Diversification of injection mold enterprises

Diversification of injection mold enterprises

1. Automotive Molds: Driving Industrial Innovation with Ultimate Precision

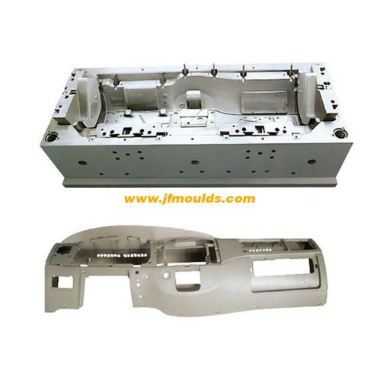

As a benchmark field of manufacturing, the automotive industry has extremely strict requirements for the precision, strength and stability of components. Injection mold enterprises have been continuously delving into the field of automotive mold manufacturing, meeting the industry's high standards with leading processes and technologies.

Automotive exterior mold is also facing huge challenges.

Components such as bumpers and lamp housings not only need to have an outstanding appearance but also meet performance requirements such as weather resistance and impact resistance.

With the help of mold flow analysis software (CAE), mold enterprises can simulate the flow and cooling process of plastics in advance, precisely optimize the gate position and cooling waterway design, effectively avoid defects such as weld marks and warping deformation, and significantly improve the molding quality of exterior parts.

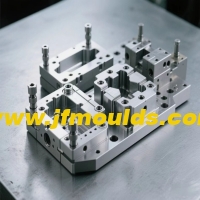

Car plate molds and automotive plastic parts molds

2. Motorcycle Molds: A Perfect Blend of Performance and Individuality

Motorcycles possess both practicality and personalization features. The manufacturing of their molds needs to ensure performance while fully demonstrating a unique design style.Injection mold enterprises are deeply involved in the development of motorcycle molds, closely collaborating with vehicle manufacturers to transform creative designs into high-quality mold products.

In the manufacturing of body panel molds, enterprises must not only ensure the strength and rigidity of the components to provide a solid guarantee for riding safety, but also endow motorcycles with a dynamic and fashionable appearance through complex curved surface designs.The application of five-axis linkage processing technology enables mold enterprises to produce high-precision complex curved surface molds, making the surface of the covering parts smooth and flowing with natural lines.During the mold design process of fuel tanks, seats, etc., the enterprise fully considers the principles of ergonomics. Through precise size control and meticulous surface treatment processes, it significantly enhances the comfort of riding.In response to the growing demand for personalized customization in the motorcycle market, mold enterprises have adopted rapid mold changing technology and modular design, shortening the new product development cycle by more than 30% and providing customers with a rich variety of choices.

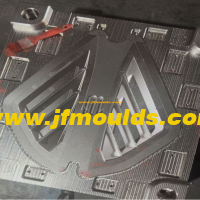

Motorcycle plastic parts mold

Motorcycle plastic mold Manufacturer in China (jfmoulds.com)

3. Daily Necessities Molds: Dual-Driven by Efficient Production and Quality Upgrading

Daily necessities are closely related to People's Daily lives and have a huge market demand, which puts forward higher requirements for the production efficiency and cost control of molds.Injection mold enterprises have achieved efficient and stable mass production by optimizing mold structures and innovating production processes.

In the mold design of daily necessities such as plastic tableware and storage boxes, the wide application of multi-cavity mold structures enables multiple products to be formed in one injection molding, increasing production efficiency several times over.Meanwhile, by rationally designing the gating system and cooling system, enterprises have shortened the product molding cycle by 20% to 30%, effectively reducing production costs.Under the premise of ensuring production efficiency, mold enterprises attach great importance to product quality.For molds of daily necessities that come into contact with food, mold materials that meet food hygiene standards are strictly selected, and fine surface treatment is carried out to ensure that the products are non-toxic, harmless and easy to clean.In addition, enterprises are constantly innovating and developing molds for daily necessities with special functions, such as molds for kitchenware with anti-slip textures and molds for food storage containers with self-sealing structures, bringing more convenience and quality improvement to people's lives.

Chair and table molds

4. two-color mold: innovative process to create differentiated products

the two-color mold realizes the fusion of two colors or materials through one injection molding, which becomes the key technology to enhance the added value of products. Injection mold companies continue to break through technical bottlenecks in this field.

The two-color injection mold independently developed by the enterprise adopts double nozzles.+ rotary mold core structure, through the servo motor control mold rotation accuracy.± 0.01 ° to ensure that the two materials are accurately connected. In the production of electronic equipment enclosures, through soft and hard glue co-injection technology, PC hard outer layer and TPU the soft inner layer is combined to ensure the structural strength and improve the grip. In the field of toy manufacturing, the two-color mold realizes the one-time molding of gradient color and pattern texture, which improves the visual effect of the product significantly.

In order to optimize process stability, the company has established a two-color injection molding process database through AI the algorithm intelligently matches parameters such as material temperature and injection pressure, and shortens the debugging time.40%, the yield increased95% above.

Related News

Solutions to problems such as poor transparency, unstable dimensions, spots, and black lines in injection molded products

2025-07-31

Solutions to problems such as poor transparency, unstable dimensions, spots, and...

Types and basic requirements of mold design drawings

2025-09-07

Types and basic requirements of mold design drawingsTo shorten the production cy...

Surface roughness of mold-formed parts

2025-10-13

Surface roughness of mold-formed partsI. Representation Methods and Meanings of ...

The grooves of the mold's injection air inlet, the surface light and shadow, the scratches on the grooves and the size of the screw holes have increased

2025-08-13

The grooves of the mold's injection air inlet, the surface light and shadow, the...

Multiple mold designs

2025-07-25

Multiple mold designsIn-mold labeling processThin-walled plastic packaging produ...

From principle to application, understand this "shaping master" in industry

2025-07-16

From principle to application, understand this "shaping master" in industry P...