The dimensional tolerance of injection mold fit and the surface roughness of mold parts

The dimensional tolerance of injection mold fit and the surface roughness of mold parts

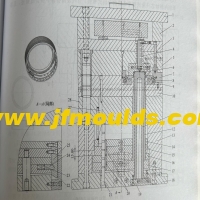

One: Dimensional tolerance of injection mold fit

When there are purchased parts among the mating parts of the mating dimensions, the mating relationship should be reasonably determined within the cost and manufacturing range, taking into account the mold requirements and the dimensional limit deviations of the purchased parts provided by the supplier, such as the fit between the push rod and the rod hole.

2. The fit dimensions refer to the fit between the formed parts (such as the fit between the core and the insert)

For common molds: When the basic size is 50mm, H7/js7 is used in combination.

When the basic size is between 50mm and 250mm, H7/k6 is used in combination.

When the basic size is 250mm to 630mm, H6/h5 is used in combination

Precision mold: When the basic size is 30mm, H7/js7 is used in combination.

When the basic size is 30mm to 180mm, H6/js6 is used in combination.

When the basic size is between 180mm and 400mm, H6/h5 is used in combination.

Crate mold Manufacturer in China (jfmoulds.com)

3. The fit dimensions are sliding fits (such as the fit between inserts and inclined tops, sliders, straight tops, push blocks, etc.)

For common molds: When the basic size is 10mm, H7/g7 is used in combination.

When the basic size is between 10mm and 30mm, H7/g6 should be used in combination.

When the basic size is 30mm< 50mm, H6/g5 should be used in combination.

When the basic size is 50mL to 120mm, H6/g5 is used in combination.

Precision mold: When the basic size is 18mm, H6/g6 is used in combination.

When the basic size is 18mm less than 30mm, H6/g5 should be used in combination.

When the basic size is 30mm to 80mm, H6/g5 is used in combination.

Two: The surface of the mold parts is rough

1. Classification of surface roughness of molds

The surface roughness of the mold includes the surface roughness of the cavity, the surface roughness of the gating system, and the surface roughness of the sealing surface. According to the working

conditions and processing technology of the mold, a reasonable surface roughness of the parts should be determined, and the direction of the processing texture or polishing texture of the square

plate should be as consistent as possible with the sliding or demolding direction.

2. Tolerance and roughness requirements for the mold base

When there are special requirements for the formwork, the requirements of the drawings shall prevail.

Three: Selection of surface roughness values

The selection principle of surface roughness values: Under the premise of meeting the functional requirements of the part surface, try to choose a larger roughness value.

Four: Other Requirements

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

1. Height requirements for the mold push rod

The end face of the push rod for ejecting the plastic part should be flush with the surface of the corresponding mold cavity. For ordinary molds, the end face of the push rod is allowed to be no more

than 0.10mm higher, while for precision molds, it is allowed to be no more than 0.05mm higher.

2. Height requirements for the reset rod of the mold frame

The end face of the reset rod of the mold base should be flush with the parting surface of the mold. For ordinary molds, the allowable subsidence should not exceed 0.05mm, and for precision molds, it

should not exceed 0.02mm

3. Assembly requirements for core and inner mold inserts

After the fixed and moving mold inserts, cores, etc. are assembled with the tail shoulder, their end faces should be flush with the end faces of the assembled parts. For ordinary molds, the allowable

settlement should not exceed 0.05mm, and for precision molds, it should not exceed 0.02mm.

4. Technical requirements for chromium plating on the surface of mold cavities

The surface of the chrome-plated cavity should be polished first. The thickness of the chromium layer should be 0.01 to 0.05mm. The chromium layer should be uniform and consistent, and defects

such as chromium accumulation, corrosion and peeling are not allowed.

5. Regarding the dimensions where the cavity surface and other surfaces influence each other

The dimensional tolerances of the dimensions that affect the cavity surface should first take into account the requirements of the forming surface.

Related News

Solutions to the deformation at the sprue position of the mold, the flash at the round top pin position (excessive glue), and the baking mark at the glue inlet position

2025-09-02

Solutions to the deformation at the sprue position of the mold, the flash at the...

Thread demolding

2025-11-17

Thread demolding(1) Forced demolding of the thread The mold structure of th...

Solutions to the problems of hard rubber indentation, row position demolding and inconsistent product dimensions in molds

2025-08-29

Solutions to the problems of hard rubber indentation, row position demolding and...

The new business card of "Mold Capital" is fully started.

2025-06-19

Recently, at the construction site of the Huangyan Mould Intelligent Manufacturi...

The solutions for the air marks at the arrow position in the mold direction, the black shadow lines (fusion lines) on the surface, and the trapped air and white spots at the lamp hole position

2025-08-13

The solutions for the air marks at the arrow position in the mold direction, the...

Solutions for trapped gas burning, surface wire clamping and insufficient glue in the inner column of the mold

2025-08-11

Solutions for trapped gas burning, surface wire clamping and insufficient glue i...