Solutions to surface flow patterns, deformation and ejection deformation on both sides of the mold

Solutions to surface flow patterns, deformation and ejection deformation on both sides of the mold

The surface flow pattern of the mold

Phenomenon: Flow patterns often appear on the surface of transparent lenses during the production process.

Analysis: Slow speed will cause the melt to cool down too quickly, and the surface temperature of the mold will be too low. The position switch is too early.

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 50t, plasticizing capacity: 64g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: fan-shaped gate, ejection method: Ejection with ejector pins, mold temperature: 70℃ (constant temperature machine)

(3) Product characteristics

Material: PMMA 8N, Color: Transparent, Product weight (single piece) : 1.5g, nozzle weight: 13g

(4) Analysis of causes of defects

The mold temperature is low and the injection speed is relatively slow, causing the melt to cool down too quickly.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, for the second section, fill it slowly and in a very small position near the glue inlet. The third section should be filled rapidly to 90% of the mold cavity to prevent the high-temperature molten rubber from cooling and forming wavy patterns. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Automobile parts mold Manufacturer in China (jfmoulds.com)

Deformation of the mold

Analysis: 1. The mold temperature is too high; 2 Insufficient cooling time; 3. The molding cycle is too short.

Characteristics of injection molding machines

Grade: DEMAG: Clamping force: 50t, plasticizing capacity: 64g

(2) Mold characteristics

Mold ejection number: 1x2, injection method: fan-shaped gate, ejection method: Ejection with ejector pins, mold temperature: 70℃ (constant temperature machine)

(3) Product characteristics

Material: PMMA 8N, Color: Transparent, Product weight (single piece) : 1.5g, nozzle weight: 13g

(4) Analysis of causes of defects

The mold temperature is too high and the molding cycle is too short, resulting in the product not cooling down sufficiently after being demolded.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. Appropriately reduce the mold temperature.

3. Appropriately increase the cooling time and molding cycle.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

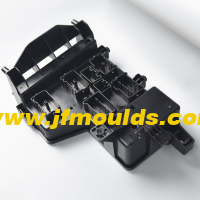

The two sides of the mold protrude and deform

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 100t, plasticizing capacity: approximately 150g

(2) Mold characteristics

Mold ejection number :1+1, glue injection method: horn gate, ejection method: Ejection with ejector pins, mold temperature: 105° C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC HI-1001BN W91605 color: grey product weight (single piece) : 4.27g, spout weight 12.62g

(4) Analysis of causes of defects

1. Because the bottom shell is more difficult for the glue to pass through than the face shell, when the face shell is full, the bottom shell still needs to be filled with glue, causing the face shell to be overly full during molding and thus sticking to the later mold.

2. This area is close to the glue inlet and has many bone positions. When the mold is ejected, it sticks to the rear mold, causing the product to deform.

(5) Countermeasures

1. Increase the water entry size of the bottom shell

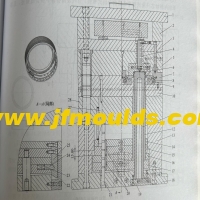

2. Add two flat ejector pins at the deformed top, as shown in the specific figure.

Related News

Limit pins and springs of the mold

2025-10-04

Limit pins and springs of the moldOne: Limit pinThe function of the limit nail i...

Solutions to the uneven surface of the mold, the whitening of the bone position due to trapped air, the air lines at the glue entry points, and the lack of glue

2025-08-25

Solutions to the uneven surface of the mold, the whitening of the bone position ...

Thread demolding

2025-11-17

Thread demolding(1) Forced demolding of the thread The mold structure of th...

Injection molds: From millimeter-level precision to the invisible engine of industrial transformation

2025-07-07

Injection molds: From millimeter-level precision to the invisible engine of indu...

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

How can the surface dirt, water line inclusion and warping deformation of the mold be solved

2025-08-30

How can the surface dirt, water line inclusion and warping deformation of the mo...