Cooling control of the mold

Cooling control of the mold

1.Cooling pipe

The function of the cooling pipe is to transfer the heat in the mold to the temperature-controlled medium through the side walls of the pipe. The temperature control method with the highest performance-to-performance ratio is to use circular cooling pipes for temperature reduction.

Each injection molded part should have its own cooling pipe. There are the following general rules for choosing cooling pipes:

The diameter of the channel is usually 6 to 14 millimeters.

Multiple small-diameter pipes are more effective than a few large-diameter ones.

Pipes with small diameters but long lengths can cause significant pressure losses.

Series cooling pipeline

When using series cooling, there is only one pipe for entering and leaving the mold. As a result, the temperature of the cooling medium will gradually increase as the pipeline extends. In this way, the temperature of the mold in different areas will be different.

Parallel cooling pipeline

By using this cooling method, the incoming water will be divided into multiple parallel pipes to achieve the purpose of uniform control of the mold temperature. The disadvantage of this method is that if there is a pipe blockage, its location is very difficult to determine.

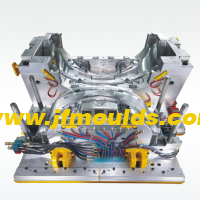

Car bumper mold Manufacturer in China (jfmoulds.com)

2. Temperature distribution

The temperature of the mold is crucial for both the economic benefits of injection molding and the quality of the injection molded parts. The latest research results show that the temperature difference of the entire cavity should not exceed 5℃. This goal can be achieved by correctly applying a series of cooling methods.

In the early days, the temperature difference between the inlet and outlet of the mold often exceeded 20℃. This will lead to a decline in the quality of injection molded parts and an extension of the cooling time required for the melt to solidify, and the corresponding molding cycle will also be prolonged. Nowadays, the mold temperature control design has become a selectable heating mode, that is, heating close to the product surface and can be controlled in different areas.

There are various cooling methods that can quickly bring the mold to the demolding temperature of the product. Simply put, there are continuous cooling, segmented cooling, and intermittent cooling, also known as pulse cooling.

It is very important to remove heat under the premise that the mold temperature is appropriate. When the mold temperature is too low, rapid cooling will have a negative impact on the product performance.

The distribution of temperature and the fluidity of plastic should both be taken into consideration.

2.1 Temperature distribution of thermosetting plastic molds

Thermosetting plastic molds are electrically heated and are made up of heating rods, heating plates, heating coils or heating plates. The hot plate is not integrated into the mold but is part of the injection molding machine. The temperature of the mold is between 150 and 180 degrees Celsius.

The mold temperature is measured by a thermocouple. Thermocouples and heating elements are configured to keep the surface temperature difference within 5℃. When the requirements for injection molded products are very high, the temperature difference needs to be reduced from 5℃ to 2℃.

To reduce heat loss from the mold, heat insulation boards should be installed on the mold.

2.2 Temperature distribution of elastomer molds

Elastomer molds are also electrically heated and are composed of heating sleeves, heating plates, heating coils or heating plates. The hot plate is not integrated into the mold but is part of the injection molding machine. The heat output of thermosetting plastic molds is 35 to 40W/kg, while that of elastomer molds requires 50 to 60W/kg. The reason is that the elastomer has a relatively low thermal conductivity, and secondly, its product structure is relatively weak, so it cools down quickly.

The temperature of the elastomer mold is also measured by thermocouples. Thermocouples and heating elements are configured to keep the surface temperature difference within 5℃. When the requirements for injection-molded products are very high, the temperature difference can be as low as 2 to 5 degrees Celsius.

To reduce heat loss from the mold, heat insulation boards should be installed on the mold.

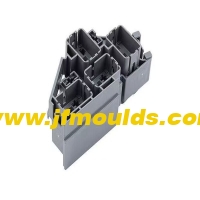

Bucket mold Manufacturer in China (jfmoulds.com)

3. Continuous cooling

The temperature control of the mold requires the use of a cooling medium, which will directly penetrate the mold. However, most injection molds are heated to 40 to 80 degrees Celsius by mold temperature control units. The mold temperature for engineering plastics needs to be as high as 200℃.

The cooling water flow regulator uses manual flow regulation to control the temperature. The thermometer responds to temperature changes by measuring the temperature of the return water. The regulation of flow is accomplished by the control valve.

The flow rate display is indicated by a conical float lifted by the water flow in the mold cooling circuit after passing through a complex measurement system.

Mold temperature control machine

The temperature control medium in the mold temperature control machine is water or oil. If the required temperature is higher than the boiling point of water, a pressurized water temperature machine or an oil temperature machine should be used.

The water flow loop in a traditional mold temperature control machine can be either open-loop or closed-loop. In an open-loop system, indirect cooling is used, and the pre-water temperature can reach 95°C while the oil temperature can reach 200 °C. To avoid contact with oxygen, oil is usually only used in closed-loop systems. In a closed-loop system, the system water temperature can reach as high as 230℃.

If the cooling medium cannot directly reach all areas of the formed component, the cooling time needs to be extended to ensure that the temperature of the uncooled parts also reaches the temperature required for demolding. This will lead to an extension of the molding cycle and an increase in product costs. Therefore, all components on the mold must be integrated into the cooling circuit.

4. Zoned cooling

The basis of zonal cooling is the mold design based on the heat distribution of the product. The mold is divided into independent areas so that areas with different temperature requirements can be assigned to independent cooling circuit control.

The traditional zoned cooling solution, also known as the multi-loop cooling method, connects independent cooling loops to independent mold temperature control units. When the number of cooling circuits increases, both the operational difficulty and the required space will increase.

Zoned cooling enables different injection molded parts to be cooled separately. When the plastic flow path is long, the area near the gate can be focused on cooling, while gradually moving away from the gate, the cooling amplitude can be gradually weakened. Separate control of different temperature zones can balance the cavity temperature. As a result, the quality of injection molded parts is improved, while the molding cycle is reduced. Temperature control circuits of the same temperature can be aggregated together to reduce operational difficulty.

The cooling of strip-shaped and slender cores is particularly difficult. A makeshift solution is to use mold materials with high thermal conductivity in these areas. For instance, wrinkled copper has a thermal conductivity five times higher than that of steel.

Related News

Standard parts of molds

2025-07-24

Standard parts of molds1 Mold framePrefabricated standard mold base assemblies o...

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

The screw columns of the mold are prone to damage and weld marks/shrinkage

2025-08-07

The screw columns of the mold are prone to damage and weld marks/shrinkageThe sc...

Injection mold commonly used six kinds of mold materials

2025-06-19

The choice of steel not only affects the service life of the mold, but also affe...

The causes and solutions of bubbles, mold sticking and gate sticking in injection molded products

2025-07-31

The causes and solutions of bubbles, mold sticking and gate sticking in injectio...

A collection of mold manufacturing processes, standards, processes and cases.

2025-06-19

The process flow chart is as follows: all kinds of tools and products used in ou...