The setting of injection molding temperature and time parameters

The setting of injection molding temperature and time parameters

1. Setting of temperature parameters

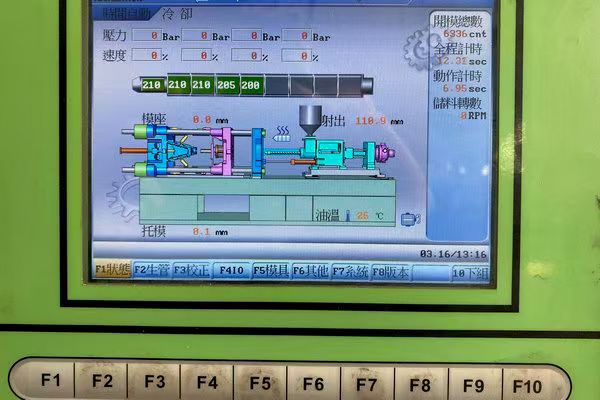

Injection molding temperature parameters are the core content of the injection molding process, directly related to the quality of injection molded products and influencing the time parameter Settings of plasticizing flow and each process of the molded products. The general temperature parameters mainly include the heating temperatures of each area of the melt glue cylinder, the nozzle temperature, the mold temperature, the material temperature, and the oil temperature, etc.

(1) Temperature parameters of the glue melt cylinder

Injection molding is the process of heating plastic to evenly plasticize granular raw materials into molten rubber in a molten rubber cylinder, ensuring that the molten rubber can be smoothly filled into the mold. The temperature of the melt glue cylinder usually gradually rises from the hopper opening to the nozzle because the plastic is gradually plasticized inside the melt glue cylinder. The frictional heat generated by the shearing action in the screw groove and other factors all directly affect the temperature, so the temperature parameter setting is carried out in sections. Usually, the melt glue cylinder is divided into the front end, middle section and rear end heating zones, and the required parameters are set respectively. The temperature of the molten rubber compound is generally higher than the flow temperature of the plastic and the melting point of the plastic, but lower than the decomposition temperature of the plastic. In actual production, it is often determined based on experience or according to the situation of injection molded products. If the temperature requirement for engineering plastics is higher, the temperature of the melt cylinder can be set slightly higher to ensure the plastic is fully plasticized.

(2) Setting of nozzle temperature parameters

The nozzle is the hub that connects the mold type control gate, runner port and pouring port inside the melt glue cylinder. The nozzle temperature is set reasonably, ensuring melting

The flow performance of the rubber compound is appropriate, making it easy to fill the mold. At the same time, the properties of plastic products, such as welding strength and surface gloss, can be improved. If the temperature of the nozzle is too low, cold material may clog the nozzle or the gates and runner ports of the gating system, preventing normal and smooth production. Moreover, cold material may cause cold material spots on the products, affecting the quality of plastic products. If the nozzle temperature is too high, it will cause the molten rubber compound to overheat and decompose, resulting in a decline in the physical and mechanical properties of plastic products, etc. The temperature setting of the nozzle is generally carried out to fully maintain a constant nozzle temperature.

(3) Setting of mold temperature parameters

Mold temperature generally refers to the temperature of the contact surface between the inner wall of the mold cavity and the plastic product. Mold temperature adds to precision injection molding The appearance quality and performance of industrial plastic products have a significant impact. The setting of mold temperature parameters is often determined by the size and structure of the plastic part product, the characteristics of the plastic material, and the process conditions of the plastic product. The setting of mold temperature is all about cooling for the molten rubber compound. Controlling the mold temperature can enable the plastic molded products to cool and form, providing conditions for smooth demolding. Controlling the mold temperature can ensure that the temperature of all parts of the mold cavity is balanced and consistent, and the heat dissipation degree of the products inside the cavity is consistent, so as to avoid the decline of product performance caused by the generation of internal stress and guarantee the quality of the products.

(4) Material temperature and oil temperature

Plastic raw materials need to be treated before injection molding because they will absorb moisture from the atmosphere during storage and transportation. The moisture content of some macromolecular raw materials containing hydrophilic genes, such as nylon, may far exceed the range allowed by the injection molding processing of the material. The saturated water absorption rate of polycarbonate can reach 0.2% to 0.5%, that of nylon PA6 can reach 1.3% to 1.9%, and that of ABS can reach 0.2% to 0.45%. Therefore, preheating and drying treatment must be carried out before injection molding.

Moisture content is an important indicator in the injection molding process of plastics. Excessively high moisture content can cause defects such as silver streaks, patterns and bubbles on the surface of the product. In severe cases, it can lead to the degradation of high-molecular polymers during injection molding, affecting the intrinsic quality and appearance of the product. Among the commonly used plastic raw materials, polycarbonate, nylon, ABS, acrylic plastic, etc. are prone to absorbing moisture and need to undergo drying treatment, that is, to control the temperature of the plastic raw materials. As for other raw materials such as polyethylene, polypropylene, and polyoxymethylene, due to their very low water absorption rates, usually under good storage conditions, the water absorption rate will not exceed the allowable value, and drying treatment is not necessary.

The oil temperature refers to the temperature of the pressure oil in the hydraulic system. The temperature of the pressure oil is adjusted by the inflow and outflow of water in the chiller. The temperature of the pressure oil has a significant impact on the injection molding process. Excessively high oil temperature will reduce the viscosity of the oil, which can cause bubbles in the system, increase leakage, and lead to fluctuations in the pressure and flow of the hydraulic system, directly affecting the injection molding processing and production.

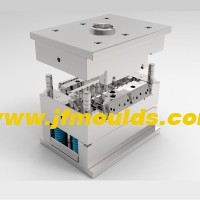

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

2. Setting of time parameters

The injection molding time parameter is an important parameter to ensure normal production. It directly affects labor productivity and the utilization rate of equipment. The time required to complete one injection molding process is usually called the molding time. The molding time includes injection time, cooling time, low-pressure clamping time, ejector time, cycle time, sol time, mold opening time, air blowing time, and preheating time of the melt bucket, etc. The time parameters are the same for different models.

(1) Injection time

The injection time generally includes the mold filling time and the holding pressure time. Generally, social time relays are used to control social actions on older models. The period from the start of the rubber injection action to the end of the rubber injection is the rubber injection time. Then switch to the timing for the pressure-holding action. For computer-controlled models, preset time parameters are used. They can be preset on the time button specified by the computer. Position control can also be adopted to switch the injection action.

(2) Cooling time

Generally, in older models, a cooling time relay is used to control the cooling action. Start the cooling time timing from the glue injection record. The cooling timing lasts until the mold opening action begins. For computer-controlled models, the parameters of the expected time engine can be used for cooling timing, and the operation can be carried out by pressing the time engine button.

(3) Low-pressure mold locking time

The setting of the low-pressure mold locking time parameter generally starts with the rapid low-pressure mold locking and stops timing before the slow high-F mold opening after the mold locking action is completed. For older models, a time relay is used to control and adjust the low-pressure mold locking time. If there are foreign objects in the mold, the screw does not extend straight, or the low-pressure mold locking time is exceeded, an alarm will start. For computer-controlled models, the low-voltage clamping time parameter is input on the keyboard to supply the low-voltage clamping time for computer control.

(4) Cycle time

The setting of the cycle time parameter is generally timed after the ejector pin has completed its operation. The time until the start and end of another cycle of the mode-locking action. The cycle time can be timed by a time relay or an electric eye signal. For computerized injection molding machines, the cycle time parameters are input on the keyboard to supply the computer with control over the cycle time.

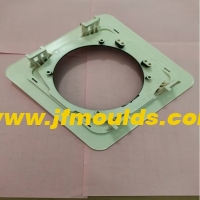

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Performance characteristics and selection criteria of injection molds

2025-06-30

Performance characteristics and selection criteria of injection molds This ...

Solutions to problems such as poor transparency, unstable dimensions, spots, and black lines in injection molded products

2025-07-31

Solutions to problems such as poor transparency, unstable dimensions, spots, and...

The glue inlet position of the mold is dragged and charred

2025-08-06

The glue inlet position of the mold is dragged and charredThe glue inlet of the ...

Classification of injection molds

2025-09-06

Classification of injection moldsDifferent types of molds have different require...

Surface treatment of molds

2025-07-26

Surface treatment of molds1. Common surface treatment processes The purpose o...

From custom development to global supply, unlock the core driving force of modern manufacturing

2025-07-19

From custom development to global supply, unlock the core driving force of moder...