The demolding types of two-plate molds

The demolding types of two-plate molds

1.1 Injection-molded parts without overhangs

A non-inverted injection-molded part means that the component has no obstructions and can be easily pushed out during demolding.

In the field of plastic processing, many product applications fall within the category of "no-upside-down products". Non-inverted demolding is almost applicable to all molds except three-board molds. Molds without inverted parts belong to relatively simple "opening and closing" molds and do not require additional moving parts.

To ensure a simple and safe separation, the glue inlet should be made in a conical shape, with a designed taper of 3° being ideal. Typical applications include injection-molded parts that can be separated and ejected without the need to increase the parting surface or lateral movement. This type of product includes cups, LIDS, covers, door handles and clothes hangers.

2.2 Injection molded parts with upturned parts

2.2.1 Elastic discharge

The definition of elastic demolding refers to the simple demolding of injection-molded parts without the action of a slider during mold opening. To achieve more elastic demolding, the raw materials must be tough and elastic. The ideal raw materials include polypropylene (PP), polyvinyl chloride (PE), soft polyvinyl chloride (PVC), or elastomers.

Demolding is usually accomplished by what is called demolding, but it can also be done using ejector pins, ejector pins or air ejector pins. Injection molded parts usually do not require other ejection components.

Application scope

The most common application is the manufacturing of threaded bottle caps. There are also many applications in the medical and packaging fields.

Water ladle mold Manufacturer in China (jfmoulds.com)

2.2.2 Slider demolding

The inverted part refers to the concave or raised area on the injection molded part, which increases the difficulty of demolding and, in extreme cases, even prevents demolding. At this point, a slider is needed to increase the auxiliary parting surface to separate the product with an inverted part in the demolding direction.

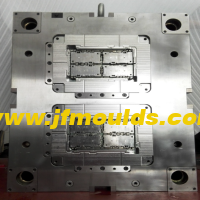

Cold runner slider mold

The sliders installed on the fixed mold side or the moving mold side can move perpendicularly to the mold opening direction. When the mold is opened, the slider slides to one side at a 90° Angle to the mold's axis. The maximum angular deviation between the two directions must not exceed the actual value; otherwise, the slider will self-lock.

The slider demolding is mechanically accomplished by an inclined guide column or control rod, also known as forward control.

The movement of the slider is accomplished by mechanical structures, springs, pneumatic cylinders or hydraulic cylinders before, after or during the mold opening process.

Typical products for slider applications include power boards, winding frames, wire clamps, pins and external thread parts.

2.2.3 Block demolding

In a block mold, two or more blocks completely enclose the injection molded part, while in a slider mold, only part of the injection molded part is separated.

In a slider mold, the mold cavity is usually a single part. In the block mold, the mold cavity is composed of several blocks. The blocks can be diagonally embedded on one side of the fixed mold and slide outward along the diagonal grooves when the mold is opened. In this way, the injection-molded parts can be demolded.

Similarly, the blocks can also be guided from the top exit side like sliders. Most of them are driven to slide by hydraulic cylinders, mechanical springs or air pressure during or after mold opening.

Any size of the block needs to be connected to the cooling water circuit of the mold.

The block mold can integrate all known runner systems and pouring variations. The injection molding and the injection molded part are on the same parting surface and need to be separated after injection molding.

A typical application of block molds is bottle frames and car battery boxes.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

2.2.4 Telescopic core demolding

In addition to threads, for some other products with inverted threads, telescopic cores can be used for demolding. These products include anti-counterfeiting rings on bottle caps, pull rings and other similar structured products.

When using telescopic cores, it is necessary to ensure the correlation between the depth and diameter of the thread. When the thread diameter is 28mm, the depth should be 0.8 to 1.0mm. Therefore, threads with a diameter of 28mm and a depth of 3mm cannot be produced by telescopic cores, but they can be produced by rotating cores.

The interrelationship between the depth and diameter of this thread is formed in this way: after the central core is drawn out, the surrounding blocks can only contract inward to the position where they interlock.

It is mainly applied to products on injection-molded parts where threaded or quasi-threaded upturns only play a minor role, such as container LIDS that can be repeatedly closed.

Related News

The drawing of the mold and the inking of the gate

2025-08-05

The drawing of the mold and the inking of the gateMold drawing Phenomenon: Th...

Methods for the easy breakage of the internal position of the mold and the easy damage of the screw column during the mold opening process

2025-08-07

Methods for the easy breakage of the internal position of the mold and the easy ...

From custom development to global supply, unlock the core driving force of modern manufacturing

2025-07-19

From custom development to global supply, unlock the core driving force of moder...

Causes of defects in injection molded products

2025-07-27

Causes of defects in injection molded products The electrical part of the inj...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

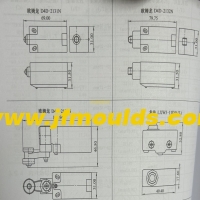

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...