Common defects of Injection molded products and their solutions

Common defects of Injection molded products and their solutions

The diagnosis and causes of common product defects are as follows.

(1) Product indentations

Phenomena: Depressions or bubbles, collapse pits, shrinkage, shrinkage cavities, vacuum bubbles, etc. in the product are all defects of the product.

The reason is that due to poor pressure holding and feeding, the product cools unevenly and the rubber compound in the mold cavity is insufficient, causing excessive shrinkage of the plastic. This results in dents, collapse pits, vacuum bubbles, and hollow shadows on the product surface, giving it an uneven appearance.

(2) The finished product is not satisfactory

Phenomena: Poor plastic parts, incomplete molds, and incomplete bubble surfaces are all defects of incomplete finished products.

The main reasons are poor material fluidity, insufficient feeding, poor flow of molten material filling, excessive inflation and poor exhaust, which cause incomplete filling of the mold cavity, resulting in incomplete and incomplete plastic part shape or incomplete filling of individual cavities or poor mold filling when there are multiple cavities.

(3) Product flash

Phenomenon: Excessive flash and rough edges are mostly defects of the product's burrs.

The reason is that due to poor clamping of the mold, excessive obstruction or gap at the mold edge, too good fluidity of the plastic, and excessive injection of the rubber compound, the plastic part products have extra thin wings, flaky edges, etc. along the edge.

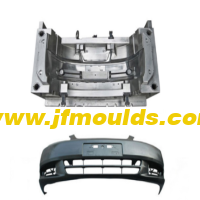

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

(4) Poor welding of the product

Phenomenon: Obvious welding marks and surface fusion lines are all defects of poor welding in the product.

The reason is that due to material contamination, excessive cooling of the rubber compound, and excessive use of mold release agents, the moisture content of the molten and mixed materials decreases, and the resin and its attachments are not miscible. These reasons lead to poor fusion during the melting and mixed material flow, resulting in obvious fine seams or weak fusion lines along the surface or inside of the product.

(5) Cracks in the product

Phenomena such as pulling crack, top crack, rupture and tortoise shell crack are all defects of product cracks.

Reasons: Due to excessive internal stress of the product, poor demolding, uneven cooling, improper plastic mixing ratio, poor performance, and poor mold design or improper parameter setting such as excessive ejection pin pressure, cracks, fine cracks, cracking or cracking under load and solvent action occur on the surface of the product.

(6) Deformation of the product

Phenomena such as deformation, warping, surface swelling, and dimensional instability are all defects of product deformation.

Reason Due to the internal stress caused by residual stress, shear stress, uneven wall thickness of the product and uneven shrinkage during injection molding, along with poor demolding, insufficient cooling, insufficient product strength, mold deformation and other reasons, the product undergoes shape distortion, warping and unevenness, deviation of the mold hole, uneven wall thickness and other phenomena Due to reasons such as poor mold strength and precision, unstable operation of injection molding machines, and unstable process technical conditions, the dimensional changes of the products are unstable.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

(7) Silver pattern on the product

Phenomena: Silver thread patterns, surface cloud patterns, surface silver patterns, etc. are all defects of silver patterns on the products.

The reason is that due to excessive moisture, excessive aeration or too much volatile matter in the plastic raw materials, the molten material is subjected to excessive shearing, the surface of the molten mold is poorly sealed, or it cools rapidly, mixes in impurities or decomposes and deteriorates, resulting in the appearance of silvery-white lustrous needle-like stripes or mica flaky patterns along the surface of the product.

(8) Discoloration of the product

Phenomena: Color differences, uneven coloration, and discoloration of the products are all defects of product discoloration.

Reason Due to poor distribution of pigments or fillers, material contamination and degradation, excessive volatile substances in materials, and decomposition of colorants and additives, plastics or pigments may change color, resulting in color differences on the surface of the products. Products with uneven color are often related to the poor thermal stability of plastics and raw materials. Uneven color in the welded part is often related to the deterioration and degradation of pigments (uneven color refers to the phenomenon where the color of the product is either darker or lighter and inconsistent with the standard color after comparison).

(9) Product corrugations

Phenomena: Surface ripples, flow patterns, plastic surface ripples, etc. are all ripple defects of the products.

The reason is that the molten material does not flow smoothly along the mold surface to fill the cavity, but rather flows in a semi-cured and fluctuating state along the mold cavity surface. There is a retention phenomenon of the molten material, causing ripples.

(10) The product is rough

Phenomena: Dull surface, rough surface, mold spots, streaks, scratches, mold marks, handprints, etc. are all manifestations of rough or unsmooth products.

The main reasons are insufficient surface finish of the mold, poor adhesion between the molten material and the mold surface, other impurities adhering to the mold or surface marks after mold maintenance and repair, improper operation, lack of cleanliness, and improper setting of parameters such as material temperature and mold temperature, which result in the product surface being not bright, having marks, not smooth, scratches and scars, mold marks, and the surface being milky white or whitish.

(11) Bubbles in the product

Phenomenon: Defects such as internal vacuum bubbles in the product or bubbles in expanded products.

The reason is that due to excessive inflation or poor venting in the molten material, the remaining monomers, gases and moisture inside the product form small or string cavities or vacuum bubbles.

(12) The product sticks to the mold

Phenomena: Poor demolding, plastic part sticking to the mold and other defects.

The reason is that due to material contamination or non-drying, poor demolding performance of the mold, overly strong filling effect, etc., the products are difficult to demold or deform or crack after demolding, or the residual direction of the products does not meet the design requirements.

(13) The products delaminate and peel off

Phenomena: Defects such as delamination and peeling of mica flakes, and layered plastic at the gate.

The reason is that due to improper raw material mixing ratio, improper material temperature or mold temperature, uneven plasticization, and excessive shear force when the molten material flows along the mold surface, the material peels off in thin layers, resulting in a decline in the physical properties of the product.

(14) Gate sticking to the mold

Phenomena: Gate or sprue blockage, broken glue, broken pins, runner sticking to the mold, and sprue sticking to the mold are all gate sticking defects. In mild cases, the mold sticks; in severe cases, it gets clogged.

The reason is that due to insufficient design of the gate opening and the slope of the gate, the limited force acting inside the gate sleeve, or insufficient cooling, the gate adheres to the gate sleeve or blocks the sprue, etc.

(15) The product is cloudy

Phenomenon: Poor transparency, turbidity defect at the gate of the product.

The reasons are as follows: Due to material contamination and poor drying, poor contact between the molten material and the mold surface, fine depressions on the product surface causing random light scattering or plastic decomposition, and the presence of impurities and waste materials, the mold surface is not bright, and the exhaust is not good, which can cause the transparent plastic to be poorly transparent or uneven.

(16) Spots on the product

Phenomenon: Black spots, black lines, yellow spots, yellow lines, black stripes, brown stripes, etc. on the product are all spot defects of the product.

Reason: Due to the decomposition of plastic or the decomposition and combustion of flammable volatile substances, air, etc. in the material under high temperature and high pressure, the burned resin is injected into the mold cavity along with the molten material, presenting various spots on the surface of the product, such as black spots, yellow spots, black stripes, brown stripes, etc., or along the surface of the product, it shows a grayish burn.

(17) Stiff lumps of the product

Phenomenon: Defects such as cold lumps or hard lumps in the product.

The reason is that due to the addition of cold materials or poorly plasticized rubber compounds, these unplasticized and insufficiently plasticized materials cause the plastic products to be undercooked.

(18) Glue leakage

Phenomena: Defects such as material overflow and glue dripping from the nozzle.

The reasons are: The temperature setting of the barrel and the nozzle is improper, the contact between the nozzle and the main gate die is poor, the clamping force is uneven or unstable, the fluidity of the plastic is too good, and the temperature of the nozzle is too high, resulting in the phenomenon of glue leakage and material overflow.

Defects in injection molding products are the root cause of substandard product quality, and these defects are also related to the technical proficiency of injection molding operators and maintenance workers. To ensure product quality, injection molding operators are required to have rich practical experience in injection molding machines and process technologies. One should be familiar with and understand the performance of the injection machine being used, and have a comprehensive grasp and application of it. It is necessary to have a comprehensive grasp of injection molding process technology and master the entire process setting and calibration from plastic raw materials to product packaging.

During the injection molding operation process, common product defects also have certain trends. The common practice is to accurately identify and diagnose product defects, comprehensively analyze the possible causes, and combine practical work experience to explore a set of rules. Through the setting of plastic raw materials, various temperature parameters, pressure parameters, speed parameters, stroke parameters, and time parameters, In light of specific circumstances such as molds, nozzles, melt tubes, screws, as well as lubricants and mold release agents, reasonable parameter presetting and modification should be carried out. The process technical parameters should be adjusted and corrected in combination with the actual situation. Through calibration and trial operation, product defects can be prevented and product quality can be guaranteed to be qualified.

Processing equipment_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Surface roughness of mold-formed parts

2025-10-13

Surface roughness of mold-formed partsI. Representation Methods and Meanings of ...

From custom development to global supply, unlock the core driving force of modern manufacturing

2025-07-19

From custom development to global supply, unlock the core driving force of moder...

The structure, materials and design of injection molds

2025-07-18

The structure, materials and design of injection molds In the vast landscape ...

Diversification of injection mold enterprises

2025-06-28

Diversification of injection mold enterprises1. Automotive Molds: Driving Indust...

Dimension marking of the mold design drawing

2025-09-10

Dimension marking of the mold design drawingI. General Requirements for Dimensio...

The decisive methods for the height of the water outlet position beside the mold housing, the damage and deformation of the front mold cavity

2025-08-28

The decisive methods for the height of the water outlet position beside the mold...