(4)Setting the speed parameter too high leads to defects such as charring of the formed products, poor transparency, and poor quality of plastic parts.

(5)If the pressure parameter is set too low, it will lead to defects such as insufficient injection of the product, incomplete filling of the mold cavity, unstable dimensions, silver streaks or patterns, and rough product surface.

The speed parameter setting is too low, resulting in defects such as rough surface and easy warping and deformation of the product.

Common time parameter setting issues are as follows:

If the injection time is set too short, it will lead to insufficient injection of the product or incomplete filling of the mold cavity, dents or bubbles, silver streaks or spots, unstable product dimensions, brittle products, and poor plastic parts, etc.

If the injection time is set too long, it will lead to defects such as edge overflow, glue leakage, mold sticking or gate blockage in the formed products, layered gate appearance and poor demolding.

If the cooling time is set too long, it will cause defects such as sticking to the gate and cracks in the formed products.

If the cooling time is set too short, it will cause defects such as warping and deformation of the product, unstable product dimensions, clogging of the sprue or sticking of the gate to the mold, and fragility of the plastic part.

If the holding time is set too short, it will lead to defects such as unstable dimensions of the injection molded products, silver streaks or patterns on the products, dents or bubbles on the products, and brittleness of the products.

Related News

Surface roughness of mold-formed parts

2025-10-13

Surface roughness of mold-formed partsI. Representation Methods and Meanings of ...

Common defects of Injection molded products and their solutions

2025-07-29

Common defects of Injection molded products and their solutions The diagnosis...

The positioning ring and screws of the mold

2025-10-07

The positioning ring and screws of the moldOne: Positioning circleThere are two ...

The "Shaping Master" Hidden in Daily Necessities

2025-07-17

The "Shaping Master" Hidden in Daily Necessities In today's industrial produc...

The demolding types of two-plate molds

2025-07-22

The demolding types of two-plate molds1.1 Injection-molded parts without overhan...

Diversification of injection mold enterprises

2025-06-28

Diversification of injection mold enterprises1. Automotive Molds: Driving Indust...