The "Shaping Master" Hidden in Daily Necessities

The "Shaping Master" Hidden in Daily Necessities

In today's industrial production, injection molds play a crucial role and can be regarded as one of the cornerstones of modern industry. It is like a magical "magician", capable of precisely shaping various plastic raw materials into plastic products of all shapes and functions needed in our daily life and industrial fields. From the delicate and exquisite shells of electronic components to the large and complex parts of automobiles, injection molds are everywhere, and their significance is self-evident. With the rapid development of technology and the continuous improvement of industrial demands, injection mold technology is also constantly innovating and transforming, demonstrating strong vitality and development potential.

I. Working Principle of Injection Molds

The working principle of injection molds is based on the thermoplastic properties of plastics. In simple terms, it involves feeding granular plastic raw materials into a heated barrel through the hopper of an injection molding machine. Inside the barrel, the plastic raw materials are heated to a molten state. At this point, the screw of the injection molding machine rotates under the drive of the motor, pushing the molten plastic forward. Under a certain pressure, it is injected at high speed into the cavity of the mold. The shape of the mold cavity is exactly the same as the plastic product we ultimately want to obtain. When the plastic fills the cavity, after a period of pressure holding and cooling, the plastic gradually solidifies and takes shape. Finally, the formed plastic product is smoothly pushed out through the demolding mechanism of the mold, completing one injection molding process.

Ii. Application Fields of Injection Molds

Injection molds, with their production features of high efficiency, high precision and high consistency, have been widely applied in numerous fields, almost covering all aspects of our lives.

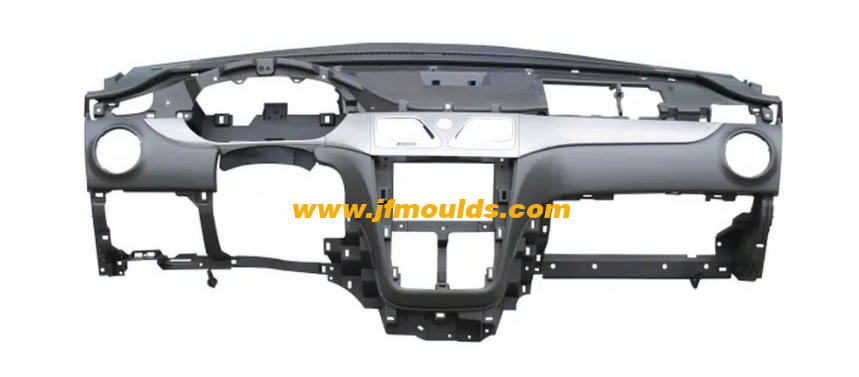

1. Automotive industry: The automotive industry is one of the important application fields of injection molds. In the manufacturing process of automobiles, a large number of components are produced by injection molds, such as interior parts (instrument panels, door panels, seats, armrests, etc.), exterior parts (bumpers, lamp covers, rearview mirror housings, etc.), engine peripheral parts (intake manifolds, radiator frames, filter housings, etc.) and various functional parts (plastic gears, clips, seals, etc.). These injection-molded parts not only meet the requirements of automobiles for lightweight, aesthetics and functionality, but also can be mass-produced, reducing production costs and enhancing the market competitiveness of automobiles.

Automobile dashboard mold Manufacturer in China (jfmoulds.com)

2. Electronic and electrical industry: In the field of electronic and electrical appliances, injection molds also play an indispensable role. From the consumer electronic products we use daily such as mobile phones, computers, tablets and televisions, to various industrial electronic devices, many of their shells and components are manufactured through injection molds. For instance, mobile phone casings need to have features such as being thin, light, sturdy and aesthetically pleasing. Injection molds can produce mobile phone casings that meet these requirements through precise design and processing. All kinds of plastic components inside a computer, such as fan blades, heat sinks, and case frames, also rely on the efficient production of injection molds. The application of injection molds enables electronic and electrical products to achieve miniaturization, lightweight and high performance, while also improving production efficiency and reducing product costs.

3. Home appliance industry: The home appliance industry is also an important application scenario for injection molds. The shells, inner linings, control panels and components of various household appliances such as refrigerators, washing machines, air conditioners, microwave ovens and rice cookers are mostly made by injection molding process. Injection molds can produce plastic components of various shapes and functions according to the design requirements of different household appliances, meeting the demands of household appliances for good appearance, reasonable structure and reliable performance. Moreover, through the large-scale production of injection molds, the manufacturing cost of household appliances can be effectively reduced, making them more popular and accessible to the public.

4. Medical device industry: With the continuous advancement of medical technology and the increasing emphasis on health by people, the demand for injection molds in the medical device industry is also growing day by day. Many medical device products, such as syringes, infusion sets, catheters, surgical instruments, dentures, and medical equipment shells, are produced using injection molds. The application of injection molds in the manufacturing of medical devices not only ensures the high precision and consistency of the products, meeting the strict requirements of medical devices for quality and safety, but also enables large-scale production, improves production efficiency, reduces medical costs, and provides more high-quality and convenient medical services for a large number of patients.

5. Packaging industry: The packaging industry is one of the fields where injection molds are most widely applied. All kinds of plastic packaging products, such as plastic bottles, plastic boxes, plastic buckets, plastic films, plastic pallets, etc., are all produced through injection molds. Injection molds can be designed and manufactured in various shapes, sizes and structures according to the packaging requirements of different products, achieving the diversification and personalization of packaged products. Moreover, injection-molded plastic packaging products have the advantages of light weight, high strength, good sealing performance, corrosion resistance, and easy processing. They can effectively protect products, extend their shelf life, and are also convenient for transportation and storage. In addition, injection molds can also achieve functions such as anti-counterfeiting, anti-theft and environmental protection for packaged products through some special designs and processes, meeting the higher requirements of the market for packaged products.

6. Toy and Stationery industry: In the field of toys and stationery, the application of injection molds is also very common. All kinds of plastic toys (plastic building blocks, dolls, toy cars, educational toys, etc.), stationery (plastic pens, pencil cases, file folders, rulers, etc.), sports goods (plastic rackets, sports protective gear, fitness equipment parts, etc.) are all masterpieces of injection molds. Injection molds can produce brightly colored, lifelike, safe and non-toxic toys and cultural and sports goods, meeting the demands of children and consumers for the fun, practicality and safety of products. Meanwhile, the efficient production capacity of injection molds also enables toys and cultural and sports goods to be mass-produced, reducing costs and enriching market supply.

Spoon mold Manufacturer in China (jfmoulds.com)

Iii. Design and Manufacture of Injection Molds

(1) Design Process and Key Points

The design of injection molds is a complex and rigorous process, which requires comprehensive consideration of multiple factors such as the shape, size, precision, performance requirements, production batch, and injection molding process of plastic products. Generally speaking, the design process of injection molds mainly includes the following steps:

1. Process analysis of plastic products: Before designing the mold, a comprehensive process analysis of the plastic products must be conducted first. This includes understanding the uses, structural features, dimensional accuracy requirements, surface quality requirements of plastic products, as well as the performance of plastic materials, etc. Through the analysis of these factors, the molding process plan for plastic products is determined, such as the selection of injection molding machines, the setting of injection molding process parameters, the selection of mold parting surfaces, the design of gating systems, and the determination of demolding methods, etc. At the same time, it is also necessary to conduct demolding analysis, wall thickness analysis, and reinforcing rib design on plastic products to ensure that they can be smoothly demolded during the molding process and avoid defects such as shrinkage marks, deformation, and bubbles.

2. Mold structure design: Based on the process analysis results of plastic products, the mold structure is designed. This is the core link in injection mold design, which requires designers to have rich experience and professional knowledge. During the mold structure design process, it is necessary to determine the overall structural form of the mold, such as two-plate molds, three-plate molds, hot runner molds, etc. Design each component of the mold, including the forming parts, gating system, guiding and positioning mechanism, demolding mechanism, lateral core-pulling mechanism, temperature regulation system, etc. Draw the two-dimensional engineering drawings and three-dimensional models of the mold, and mark in detail the technical requirements such as the dimensions, tolerances, surface roughness and materials of each component. During the design process, it is also necessary to fully consider factors such as the processability of the mold, the convenience of assembly and debugging, and its service life, to ensure that the designed mold can meet production requirements and has good economy and reliability.

3. Optimization and Verification of mold design: After completing the mold structure design, it is necessary to optimize and verify the design plan. This can be simulated and analyzed through some professional mold design software, such as CAD (Computer Aided Design), CAE (Computer Aided Engineering), etc. The CAD software can be used to conduct detailed design and modification of the mold structure, check the interference between each part of the mold, and optimize the layout and size of the mold. CAE software can be used to simulate and analyze the injection molding process, predict possible defects of plastic products during the molding process, such as weld lines, cavitation, warpage deformation, etc., and solve them by adjusting injection molding process parameters or mold structure design. Through optimization and verification, the quality and reliability of mold design can be enhanced, the number of mold trials can be reduced, production costs can be lowered, and the product development cycle can be shortened.

(II) Manufacturing Processes and Technologies

The manufacturing process and technology of injection molds directly affect the quality, precision and service life of the molds. With the continuous development of the manufacturing industry, the manufacturing process of injection molds is also constantly innovating and improving, and many advanced manufacturing technologies have emerged.

1. Traditional processing techniques

The traditional injection mold processing techniques mainly include mechanical processing, electrical discharge machining, wire cutting processing, etc. Mechanical processing is the most fundamental processing method. Through machine tools such as lathes, milling machines, planers, grinders and drills, the mold materials are cut and processed to manufacture various components of the mold. Mechanical processing has the advantages of high processing accuracy, good surface quality and wide processing range. However, for some complex-shaped mold parts, the processing difficulty is relatively high and the efficiency is low. Electrical discharge machining (EDM) uses the high temperature generated by discharge to erode away the mold material, thereby achieving the processing purpose. Electrical discharge machining is suitable for processing various complex-shaped mold cavities, cores, and some parts that are difficult to process by mechanical methods, such as narrow slits, small holes, and irregular curved surfaces. It has the advantages of high processing accuracy and the ability to process any conductive materials, but the processing speed is relatively slow and the cost is relatively high. Wire cutting (WEDM) is a process that uses a moving fine metal wire (electrode wire) as a tool electrode to cut mold materials through pulsed discharge. Wire cutting processing is mainly used for processing type holes, irregular holes, narrow slots, etc. in molds. It has the advantages of high processing accuracy, good surface roughness, and no need for cutting tools during the processing. It can process some complex shapes that are difficult to achieve by other processing methods.

2. Numerical Control machining technology

Numerical control machining technology is one of the most widely used advanced processing technologies in modern manufacturing and also plays an important role in injection mold manufacturing. Numerical control machining refers to the automatic processing of mold components by controlling the movement of machine tools and the processing process through a computer control system in accordance with pre-programmed procedures. Numerical control machining technology has the advantages of high processing accuracy, high processing efficiency, stable processing quality, and the ability to process complex shapes. In injection mold manufacturing, commonly used CNC processing equipment includes CNC milling machines, CNC machining centers, CNC electrical discharge machining machines, CNC wire cutting machines, etc. By using numerical control machining technology, high-precision processing of mold components can be achieved, reducing the influence of human factors on processing quality and improving the manufacturing accuracy and production efficiency of molds.

3. High-speed cutting technology

High-speed cutting technology is an advanced cutting processing technology. It adopts a cutting method with high rotational speed, high feed rate and small cutting depth to perform high-speed cutting processing on mold materials. High-speed cutting technology has the advantages of high processing efficiency, high processing accuracy, good surface quality and long tool life. In the manufacturing of injection molds, high-speed cutting technology can be applied to process components such as the cavity, core, and inserts of the mold, which can significantly reduce processing time and enhance the manufacturing efficiency of the mold. Meanwhile, the surface quality of the mold after high-speed cutting processing is high, which can reduce the subsequent polishing processing procedures and lower the production cost. In addition, high-speed cutting technology can also process some high-hardness mold materials that are difficult to process by traditional processing methods, thus broadening the range of mold material selection.

4. Mold surface treatment technology:

Mold surface treatment technology is one of the important means to improve the performance and service life of injection molds. By treating the surface of the mold, the hardness, wear resistance, corrosion resistance, demolding property and other properties of the mold surface can be improved, thereby enhancing the working efficiency and service life of the mold. Common surface treatment techniques for molds include nitriding treatment, hard chromium plating treatment, PVD (Physical Vapor Deposition) coating treatment, and CVD (Chemical Vapor Deposition) coating treatment, etc. Nitriding treatment involves penetrating nitrogen atoms into the surface of the mold to form a nitrided layer with high hardness and good wear resistance, thereby enhancing the hardness and wear resistance of the mold surface. Hard chromium plating treatment involves coating a layer of hard chromium on the surface of the mold, which endows the mold surface with excellent wear resistance, corrosion resistance and demolding property. PVD coating treatment and CVD coating treatment involve depositing a high-performance coating layer on the mold surface through physical or chemical methods, such as TiN (titanium nitride) coating, TiC (titanium carbide) coating, etc. These coatings have the advantages of high hardness, good wear resistance, and strong chemical stability, which can significantly improve the performance and service life of the mold.

5. Rapid mold-making technology

Rapid mold-making technology is a new type of mold manufacturing technology that has developed in recent years. It can produce injection molds quickly and at low cost. Rapid mold making technology mainly includes rapid mold making methods based on rapid prototyping technology and direct metal laser sintering (DMLS) rapid mold making technology, etc. The rapid mold-making method based on rapid prototyping technology is to first manufacture the prototype of the mold by using rapid prototyping technology (such as 3D printing technology), and then obtain the injection mold by replicating or converting the prototype. This method has the advantages of short mold-making cycle, low cost and the ability to respond quickly to market demands. It is suitable for the production of small-batch and multi-variety plastic products. The direct metal laser sintering rapid mold-making technology uses a high-energy laser beam to sinter metal powder layer by layer, directly manufacturing injection molds. This method can produce molds with complex structures and high performance, eliminating the need for traditional mold processing techniques. It significantly shortens the mold manufacturing cycle and enhances the manufacturing accuracy and quality of the molds.

Related News

The structure, materials and design of injection molds

2025-07-18

The structure, materials and design of injection molds In the vast landscape ...

The glue inlet position of the mold is dragged and charred

2025-08-06

The glue inlet position of the mold is dragged and charredThe glue inlet of the ...

The causes and solutions of silver streaks, discoloration, surface ripples and roughness in injection molded products

2025-07-30

The causes and solutions of silver streaks, discoloration, surface ripples and r...

Standard parts of molds

2025-07-24

Standard parts of molds1 Mold framePrefabricated standard mold base assemblies o...

The causes and solutions of dents on injection molded products, incomplete finished products, and flash on products

2025-07-29

The causes and solutions of dents on injection molded products, incomplete finis...

Multiple mold designs

2025-07-25

Multiple mold designsIn-mold labeling processThin-walled plastic packaging produ...