Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in molds

Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in molds

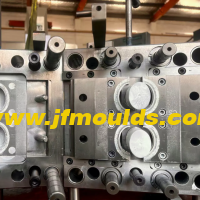

The pin of the mold's buckle position

Analysis: The buckle is too small and too deep. The gap of the buckle insert is too large.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 100g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: lap gate, ejection method: Ejection by ejector pin, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: ABS 727, Color: natural color, Product weight (single piece) : 2.3g, sprue weight: 4.1g

(4) Analysis of causes of defects

The large gap between the mold inserts causes the flash to run during injection molding.

(5) Countermeasures

Reduce the injection molding pressure.

2. Redo the inserts.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The buckle of the mold has shrunk

Reason: The glue position is too thick, resulting in the glue flow not being fully filled.

Analysis: The gate is too far from the thick glue position. The thickness of the glue position is inconsistent. The holding pressure is too short.

Characteristics of injection molding machines

Grade: DEMAG, clamping force: 100t, plasticizing capacity: 100g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: lap gate, ejection method: Ejection by top block, mold temperature: 100°C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC 2010, Color: Black, Product weight (single piece) : 2.1g, spout weight: 7g

(4) Analysis of causes of defects

The main channel of the mold is quite large. The method of injecting glue is submersible. The molten material flows to the area near the glue inlet. Due to the uneven thickness of the glue level, the raw material cannot evenly fill the mold cavity.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the runner opening to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. In the third section, fill 90% of the mold cavity quickly to prevent the high-temperature molten glue from cooling. In the fourth section, fill the mold cavity slowly to completely expel the air inside the mold cavity and avoid trapped air and burning and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Trapped gas fracture in the mold

Phenomenon: At the convergence point of the two streams of glue, trapped air causes wire clamping.

Characteristics of injection molding machines

Grade: Haitian, Clamping force: 120t, Plasticizing capacity: 163g

(2) Mold characteristics

Mold ejection number: 1×2, injection method: direct injection into the gate, ejection method: push plate ejection, mold temperature: 80°C (constant temperature machine)

(3) Product characteristics

Material: ABS+PC, Color: Gray, Product weight (single piece) : 8g, nozzle weight: 4g

(4) Analysis of causes of defects

The surface of the mold (rear mold) is not vented. Due to the product structure having a square frame, when a certain amount of material is injected into the mold cavity in parallel by the injection molding machine, it becomes two streams of flow. During the connection, the gas generated cannot be discharged in time, and the surface of the product connection will be trapped with gas, resulting in poor connection and product breakage.

(5) Countermeasures

Exhaust systems are installed at the corresponding positions where trapped gas is generated on the mold to expel the gas within the rubber compound.

Related News

Exploring Injection Molds: Unlocking the Core Code of Plastic Molding

2025-07-10

Exploring Injection Molds: Unlocking the Core Code of Plastic Molding In the ...

Solutions to the problems of hard rubber indentation, row position demolding and inconsistent product dimensions in molds

2025-08-29

Solutions to the problems of hard rubber indentation, row position demolding and...

Design of Injection mold gating system

2025-10-20

Design of Injection mold gating system The injection system of an injection...

The coordinated evolution of technological iteration and industrial ecosystem

2025-07-15

The coordinated evolution of technological iteration and industrial ecosystemI. ...

The selection of mold base specifications and models

2025-09-28

The selection of mold base specifications and models(1) Selection of two-plate m...

Injection molds: The hidden champions in industrial manufacturing

2025-07-14

Injection molds: The hidden champions in industrial manufacturing In the vast...