Design of the external dimensions of mold-formed parts

Design of the external dimensions of mold-formed parts

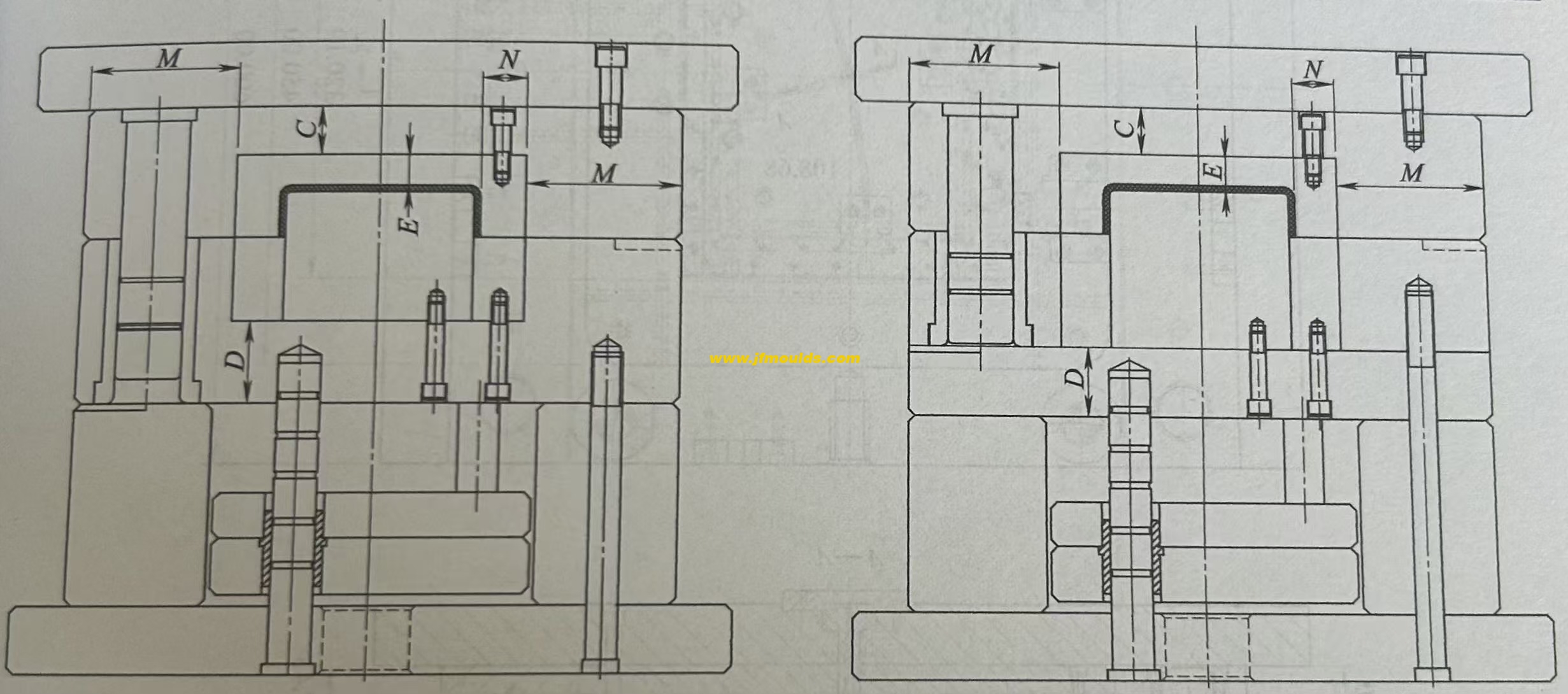

According to the external dimensions of the plastic part (including the projected dimensions and height 0 on the parting surface) and the structural characteristics (whether lateral drawing is required)

The core can determine the external dimensions of the inner mold insert. Once the dimensions of the inner mold insert are determined, the dimensions of the mold base can be roughly determined.

Trash can mold Manufacturer in China (jfmoulds.com)

The data is only for reference in the general structural design of injection molds. The following should be noted in the actual design process

What time

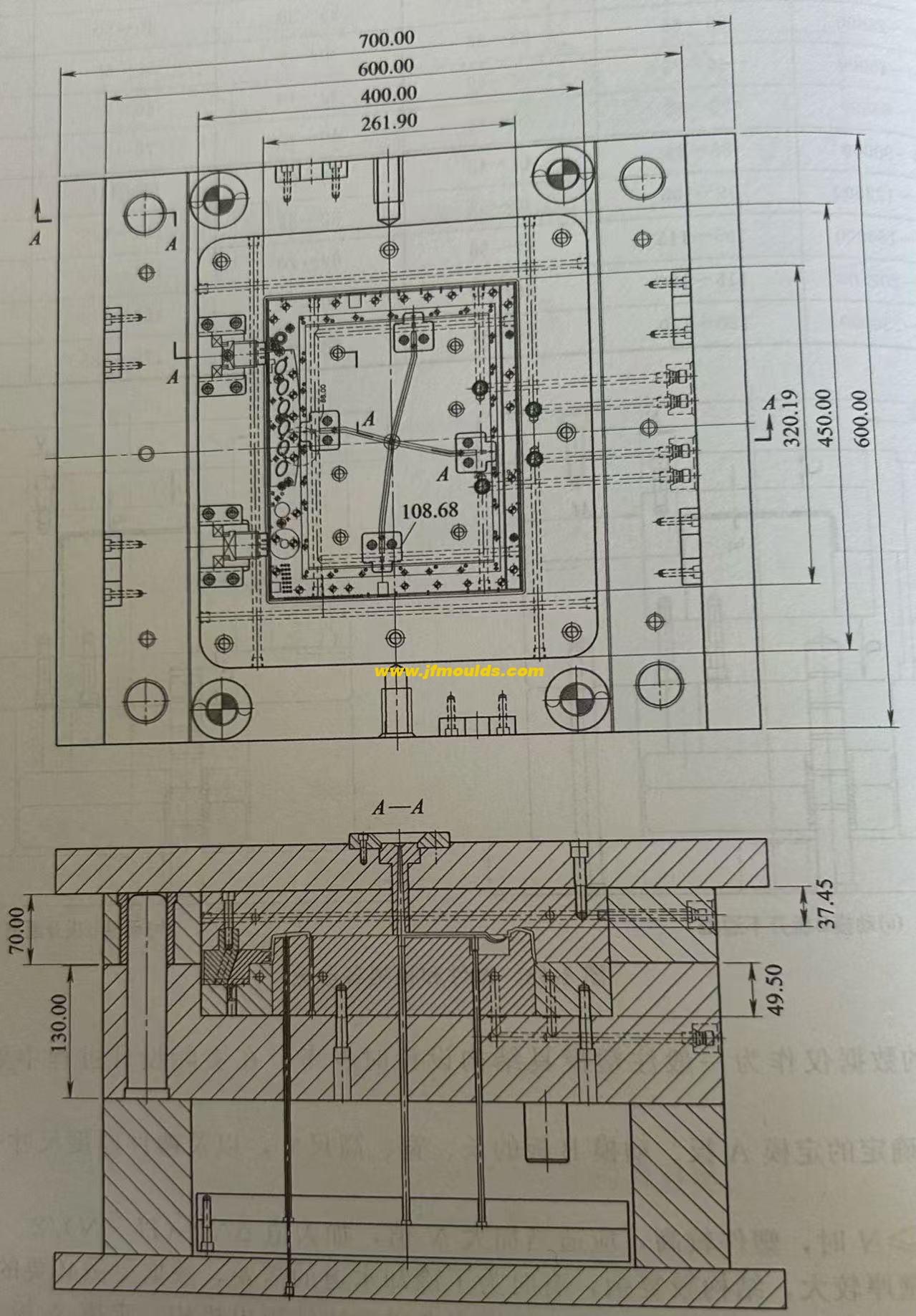

The final determined dimensions of the length, width and height of the fixed mold A plate and the moving mold B plate, as well as the thickness of the inserts, must be taken as standard values.

When H is N, the plastic part is relatively high, and the N value should be appropriately increased. The increase value AN= (H - N)/2.

③ The wall thickness of the plastic part is relatively large and the structure is rather complex. Sometimes, to meet the requirements of the cooling water channels, necessary adjustments need to be made to the data.

④ The structure of the plastic part is complex. The mold has A lateral core-pulling mechanism or requires a special ejection mechanism. The length, width and height dimensions of the fixed mold A plate and the moving mold B plate all need to be increased accordingly. For those with sliders sliding, the length or width is generally increased by 50mm, 100mm or 150mm depending on the size of the slider, and the thickness is increased by 10mm or 20mm.

For straight molds without A panel, the thickness of the A plate can be increased by 5 to 10mm on the basis of the above, and then the standard value can be taken.

After basically determining the specifications, models and dimensions of the mold base, the overall structure of the mold base should also be verified to check whether the determined mold base conforms to the injection molding machine given by the customer, including the external dimensions of the mold base, the maximum opening stroke, the ejection method and the exit stroke, etc.

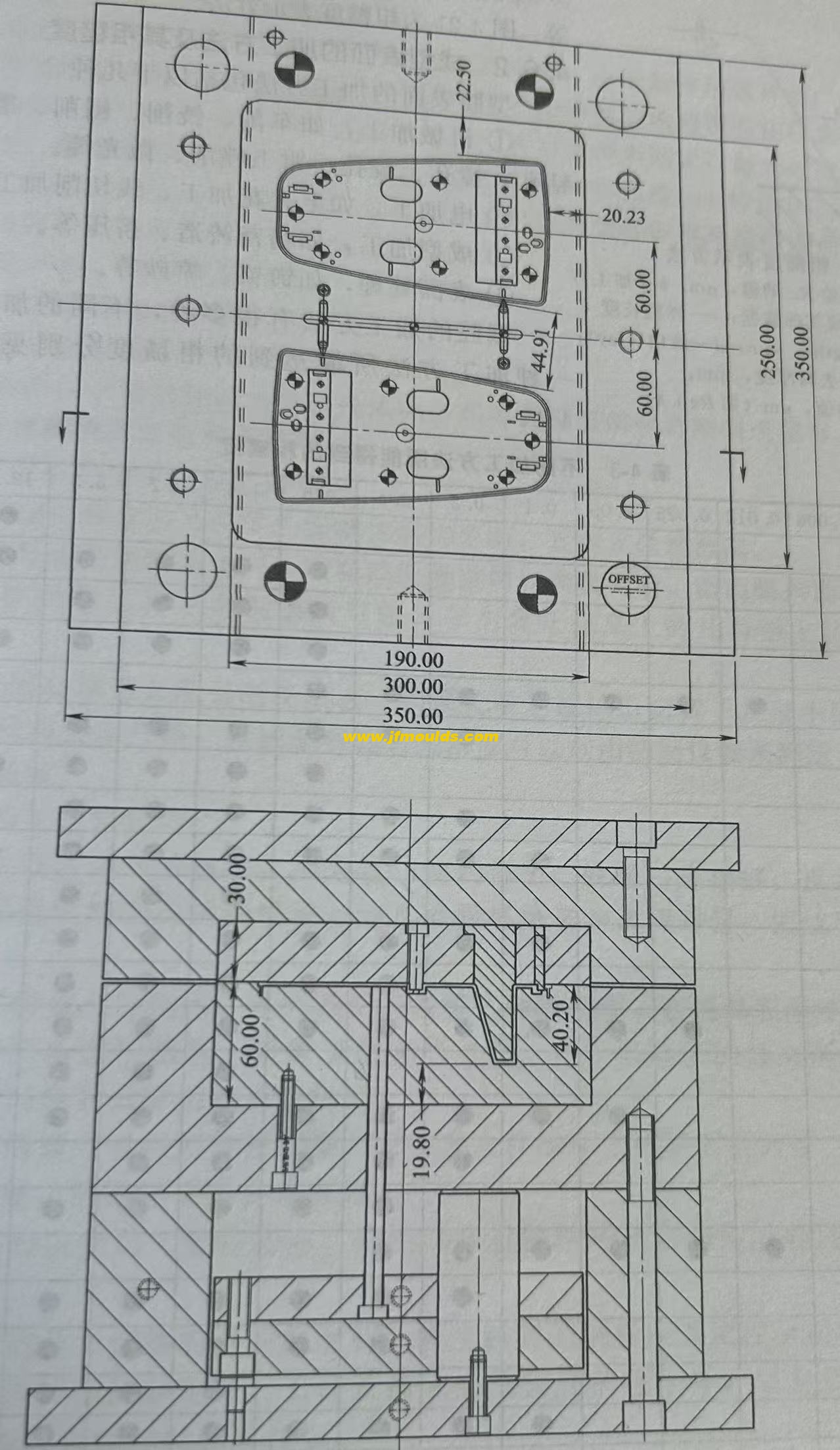

Example 1: Positioning of single-cavity molds. For single-cavity molds, the projected area is the product of the maximum length and width dimensions of the plastic part on the parting surface, and also includes the area of the through hole in the middle. For a single-cavity mold arrangement example, the projected area of the plastic part on the parting surface is :140.2×112.1= 15,716.42mm. Referring to Table 4-2, we get: M=55-65, N=32-36, C-30-35, D-50-60,E-30-34. Due to the irregular shape of the plastic part, the number of N was adjusted as necessary.

Example 2: Positioning of multi-cavity molds. For multi-cavity molds, the projected area is the total length of each cavity on the parting surface after its arrangement

Multiply by the total width, including the through holes of each cavity and the area between each cavity. Figure 4-20 shows an example of multi-cavity mold positioning, with a projected area of

199X134= 26,666mm ², M=65-75, N=36-40, C=35-40, D=60-75,E=34-38.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

Types and basic requirements of mold design drawings

2025-09-07

Types and basic requirements of mold design drawingsTo shorten the production cy...

The structure, materials and design of injection molds

2025-07-18

The structure, materials and design of injection molds In the vast landscape ...

Injection molds: The Cornerstone of Precision Manufacturing and New Trends in Industry Development

2025-07-08

Injection molds: The Cornerstone of Precision Manufacturing and New Trends in In...

The surface of the mold is baked and printed bright and has surface flow marks

2025-08-02

The surface of the mold is baked and printed bright and has surface flow marksTh...

Cooling control of the mold

2025-07-23

Cooling control of the mold1.Cooling pipe The function of the cooling pipe is...