The mold case integrates lines and exposed white

The mold case integrates lines and exposed white

Mold fusion line:

Phenomenon: There are fusion lines on the razor's outer shell and blade holder.

The reason is that due to the product structure, the glue position at this location is too thin, resulting in a melt flow point and a fusion mark.

Analysis: The position setting of the molten adhesive is not precise enough. The setting of the injection speed is not precise enough. The temperature at which the glue is melted and dissolved is insufficient.

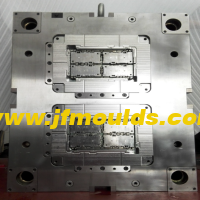

(1)Characteristics of injection molding machines

Grade: Demag (Jiangsu), clamping force: 100t, Plasticizing capacity: 94g

(2) Mold characteristics

Mold ejection number :1x2, glue feeding method: small water outlet to large water outlet, ejection method: Ejection by ejector pin. Mold temperature :90℃(constant temperature machine)

(3) Product characteristics

Material: ABS PA757 37826, Color: grey, Product weight (single piece) : 5.39g, Spout weight: 4.32g

(4) Analysis of causes of defects

1.The flowability of the raw materials used in the product is slightly worse than that of other raw materials.

2. During the product's molding process, the precision requirements for various process parameters such as position, speed, and calibration are relatively high, and they need to be set very preciselyAccurate.

3. The temperature setting is unreasonable.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position, and then use the second section Just fill it slowly and in a very small position near the glue inlet. The third section fills 70% of the mold cavity at medium speed to allow the glue flow to pass through the product Where the meat is thin, avoid the molten rubber compound from converging there. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity Avoid adverse phenomena such as trapped gas and burning. Finally, switch to the pressure-holding switching position.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Injection molding process table

| Injection molding machine: Haitian 160T, Type A screw, injection volume: 250g | Product Name: Razor Housing |

| Raw material: ABS PA757 | Colour: Black | Drying temperature: 85°C | Drying method: Dehumidifying dryer | Drying time :2.5 hours | Recycled material usage: 0 |

Finished product weight: 27.1g×2=54.2g | Nozzle weight: 7.6g | Mold output: 1×2 | Gate injection method: Point gate |

| Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | Front mold | Constant temperature machine | 90°C | 88°C |

| 240°C | 235°C | 230°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | Rear mold | Constant temperature machine | 90°C | 83°C |

| △ | △ | △ | △ | △ | ||||

| / | 80 | 90 | Holding pressure | Pressure-holding position | 100 | 100 | 110 | 130 |

|

| / | 1.5 | 2.5 | Holding pressure time | "End | 8 | 8 | 35 | 40 |

|

| Residual amount of injection glue | / | / | / | / | 15 | 33.6 | 47 |

| |

| 7.8 | / | / | / | / | 3.7 | / | / | / |

|

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 3.7 | 14 | 35 | 5 | 10 15 10 | 10 | 55 | 3 |

Mold closing time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 100 | 40 | 1 | 15 35 38 | / | / |

The mold shows white:

Phenomenon: The decorative parts on the bottom shell of S28 show white.

Reason: This is an IML product. After the material is silk-screened and then placed in the mold for injection molding, due to the inconsistency between the unfolded area of the sheet and the area of the front mold core, poor edge wrapping occurs, resulting in a white exposure phenomenon.

Analysis: The projected area of the sheet material is inconsistent with that of the mold. When hot-pressing and punching sliced materials, there is a deviation.

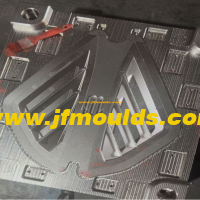

(1)Characteristics of injection molding machines

Grade: DEAMG (Ningbo), Clamping force :50t, plasticizing capacity :42g

(2) Mold characteristics

Mold ejection number :1x2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 70℃(constant temperature machine)

(3) Product characteristics

Material: PMMAIRK304, Color: Transparent, Product weight (single piece) : 2.4g, nozzle weight: 8.2g

(4) Analysis of causes of defects

1.The projected area of the sheet material is inconsistent with that of the mold.

2. Deviation occurs when hot-pressing and punching sliced materials.

3. When placing the sheet material, the technique was not standard and it was placed off-center.

(5) Countermeasures

1.Increase the projected area of the sheet material.

2. Adjust the hot-pressing punching die.

3. Add positioning brackets for shaping.

Injection molding process table

| Injection molding machine: DEMAG 50T ,type B screw injection ,capacity 42g | Product Name: Decorative Piece |

Raw material: PMMA IRK304 | Color: Transparent | Drying temperature: 80°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 2.4g×2=4.8g | Nozzle weight: 8.2g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 62°C |

| 262°C | 250°C | 242°C | 236°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 601°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |  Injection pressure Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Standard parts of molds

2025-07-24

Standard parts of molds1 Mold framePrefabricated standard mold base assemblies o...

The positioning ring and screws of the mold

2025-10-07

The positioning ring and screws of the moldOne: Positioning circleThere are two ...

The drawing of the mold and the inking of the gate

2025-08-05

The drawing of the mold and the inking of the gateMold drawing Phenomenon: Th...

How to solve the problems of surface dents and mold on injection molds

2025-08-05

How to solve the problems of surface dents and mold on injection moldsConcave po...

Classification of injection molds

2025-09-06

Classification of injection moldsDifferent types of molds have different require...

From principle to application, understand this "shaping master" in industry

2025-07-16

From principle to application, understand this "shaping master" in industry P...

Injection velocity

Injection velocity Velocity of fire position

Velocity of fire position Injection time

Injection time