Design of Injection mold gating system

Design of Injection mold gating system

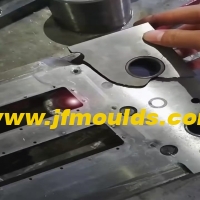

The injection system of an injection mold refers to the melt flow channel from the nozzle of the injection molding machine to the entrance of the cavity. It can be divided into two major types: the common runner gating system and the hot runner gating system.

The determination of the flow direction, cross-sectional shape and size of the runner, the design of the porcelain common runner gating system includes the selection of the main runner, the selection of the gate position, the determination of the gate form and the gate cross-sectional size. The design of the hot runner mainly includes the design of the hot jet nozzle and the hot runner plate, etc.

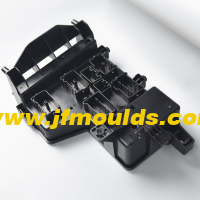

chair injection mold Manufacturer in China (jfmoulds.com)

I. Principles and Key Points of Gating System Design

1. Design principles of the gating system

The principle of quality first

The design of the washing and injection system has a significant impact on the quality of the plastic parts. Firstly, the gate should be set at the most easily accessible part of the plastic part, while minimizing the impact on the appearance of the plastic part as much as possible. Secondly, the position and form of the gate will directly affect the molding quality of the plastic part. An unreasonable injection system can cause defects such as weld marks, poor filling, and flow marks on the plastic part, and even lead to the failure of a mold.

(2) The principle of feed balance

In single-cavity injection molds, the distance between the mouth position and all parts of the cavity should be as equal as possible to ensure that the melt fills every corner of the cavity simultaneously. In multi-cavity injection molds, the runner channels to each cavity should be as equal as possible to ensure that the melt can fill all cavities simultaneously. In addition, the same plastic parts should be fed from the same position to ensure their interchangeability.

(3) The principle of minimum volume

The arrangement of the cavity should be as compact as possible, the flow of the gating system should be as short as possible, the shape and size of the runner cross-section should be reasonable, and the volume of the gating system should be as small as possible. Specifically, there are the following benefits.

1.The less heat and pressure the melt loses in the gating system.

2.The lighter the exhaust burden of the mold.

3.The less heat the mold absorbs from the gating system, the easier it is to control the mold temperature.

4.The shorter the time the melt flows in the gating system, the shorter the injection cycle will be.

5.The less concrete there is in the gating system, the less plastic is wasted.

6.The smaller the external dimensions of the mold are.

(4) The principle of the shortest cycle

When one mold and one cavity are used, efforts should be made to ensure that the melt fills every corner of the cavity in approximately the same amount of time. When multiple cavities are molded in one mold, it is necessary to ensure that each cavity is filled within approximately the same amount of time. This way, not only can the molding quality of the plastic part be guaranteed, but also the injection molding cycle can be minimized. When designing the gating system, it is also necessary to find ways to reduce the resistance of the melt, increase the filling speed of the melt, minimize the bending of the runner, and when curves are needed, arc transitions should be adopted as much as possible. However, the practice of polishing the flow channel surface to a very low roughness in order to reduce melt resistance is often not advisable. The reason is that an appropriate roughness can leave the cold material at the front end of the melt on the flow channel wall (the flow channel wall is equivalent to countless tiny cold material cavities). Under normal circumstances, the surface roughness Ra of the flow channel can be taken as 0.8 to 1.6μm.

Paint bucket mold Manufacturer in China (jfmoulds.com)

2 Key Points of the gating System design

When designing the injection system, the first consideration should be to enable the plastic melt to fill the cavity rapidly, reducing pressure and heat loss. It should be economically considered to minimize the proportion of waste generated by the flow channel as much as possible. Finally, the gate marks on the plastic part should be easily removed. The key points of the porcelain injection system design are as follows.

The position of the gate should ensure that when the plastic flows into the cavity, it faces the wide and unobstructed part of the cavity, that is, the melt should flow from the thick-walled part of the cavity to the thin-walled part. If the melt flows from the thin-walled area to the thick-walled area, the speed will drop rapidly and the temperature will also drop sharply, which is not conducive to filling.

2. To prevent the plastic from directly hitting the cavity wall, core or insert when flowing into the cavity, it is necessary to ensure that the plastic melt can flow to all parts of the cavity as soon as possible and avoid deformation of the core or insert

3. Try to avoid causing weld marks on the plastic parts or having them appear in unimportant parts of the product.

4. The position of the gate and the direction of plastic inflow should ensure that the plastic flows uniformly along the parallel direction of the cavity when entering it and facilitate the discharge of gas inside the cavity.

5. If fully automatic operation is adopted during production, it is necessary to ensure that the concrete in the gating system can be automatically demolded smoothly along with the plastic part.

6. The gating system should have a good exhaust structure and sufficient cold material cavities to minimize the introduction of air and cold material into the cavity, which may affect the quality of the plastic part.

When there are multiple cavities in one mold, it is necessary to prevent plastic parts of significantly different sizes from being placed in the same mold. If the volume of the large and small plastic parts differs by more than four times, it is very difficult to achieve balanced feeding.

When the projected area of the plastic part is large, when designing the gating system, it is necessary to avoid opening a gate on one side of the mold, otherwise it will cause uneven force distribution during injection molding.

The design of the gating system should take into account shortening the production cycle and improving labor productivity.

Related News

Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in molds

2025-08-15

Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in ...

Treatment methods for mold weld marks/shrinkage marks and fractures

2025-08-09

Treatment methods for mold weld marks/shrinkage marks and fracturesMold weld mar...

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

Explore Huangyan Mould Industry in Deepseek Eyes Together

2025-06-19

1. development process and industrial scale 01 historical evolution Huangyan mol...

The trapped air adjustment of the mold is difficult, and the deformation and the bottom row position pulling mold treatment method of the face shell

2025-08-12

The trapped air adjustment of the mold is difficult, and the deformation and the...

How to solve the problems of whitening, charring and deformation of the bone position at the water outlet of the mold

2025-08-16

How to solve the problems of whitening, charring and deformation of the bone pos...