Surface roughness of mold-formed parts

Surface roughness of mold-formed parts

I. Representation Methods and Meanings of Roughness

Contour arithmetic average deviation Ra value: 50 microns, 25 microns, 12.5 mu m, 6. 3 microns, 3. 2 microns, 1.60 mu m, 0.80 mu m, 0.40 mu m, 0.20 mu m, 0.10 mu m, 0.050 mu m, 0.025 mu m, 0.012 mu m, etc.

Two: Processing methods and roughness of the formed surface

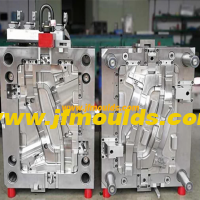

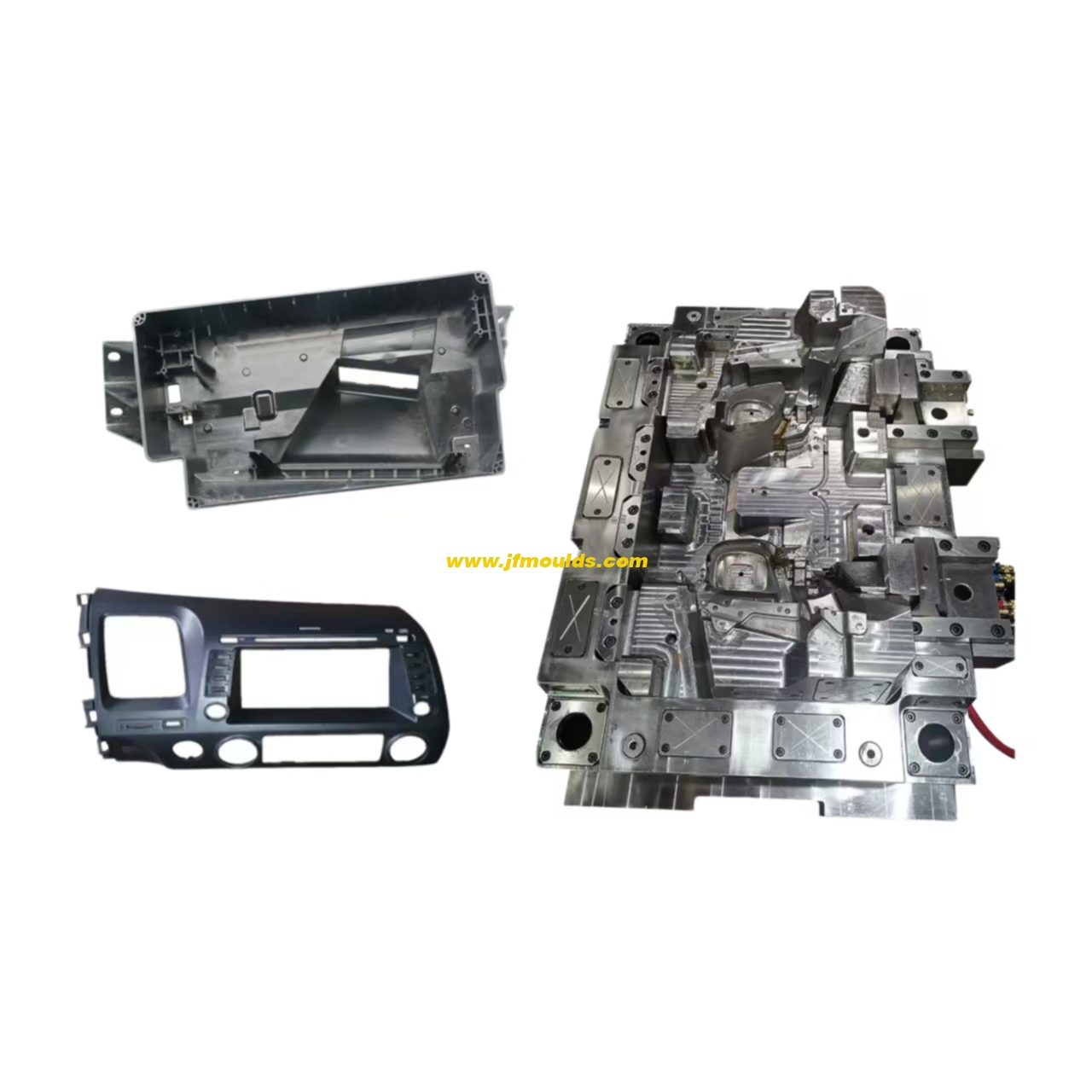

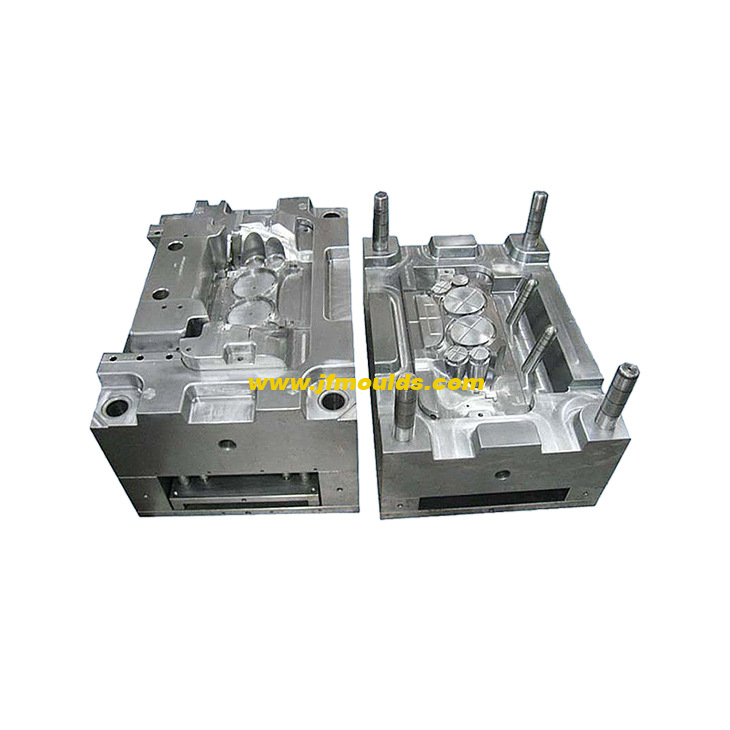

The processing methods for the cavity surface include the following types.

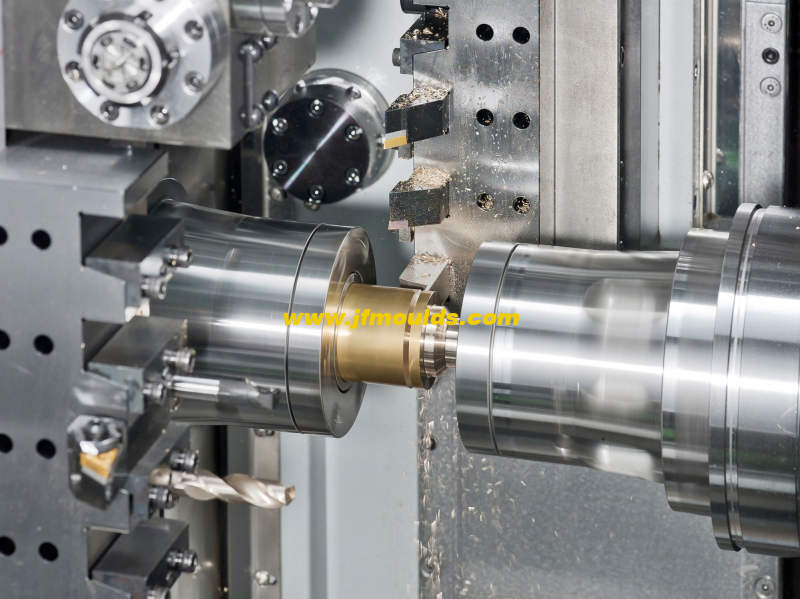

1. Mechanical processing, such as turning, milling, planing, grinding, lapping, drilling, drilling, reaming, slotting, polishing, etc.

2. Electrical processing, such as electrical discharge machining, wire cutting machining, etc.

3. Forming processing, such as precision casting, extrusion, etc.

4. Surface treatment, such as chromium plating, sandblasting, etc.

There are many methods for processing cavities, and different processing methods and the roughness that can be achieved by the same processing method.

Table mold Manufacturer in China (jfmoulds.com)

Three: Polishing of the formed surface

(1) Why does the surface of the mold need to be polished

The roughness of the mold forming surface directly affects the roughness of the plastic part surface. Due to the increasingly wide range of applications of plastic parts, customers' requirements for the surface quality of plastic parts are constantly rising. The formed surfaces obtained by ordinary mechanical processing and electrical discharge machining often fail to meet the surface roughness requirements of plastic parts. Therefore, it is necessary to carry out surface polishing treatment on the formed surface after mechanical processing or electrical discharge machining to improve the roughness of the formed surface. Polishing can be divided into ordinary polishing and mirror polishing. The roughness Ra of ordinary polishing can reach 0.2μm, while that of mirror polishing can reach 0.008μm. Mirror polishing is mainly used for the mold forming surface of transparent plastic parts. The formed surface after polishing also has the following advantages.

During injection molding production, plastic parts are relatively easy to demold.

② It can reduce the wear of the mold caused by the plastic melt

③ It can reduce the flow resistance of plastic melts.

④ It can reduce mold breakage or burst caused by temporary excessive load or fatigue

(2) How to judge the surface quality of mold forming

The following points should be noted when judging the surface quality of molds

The surface of the mold must have a geometrically correct plane without any protrusions.

When the surface of a mold is mirror-polished, the surface roughness is usually judged by the naked eye. However, it is often difficult to judge by the naked eye because a surface that is considered smooth by the naked eye may not be a completely smooth plane in the true sense of geometry

③ The surface of the mold must be completely free of any scratch marks, such as fine sand holes left by carbonized particles being pulled out or local peeling. If the quality requirements for the mold are strict, the smoothness of its forming surface can be measured by special instruments, such as the light wave refraction method or a magnifying glass, etc.

(3) Polishing techniques and processes

The polishing process and techniques are of great significance. If the techniques are used properly, the effect will surely be excellent. Conversely, if the techniques are of poor quality, not only will the roughness of the formed surface not be reduced, but the original surface quality will also be damaged, making the formed surface even rougher

Firstly, engraving molds are mostly processed by milling machines, electrical discharge machines or precision casting. If the surface of the mold is required to be smooth, the surface that has been milled must undergo rough grinding, fine grinding and polishing processes. The surfaces processed by electrodes only need to be finely ground and polished, while the molds for precision casting only need to be polished with drill gypsum.

Quick and good polishing can be achieved by grinding with a grinding wheel, first removing the tool marks left by mechanical processing. Whether using mechanical grinding or manual grinding, please abide by the following principles:

When grinding with a grinding wheel, a large amount of coolant should be used to avoid overheating, which may affect the hardness of the mold and cause local annealing of the formed surface.

② Clean and scratter-free grinding wheels or grinding stones should be selected. The higher the hardness of the steel, the softer the grinding stone should be chosen

③ Each time a finer grinding wheel is used, the workpiece and the palm of the finger must be thoroughly cleaned to avoid leaving coarse sand grains that could scratch the formed surface. The finer the grinding wheel, the more attention should be paid.

④ When a finer first-grade grinding wheel is selected each time, the direction of the mold should be changed to form a 45° Angle with the previous one, and then grinding. When the new grinding marks completely cover the direction of the previous grinding marks, add another 25% of the time to continue grinding to eliminate the deformed thin surface layer, and then select a finer grade grinding wheel.

The advantage of constantly changing the direction of the stone mill is that it can avoid the formation of irregular patterns.

When grinding large and flat molds, soft hand-held grinding discs should be avoided as much as possible. Instead, grinding stones should be selected to prevent the formation of irregular patterns

(4) Polishing precautions

Before the mold test, it is necessary to check whether the polishing fully meets the requirements or is completely completed.

② Whether the fire pattern is correct and whether it can be demolded.

③ For all mirror polishing, the steel must be ASSAB136 or NAK80, with a hardness of 52 to 54HRC.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Solutions to the problem of easy breakage at the junction of the mold's appearance color difference and material flow

2025-09-05

Solutions to the problem of easy breakage at the junction of the mold's appearan...

Exploring Injection Molds: The Precision Foundation of Industrial Manufacturing

2025-07-11

Exploring Injection Molds: The Precision Foundation of Industrial Manufacturing ...

A Comprehensive Guide to Injection Molds: From Basics to Applications

2025-07-11

A Comprehensive Guide to Injection Molds: From Basics to Applications In the vas...

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakthroughs

2025-07-15

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakt...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

The grooves of the mold's injection air inlet, the surface light and shadow, the scratches on the grooves and the size of the screw holes have increased

2025-08-13

The grooves of the mold's injection air inlet, the surface light and shadow, the...