Solutions for mold clamping lines, surface clamping marks and clamping position sticking to the mold

Solutions for mold clamping lines, surface clamping marks and clamping position sticking to the mold

The clamping wire of the mold

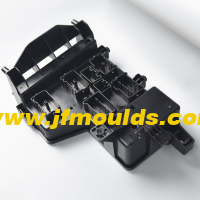

Phenomenon: Obvious wire clamping appears at the middle position of the top during the battery production process.

Analysis: Due to the mold design featuring four-point submersible injection of glue on both sides, the exhaust at the material flow convergence point is not smooth, resulting in trapped air and wire jamming.

Characteristics of injection molding machines

Grade: HT120T, Clamping force: 120t, plasticizing capacity: 152g

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: small water outlet, ejection method: Ejection by top block, mold temperature: 95°C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC GN-5001RFH, Color: Black, Product weight (single piece) : 0.67g, spout weight: 18.04g

(4) Analysis of causes of defects

When filling with glue at a fast material flow rate, due to the influence of the product structure, at the middle of every two glue entry points, the exhaust at the middle fusion point at the end of the material flow is not smooth, resulting in trapped air and wire jamming.

(5) Countermeasures

1. Use low modulus temperature and multi-stage slow filling injection.

2. In light of the product structure and the glue flow situation, the three-stage injection is adjusted. The mold temperature is adjusted and appropriately reduced, and a slower injection speed is used to allow the molten material to flow and fill slowly, thereby improving the severe gas trapping and wire jamming phenomenon of the product.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

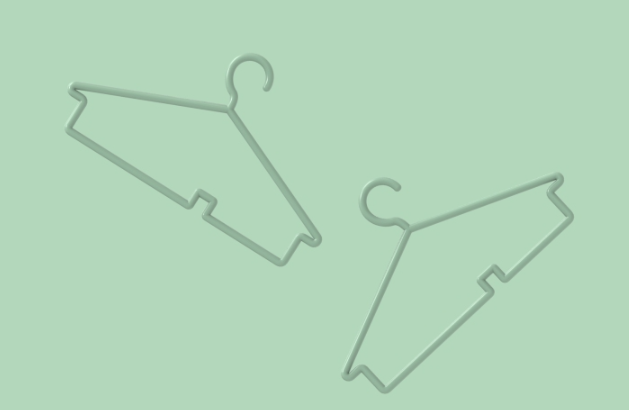

The surface indentation of the mold

Reason: Structural defect of the product

Analysis: The mold temperature is relatively low. The temperature of the molten glue is too low.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 100g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: lap gate, ejection method: Ejection by ejector pin, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: ABS 727, Color: natural color, Product weight (single piece) : 2.1g, sprue weight: 4.3g

(4) Analysis of causes of defects

Structural defects in the mold and excessive inserts have led to poor glue flow.

(5) Countermeasures

Adjust the oil temperature and the temperature of the molten glue to appropriately adjust the indentation to the lightest state.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

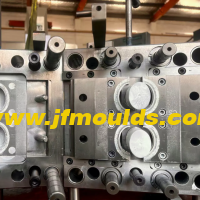

The clamping position of the mold is stuck to the mold

Analysis: The buckle is too small and too deep. The holding pressure time is too short and the pressure is too low.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 100g

(2) Mold characteristics

Mold ejection number: 1×8, injection method: lap gate, ejection method: Ejection by ejector pin, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: ABS 758, Color: Black, Product weight (single piece) : 0.3g, spout weight: 6.1g

(4) Analysis of causes of defects

The main flow of the mold is quite large, and the glue inlet method is submersible glue inlet. The molten material flows to the vicinity of the glue inlet. Due to the uneven thickness of the glue level, the raw material cannot evenly fill the mold cavity.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, for the second section, fill it slowly and in a very small position near the glue inlet. The third section should be filled rapidly to 90% of the mold cavity to prevent the high-temperature molten rubber from cooling. The fourth section should be filled slowly to ensure that all the air inside the mold cavity is completely expelled, avoiding adverse phenomena such as trapped air and charring. Finally, switch to the pressure-holding switching position.

Related News

Exhaust through the vent plug and vent valve of the mold

2025-10-18

Exhaust through the vent plug and vent valve of the moldOne: Exhaust through the...

Solutions for air marks at the water outlet position of the mold and drag damage at the water outlet position of the battery frame

2025-08-27

Solutions for air marks at the water outlet position of the mold and drag damage...

The dimensional tolerance of injection mold fit and the surface roughness of mold parts

2025-09-12

The dimensional tolerance of injection mold fit and the surface roughness of mol...

Injection molds: From millimeter-level precision to the invisible engine of industrial transformation

2025-07-07

Injection molds: From millimeter-level precision to the invisible engine of indu...

Thread demolding

2025-11-17

Thread demolding(1) Forced demolding of the thread The mold structure of th...

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...