The positioning ring and screws of the mold

The positioning ring and screws of the mold

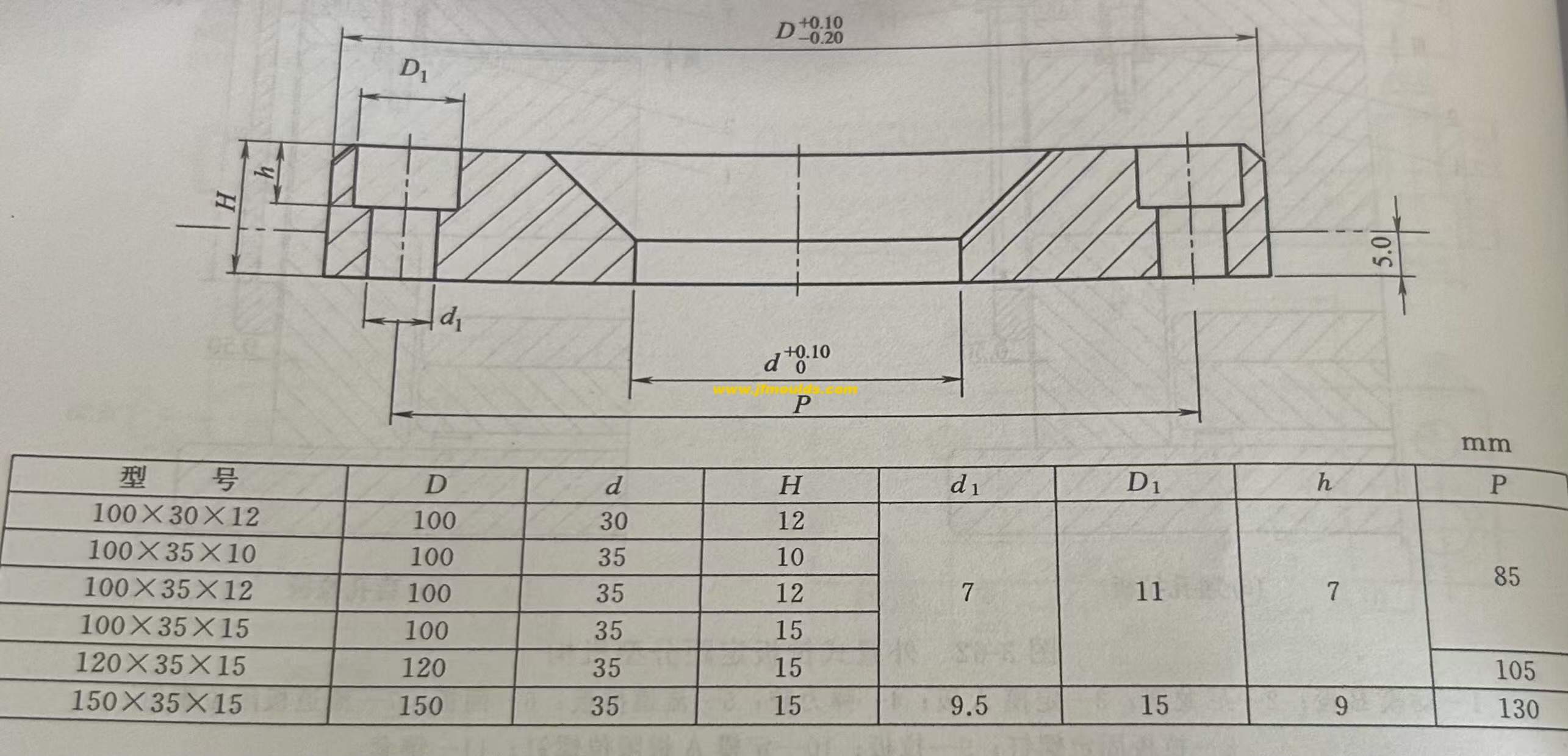

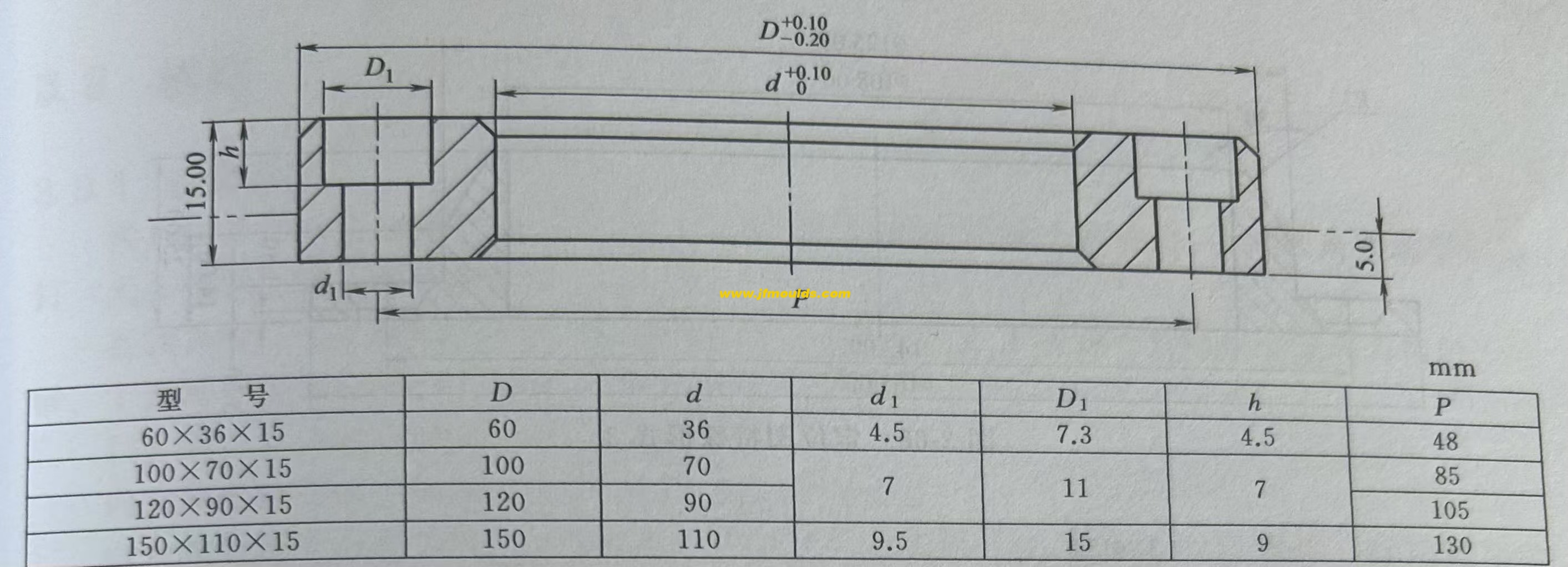

One: Positioning circle

There are two basic forms of positioning rings, and the materials of positioning rings are S45C or S50C.

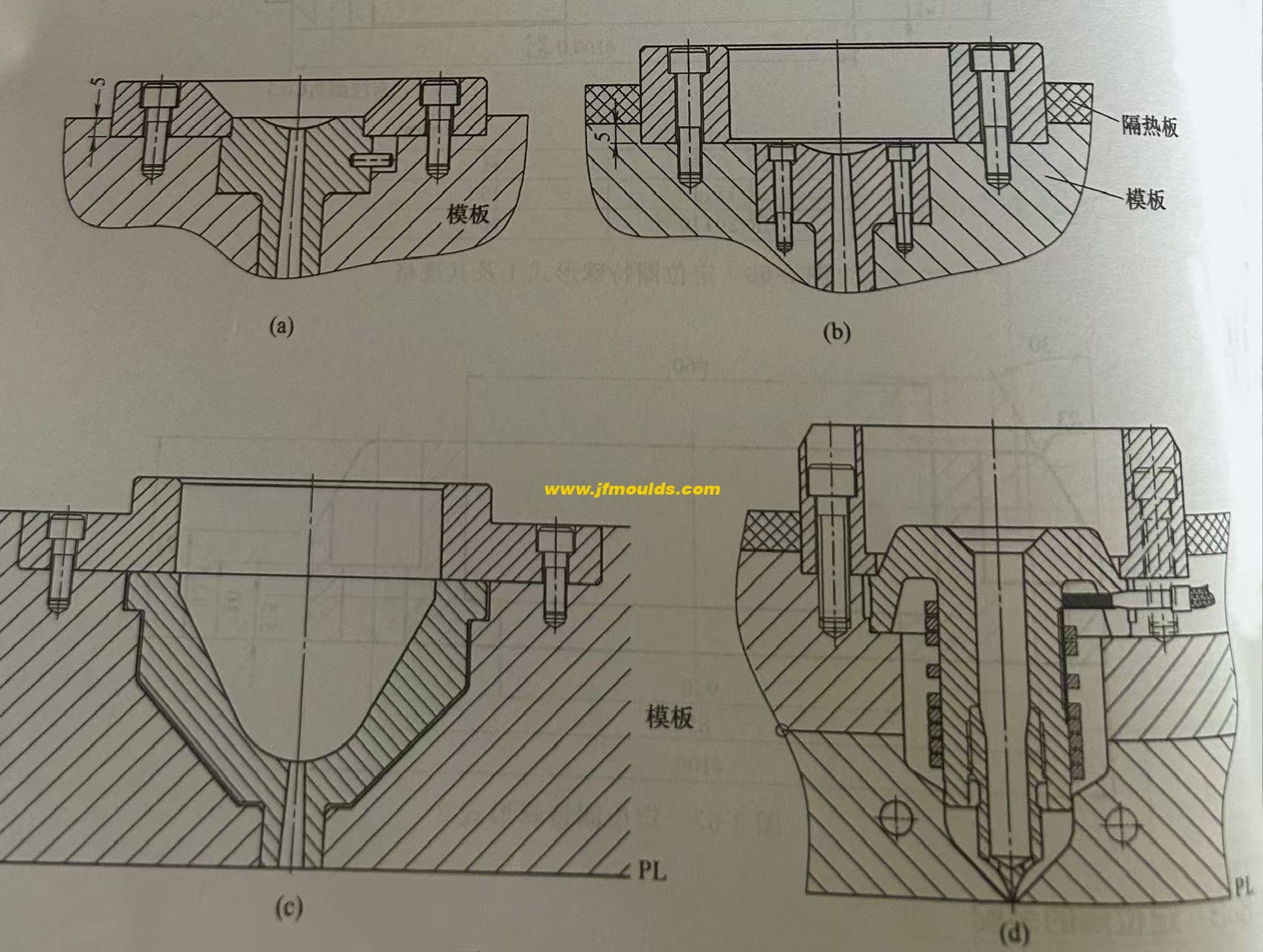

1. The positioning ring is embedded in the template by 5mm during assembly and directly presses against the gate sleeve.

2. When assembling the positioning ring, 5mm is also embedded in the template, but it does not directly press the gate sleeve. The gate is positioned by being pressed by the template.

Turnover box mold Manufacturer in China (jfmoulds.com)

Positioning ring assembly

Two: Screws

1. Tighten the screws

The commonly used fastening screws in molds are mainly divided into hexagon socket cylindrical head screws (hexagon socket screws), hexagon socket flat-end set screws (headless screws) and hexagon socket head bolts.

In the mold, the fastening screws should be selected in different preferred specifications of different types according to different needs, while ensuring uniform and sufficient fastening force. The following is an explanation of the usage conditions of various types of fastening screws.

Hexagon socket cylindrical head screws

Preferred specifications for hex socket screws :M4, M6, M10, M12.

Hexagon socket screws are mainly used for front and rear die materials, cores, small inserts and some other structural components. In addition to the aforementioned positioning

Except for the screws used in the round and gate sleeves, the screws used in other components such as inserts, cores, and fixing plates should be selected based on their applicability as much as possible

Priority specifications, screws used for fastening the inserts of moving and fixed molds, when selected, should meet the following requirements.

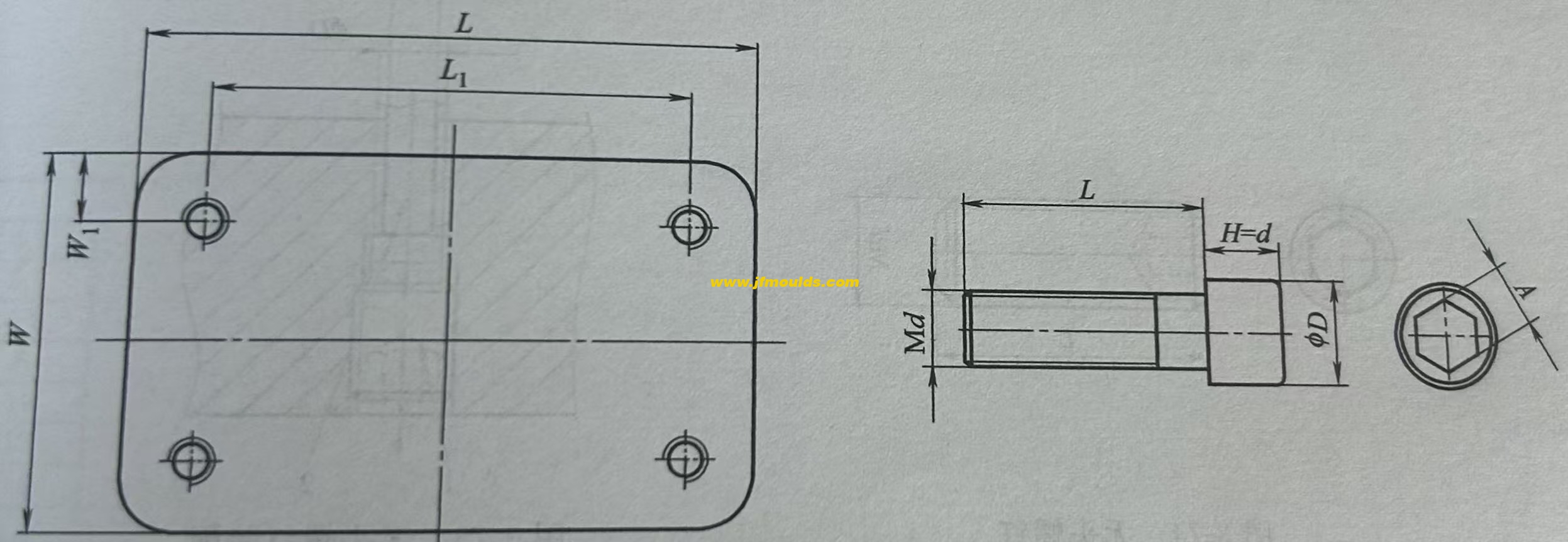

① Size and quantity: The size and quantity of the fastening screws.

② Position: The screw holes should be arranged at the four corners and symmetrically. The size W from the screw hole to the edge of the insert; Take 1 to 1.5 times the diameter of the screw hole. L1 should refer to the size of the processing fixture and is generally taken as a multiple of 15 or 25.

③ Specifications of hexagon socket cylindrical head screws: Hexagon socket screws, imperial specifications, metric specifications.

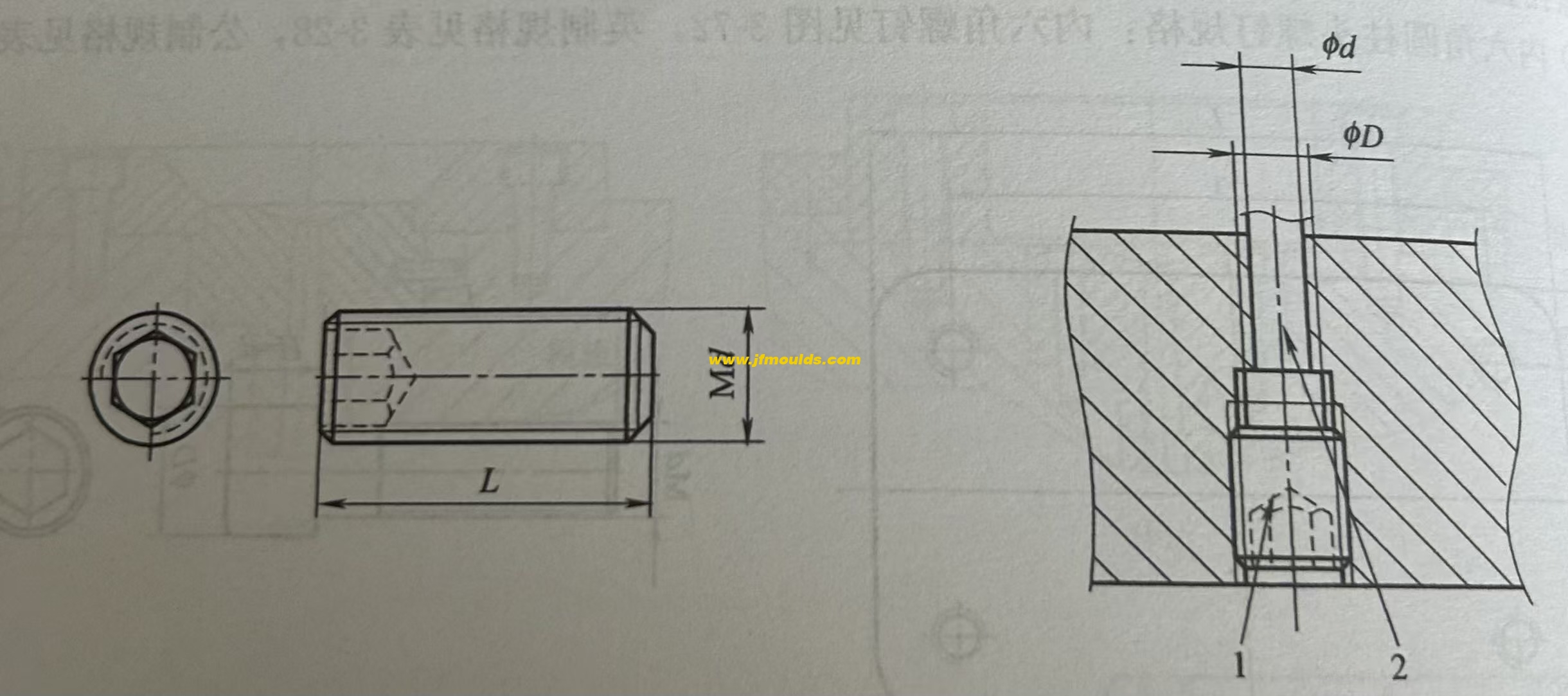

(2) Hexagon socket screws

It is less used in molds and is usually only used as a garbage nail. The types and specifications selected are limited, and the following two specifications are generally chosen.

In standard parts, ΦD and Φd are interrelated. Φd is the actual size used, so Φd is usually taken as the basis for selection and selected according to the following range.

When d is 3.0mm or 9/64in,

Choose M8;

When d is 3.5mm or 5/32in, M10 should be selected.

When the thickness is 7.0mm or 3/16in, select M12.

When d is 8.0mm or 5/16in, M16 should be selected.

When d is 8.0mm or 5/16in, it should be fixed with a pressure plate.

Limit screw

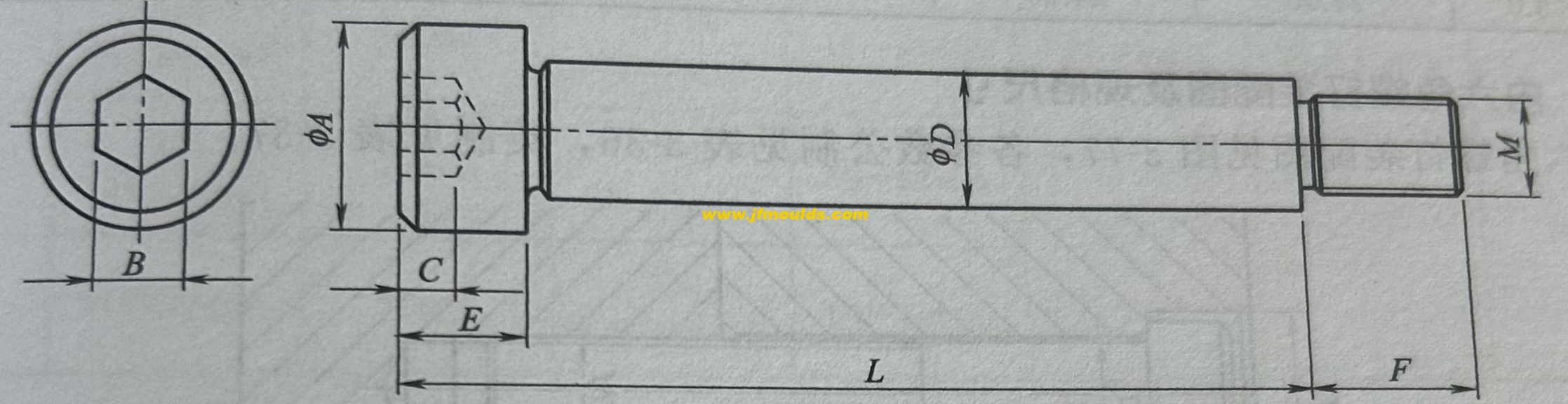

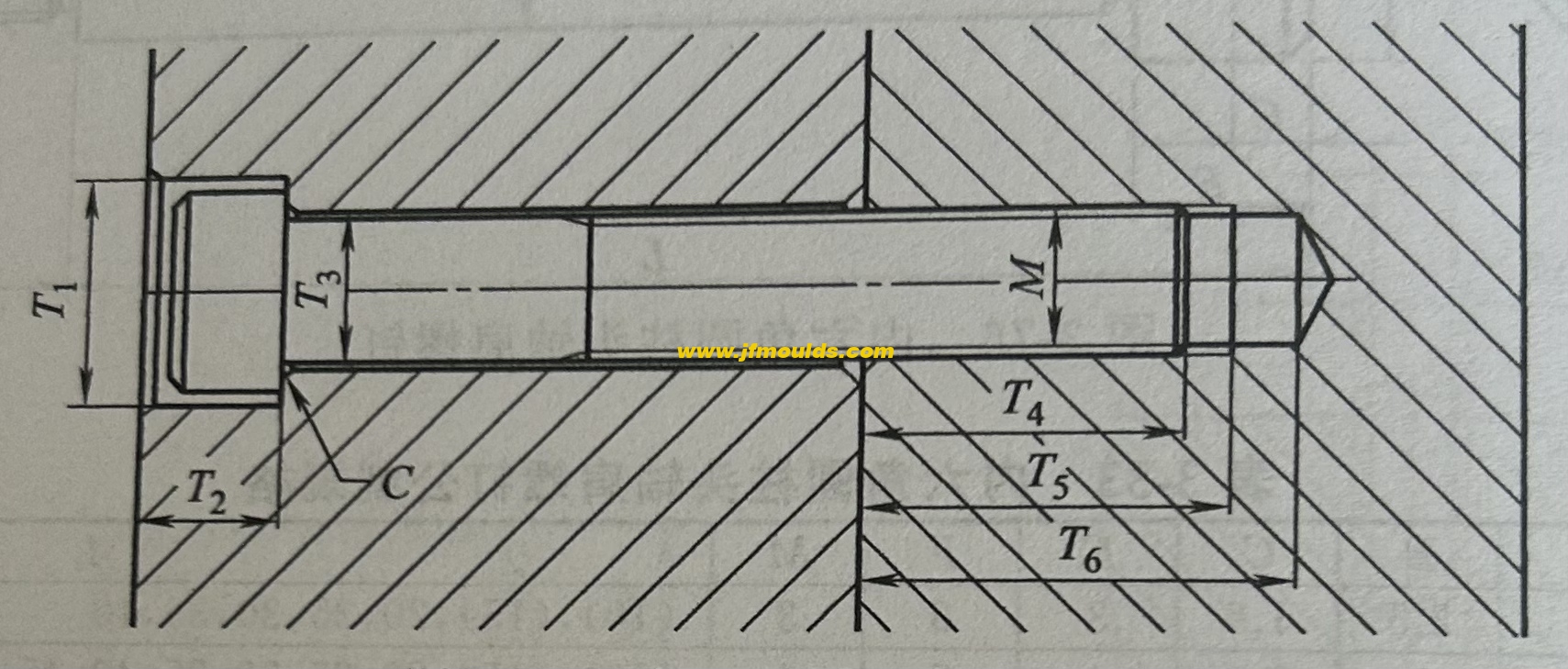

The limit screws commonly used in molds are hex socket cylindrical head shaft shoulder screws, also known as sanda screws.

Assembly drawing and specification dimensions of hexagon socket screws

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

NowOn behalf of the manufacturing industry precision "molding magician"

2025-06-29

NowOn behalf of the manufacturing industry precision "molding magician" In today...

The cavity arrangement and parting surface of the mold

2025-10-09

The cavity arrangement and parting surface of the mold Forming parts refer ...

The key to plastic product molding

2025-07-21

The key to plastic product moldingBehind today's dazzling world of plastic produ...

Solutions to the problem of easy breakage at the junction of the mold's appearance color difference and material flow

2025-09-05

Solutions to the problem of easy breakage at the junction of the mold's appearan...

The causes and solutions of dents on injection molded products, incomplete finished products, and flash on products

2025-07-29

The causes and solutions of dents on injection molded products, incomplete finis...

The causes and solutions of silver streaks, discoloration, surface ripples and roughness in injection molded products

2025-07-30

The causes and solutions of silver streaks, discoloration, surface ripples and r...