The structure, materials and design of injection molds

The structure, materials and design of injection molds

In the vast landscape of modern industrial manufacturing, injection molds are like a low-key yet crucial unsung hero, quietly supporting the large-scale and high-quality production of plastic products. From the bottles and jars in daily life and the shells of electronic devices to automotive parts and precision components in aerospace, injection molds are everywhere. With precise design and outstanding manufacturing techniques, they transform designers' creativity into practical and exquisite plastic products, profoundly influencing all aspects of people's lives.

1.The structure and working principle of injection molds

Injection molds are like precise industrial castles, composed of multiple key parts working together, each of which shoulders a unique and indispensable mission. The forming device, as the core area, the die and the punch are like two dancers in perfect harmony, precisely cooperating to give the plastic products the final shape and size. The smoothness and precision of its surface directly determine the appearance quality and performance of the product. The guide pins and guide sleeves in the positioning device are like loyal guards, ensuring that the mold maintains an accurate positional relationship during opening and closing, avoiding deviations, and safeguarding the stability of the injection molding process. Fixed devices such as I-beams and mold pits firmly secure the mold to the injection molding machine, ensuring it remains motionless even under strong pressure and guaranteeing production safety. The cooling system is like the blood circulation system of the human body. Through the ingeniously designed water transport holes, the coolant circulates in the mold, quickly taking away the heat generated during the injection molding process, enabling the plastic products to cool and set rapidly, and improving production efficiency. The heating tubes and heating wires in the constant temperature system play a role when necessary to maintain the temperature stability of the mold and meet the molding requirements of special plastic materials. The nozzle holes, runner slots and runner holes of the runner system are the highways for the flow of molten plastic, guiding the plastic to fill every corner of the mold cavity evenly and quickly. The ejector pins and ejector rods of the ejection system, after the plastic products have cooled and formed, act like gentle pusher hands, smoothly pushing the products out of the mold cavity and completing one injection molding cycle.

The working process of injection molds is like a wonderful symphony performance, with each link closely connected and proceeding in an orderly manner. When the injection molding machine starts, the moving and fixed molds of the mold, like two close partners, quickly close to form a sealed cavity, marking the beginning of the injection molding journey. Meanwhile, plastic particles gather in the hopper of the injection molding machine and are then sent into the heating device. Under the effect of high temperature, they gradually change from solid to viscous liquid, like living spirits, full of vitality. The molten plastic, driven by the screw, rushes into the mold cavity at an extremely high speed and pressure along the runner system, instantly filling every space, as if it were a fierce charge battle. After the filling is completed, the pressure-holding stage immediately begins. The continuous pressure acts as a steadfast guardian, ensuring that the plastic products remain dense and precisely sized during the cooling and shrinking process, and avoiding defects such as voids or deformations. With the efficient operation of the cooling system, the heat inside the mold is rapidly carried away, and the plastic products gradually cool and solidify, as if awakening from a deep sleep, gradually acquiring a stable shape and performance. When everything is ready, the mold slowly opens and the ejection system starts to work, gently pushing the formed plastic products out of the mold. What awaits them is the subsequent processing and inspection steps, while the mold takes a brief rest to prepare for the next round of injection molding challenges.

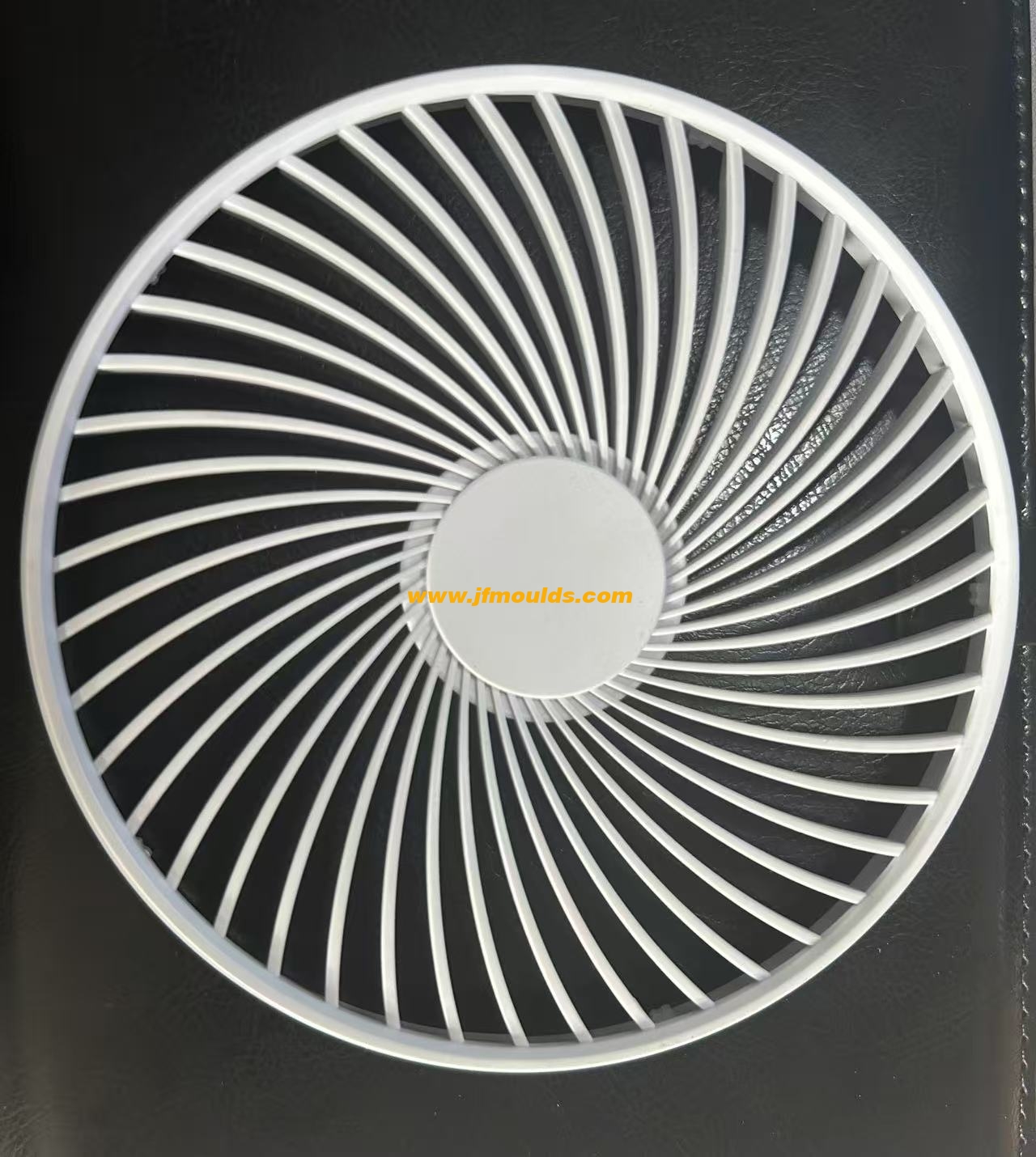

Fan mold Manufacturer in China (jfmoulds.com)

2. Material selection for injection molds

In the manufacturing process of injection molds, material selection is undoubtedly one of the most crucial steps, much like choosing the right foundation stones for a grand building, which directly affects the performance, lifespan and manufacturing cost of the mold. Mold steel, as the main material for molds, comes in a wide variety of types, each with its own characteristics. Each type demonstrates unique advantages in different application scenarios.

P20 steel is a frequent guest in the field of mold manufacturing and is highly favored for its excellent comprehensive performance. Its hardness is moderate and it can be processed in the pre-hardened state. It has good processing performance and can meet the molding requirements of most plastic products. Meanwhile, P20 steel has certain wear resistance and corrosion resistance, which to a certain extent ensures the service life of the mold. It is often used to manufacture injection molds for toys, daily necessities and other products where the requirements for precision and surface quality are relatively low.

718 steel is an optimized and upgraded version of P20 steel. It has higher hardness, better wear resistance and polishing performance. After undergoing a special heat treatment process, the internal structure of 718 steel becomes more uniform and fine, enabling it to maintain better dimensional stability and higher processing accuracy during processing. Therefore, 718 steel is often used in the manufacturing of precision electronic components, automotive interior parts and other injection molds with high requirements for surface quality and accuracy, which can provide these products with a mirror-like smooth surface and precise dimensions.

H13 steel stands out for its outstanding thermal strength and thermal fatigue resistance, making it a top performer among hot work die steels. In high-temperature environments, H13 steel can maintain stable mechanical properties, is not prone to deformation or softening, and can withstand repeated thermal shocks and mechanical stresses. Therefore, it is widely used in the manufacturing of high-temperature injection molds for automotive engine blocks, wheels and other components, as well as die-casting molds and other fields, providing a reliable guarantee for the production of these high-performance products.

In addition to mold steel, in some special circumstances, other materials are also selected to manufacture injection molds. For instance, for some small-batch produced or trial-made products, in order to cut costs, aluminum alloy materials might be adopted. Aluminum alloy has the advantages of low density, light weight and good processing performance, which can quickly manufacture molds to meet the short-term production needs of products. For some occasions where the precision and surface quality of plastic products are extremely high, such as optical lens molds, high-performance materials like beryllium copper alloys may be selected. Beryllium copper alloy has excellent thermal conductivity, wear resistance and dimensional stability. It can quickly transfer heat while ensuring the accuracy of the mold, improve production efficiency, and provide an ideal solution for the production of high-precision plastic products.

Trash can mold Manufacturer in China (jfmoulds.com)

3. Key points of injection mold design

The design of injection molds is a comprehensive art and science. It requires designers to fully consider multiple factors such as the shape, size, and precision requirements of the product, as well as the characteristics of plastic materials and parameters of injection molding processes. Only by carefully planning and ingeniously arranging can efficient and high-quality injection molds be created.

When designing a mold, the first step is to determine the number and layout of the cavities. The selection of the number of cavities requires a comprehensive consideration of factors such as the production batch of the product, the specifications of the injection molding machine, and the manufacturing cost of the mold. If the production batch is large, multi-cavity molds can be adopted to enhance production efficiency and reduce production costs. However, if the precision requirements for the product are high or the clamping force of the injection molding machine is limited, it may be necessary to choose a single-cavity mold to ensure the quality of the product. The layout of the cavity needs to follow the principle of balance to ensure that the molten plastic can be evenly filled into each cavity, avoiding problems such as uneven filling and pressure imbalance. Generally speaking, the layout of the cavity can adopt symmetrical distribution, circular distribution or rectangular distribution, etc. The specific choice should be determined based on the shape of the product and the structure of the mold.

The design of the gating system is one of the key links in injection mold design, which directly affects the flow performance and filling effect of the molten plastic. The gating system mainly consists of the main runner, the runner, the gate and the cold material cavity, etc. The main runner is the entrance for molten plastic to enter the mold. Its size and shape need to be determined based on the nozzle size of the injection molding machine and the fluidity of the plastic to ensure that the plastic can smoothly enter the runner. The distribution channel is responsible for evenly distributing the plastic in the main channel into each cavity. Its cross-sectional shape and size need to be optimized based on factors such as the type of plastic, the number and layout of cavities, in order to reduce pressure loss and heat dissipation. The gate is the most crucial part of the gating system. Its size, shape and position directly affect the filling speed of the plastic, pressure distribution and the quality of the product. Common gate forms include side gates, point gates, and hidden gates, etc. Each type of gate has its own advantages, disadvantages, and applicable scope. Designers need to make reasonable choices based on the characteristics and requirements of the products. The cold material cavity is used to collect the cold material generated during the injection molding process to prevent it from entering the cavity and affecting product quality.

The design of the ejection system is also an indispensable part of injection mold design. Its function is to smoothly eject plastic products from the mold cavity after they have cooled and formed. The design of the ejection system needs to take into account factors such as the shape, size, wall thickness of the product and the structure of the mold, and select the appropriate ejection method and ejection components. Common ejection methods include ejection with ejector pins, ejection with tubes, and ejection with push plates, etc. Each ejection method has its own applicable scope and advantages and disadvantages. The layout and quantity of the ejection components need to be reasonably designed based on the force conditions and ejection resistance of the product to ensure that the product can be evenly stressed and ejected smoothly, avoiding problems such as white ejection and deformation.

The design of the cooling system is of great significance for improving the efficiency of injection molding production and product quality. The function of the cooling system is to quickly remove the heat generated during the injection molding process by circulating the coolant, enabling the plastic products to cool and set rapidly. The design of the cooling system needs to take into account factors such as the structure of the mold, the shape and size of the plastic products, and the thermal properties of the plastic, and rationally arrange the position, quantity and diameter of the cooling pipes. The layout of the cooling pipes should be as close as possible to the mold cavity to enhance cooling efficiency, but at the same time, interference with other mold components should also be avoided. In addition, it is necessary to select the appropriate coolant and cooling method, such as circulating water cooling and chilled water cooling, to meet the cooling requirements of different products.

Related News

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

Focus on quality and deeply cultivate innovation

2025-07-05

Focus on quality and deeply cultivate innovation In daily life, from the mobi...

Solutions for delamination, peeling, hardening and fragility of injection-molded products

2025-08-01

Solutions for delamination, peeling, hardening and fragility of injection-molded...

A Comprehensive Guide to Injection Molds: From Basics to Applications

2025-07-11

A Comprehensive Guide to Injection Molds: From Basics to Applications In the vas...

From technological breakthroughs to intelligent transformation

2025-07-07

From technological breakthroughs to intelligent transformation Injection mol...

Cooling control of the mold

2025-07-23

Cooling control of the mold1.Cooling pipe The function of the cooling pipe is...