Determination of mold base size

Determination of mold base size

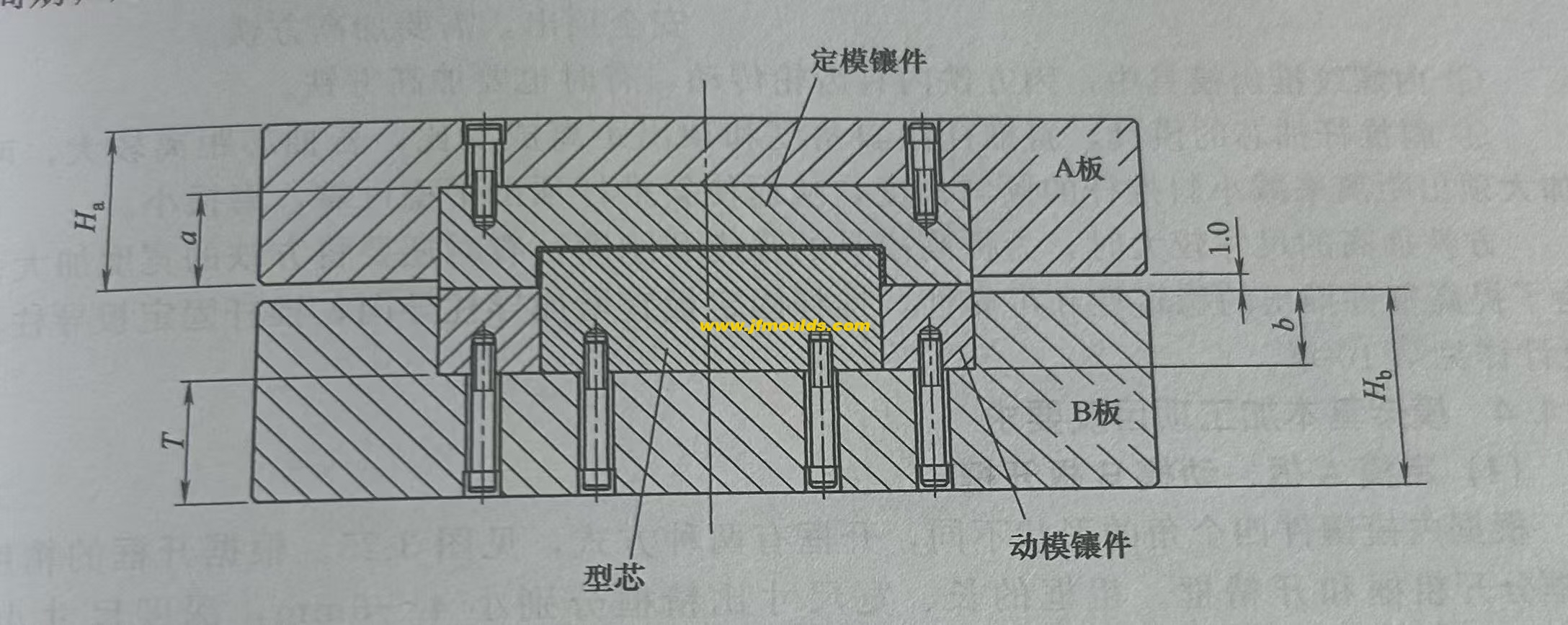

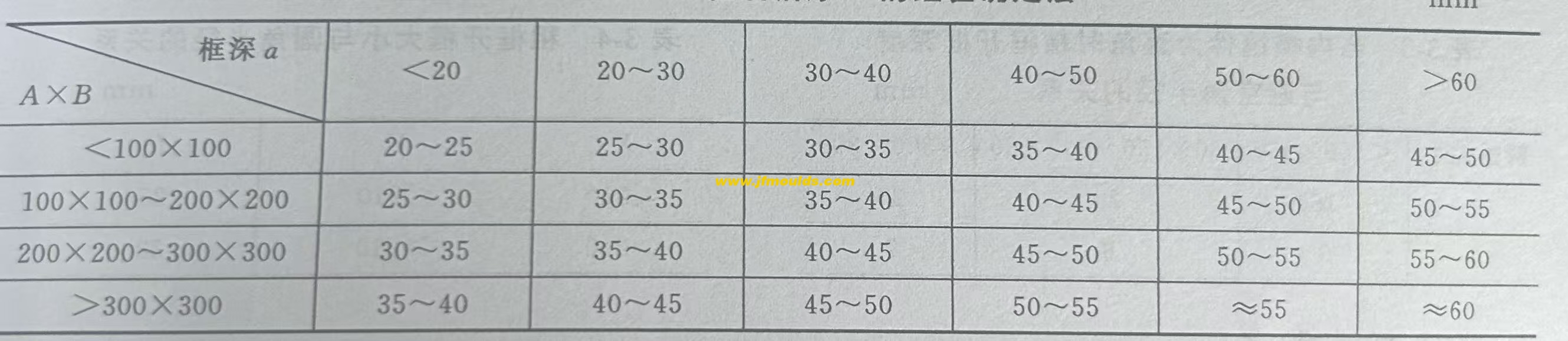

1: Determine the length, width and height of the fixed mold A plate and the moving mold B plate

The size of the mold base depends on the external dimensions of the molded parts (inner mold inserts), and the external dimensions of the molded parts depend on the size, structural characteristics and quantity of the plastic parts. From an economic point of view, the more compact the structural size of the mold is the better, provided that it meets the requirements of stiffness and strength.

The mold base is a standard part, as long as the length, width, and height of the fixed mold A plate and the moving mold B plate, the size of other templates, and other standard parts (such as screws and reset rods, etc.) are determined accordingly. Therefore, here we mainly discuss how to determine the length, width and height of the fixed mold A and moving mold B plates, and the determination of the shape size of the molded parts and the size of the mold base has been described in detail in Section 3.4. In the process of mold design practice, the following methods are commonly used to determine the length, width and height dimensions of A and B plates.

Plastic spoon injection mold Manufacturer in China (jfmoulds.com)

(1) Determination of the length and width of plates A and B.

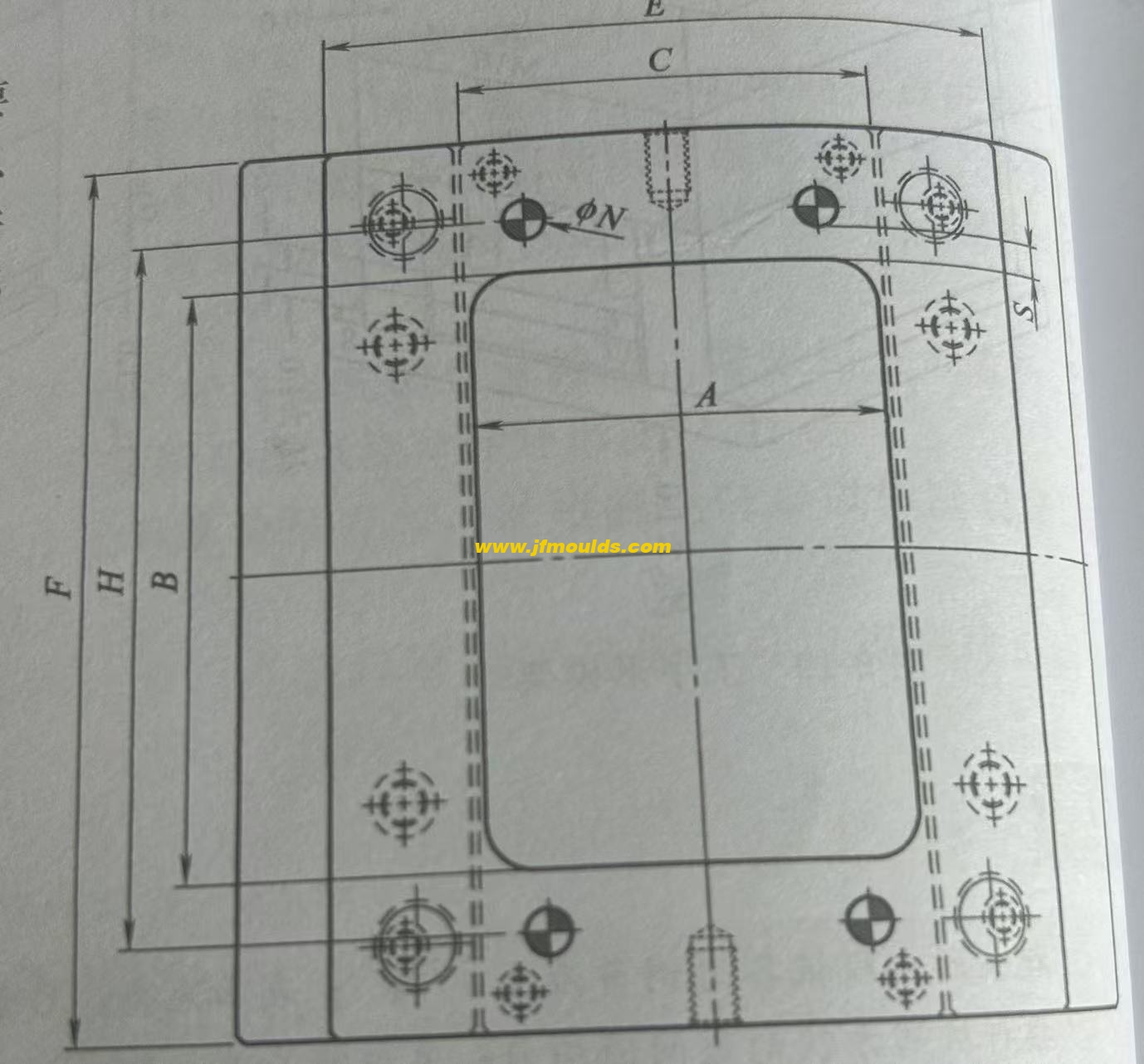

After the length and width dimensions A and B of the inner mold insert are determined, the length, width and dimensions E and bottom of the mold base can be determined.

Generally speaking, in molds without lateral coring, the open frame size A of the template should be roughly equal to the width size C of the pushrod plate of the mold base. In standard mold bases, dimensions C and E correspond, so if you know size A, you can find the mold base width size E in the standard mold base manual.

When the width size E of the template is determined, the diameter N of the reset rod is also determined. In the absence of upper and lower lateral coring, it is generally 10mm to S≈, that is, H= B N 20(mm)

In the standard mold base, sizes H and F also correspond to each other, so if you know size H, you can find the mold base length size F in the standard mold base manual.

When the mold has a lateral core pulling mechanism, the mold base should be enlarged accordingly according to the size of the slider.

Small slider (slider width≤80mm): The length and width of the mold are increased by 50-100mm on the basis of the above determination.

Medium slider (80mm< slider die width ≤200mm): The length and width of the mold are increased by 100-150mm on the basis of the above determination.

Large slider (slider width >200mm): the length and width of the mold are increased by 150-200mm on the basis of the above determination.

The height of the fixed template should be as small as possible for two reasons: reduce the length of the main channel, reduce the exhaust burden of the mold, and shorten the molding cycle; When the mold is installed on the injection machine for production, it is close to the injection machine and there is no aftermath of deformation.

Height of the B plate of the moving mold: generally equal to the depth of opening the frame plus 30-60mm. The height of the movable template should be taken as much as possible as standard values as possible, and non-standard formwork should be avoided.

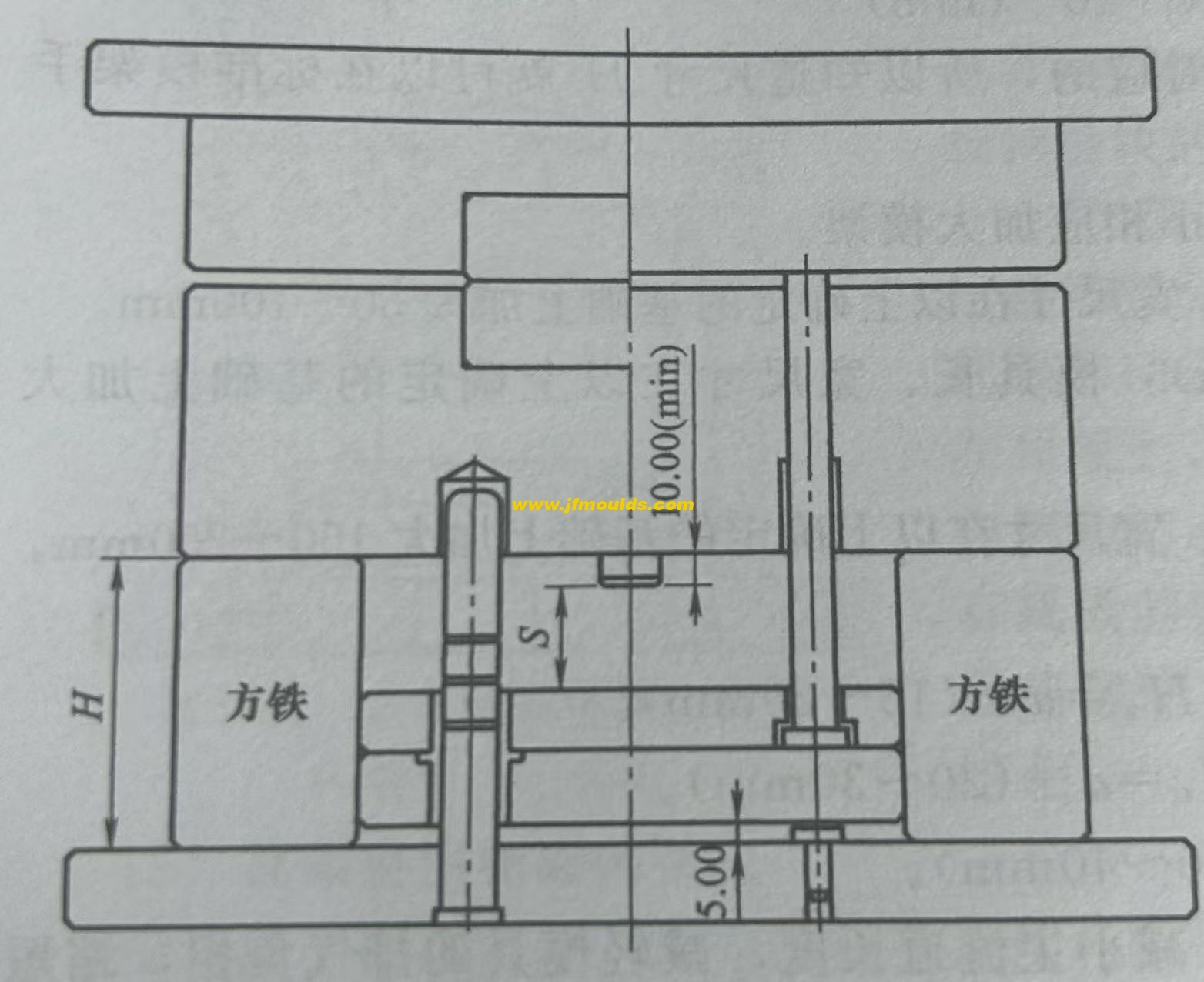

2: The height of the square iron

The height of the square iron must make the pusher plate have sufficient push distance S to ensure that the plastic part is safely separated from the mold.

The height of the square iron has been standardized, and under normal circumstances, when the length, width and height of the fixed mold A plate and the moving mold B plate are determined, the height of the square iron can also be determined. However, for the same length and width of the formwork, there are three standard heights of square iron, one of which is the standard height of non-height, and the other two are the standard height after heightening.

In the following cases, the square iron needs to be raised.

1. The plastic parts are very deep or very high, the ejection distance is large, and the height of the standard square iron is not enough.

2. The double push plate is ejected for the second time, because there are four plates in the square iron, which reduces the ejection distance of the pusher plate, and in order to safely eject the plastic parts, it is necessary to increase the square iron.

3. The internal thread is pushed out of the mold, because there is a gear drive in the square iron, and sometimes the square iron needs to be higher.

4. The mold of the inclined pusher core, the inclination angle of the inclined pusher is inversely proportional to the ejection distance, if the coring distance is large, the ejection distance can be increased to reduce the inclination angle of the inclined actuator, so that the inclined push rod ejection is stable and reliable, and the wear is small.

When the size of the square iron is larger, in order to improve the strength and rigidity of the mold, sometimes the width of the square iron should be increased; Secondly, in order to improve the stability and reliability of the plastic parts launched, the push rod fixing plate should be guided by the guide column.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

The trapped air adjustment of the mold is difficult, and the deformation and the bottom row position pulling mold treatment method of the face shell

2025-08-12

The trapped air adjustment of the mold is difficult, and the deformation and the...

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrough, Market Reconstruction and Ecological Dimension Upgrade

2025-07-03

In-depth Deconstruction of the Injection Mold Industry: Technological Breakthrou...

Exhaust through the vent plug and vent valve of the mold

2025-10-18

Exhaust through the vent plug and vent valve of the moldOne: Exhaust through the...

Injection molds: Specialized manufacturing, empowering new quality productivity in the industry

2025-07-14

Injection molds: Specialized manufacturing, empowering new quality productivity ...

The innovative design and intelligent development trend of injection molds

2025-07-09

The innovative design and intelligent development trend of injection molds In...

Solutions to the problems of column bending deformation, delamination, surface peeling and frequent pressing of small spouts in the mold

2025-08-18

Solutions to the problems of column bending deformation, delamination, surface p...