The surface baking printing and light and shadow of the mold

The surface baking printing and light and shadow of the mold

Surface baking and printing:

Phenomenon: During the production process of the product, whitening and baking marks often appear on the surface.

Analysis: The surface temperature setting of the mold is unreasonable. The cooling time of the mold surface texture is too short, causing the product to shrink. The pressure setting in the fourth section is too low.

(1)Characteristics of injection molding machines

Grade: Haitian, Clamping force :120t, Plasticizing capacity :152g

(2) Mold characteristics

Mold ejection number :1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 76 ° C (constant temperature machine)

(3)Product characteristics

Material :ABS, Color: Black. Product weight (single piece) : 42.6g, sprue weight :7.3g

(4)Analysis of causes of defects

1. The main runner of the mold is thin and long. The method of feeding the molten material is point-in feeding. Due to the slow speed and pressure, the molten material flows near the feeding port

The force is large, causing an increase in product stress and obvious baking marks.

2. The mold temperature is set too low for the front mold and too high for the rear mold.

3. The pressure at the end and the cycle time are unreasonable.

(5)Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position, then proceed to the second section Just fill the area near the rubber inlet at a slow speed and in a very small position. In the third stage, fill 90% of the mold control with a medium pressure quickly to prevent the high-temperature molten rubber from cooling. In the fourth stage, fill the mold cavity slowly to completely expel the air inside the cavity. Finally, switch to the pressure-holding switch position.

3. By setting the mold temperature at 85 °C for the front mold and 73°C for the rear mold, the cooling time has been increased from the original 4 seconds to 47 seconds.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Injection molding process table

| Injection molding machine: Haitian 120T Type B screw injection capacity 152g | Product Name: Transparent Mirror |

| Raw material: ABS | Colour: Black | Drying humidity: 85°C | Drying method: Dehumidifying dryer | Drying time: 3 hours | Drying time: 3 hours |

| Finished product weight: 42.6g×2=85.2g | Nozzle weight: 7.3g | Mold output: 1×2 | Gate injection method: Point gate |

| Barrel temperature | Mold temperature | Use machines | "Settings | "Actual |

| 1 | 2 | 3 | 4 | 5 | "Actual | Water temperature machine | 85°C | 80°C |

| 245°C | 240°C | 235°C | 230°C | 220°C | ||||

| △ | △ | △ | △ | after | Water temperature machine | 73°C | 68°C | |

| △ | △ | △ | △ | △ |

| / | 73 | Holding pressure | Pressure-holding position | 87 | 90 | 92 | 98 |  Injection pressure Injection pressure | |

| / | 3 | Holding pressure time | 12 | 15 | 21 | 63 | 73 |  Injection pressure position Injection pressure position | |

| Residual amount of injection glue | / | 2.0 | / | 55 | 78 | 20 | 65 |  Injection velocity Injection velocity | |

| 7.8 | / | / | / | 15 | 21 | 63 | 73 |  Velocity of fire position Velocity of fire position |

| Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Rewind time |

| 1 | 4.3 | 47 | 69 | 3.7 | 50 55 18 | 13 | 85 | 3 |

| Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 830kN | 63 | 1 | 15 85 88 | / | / |

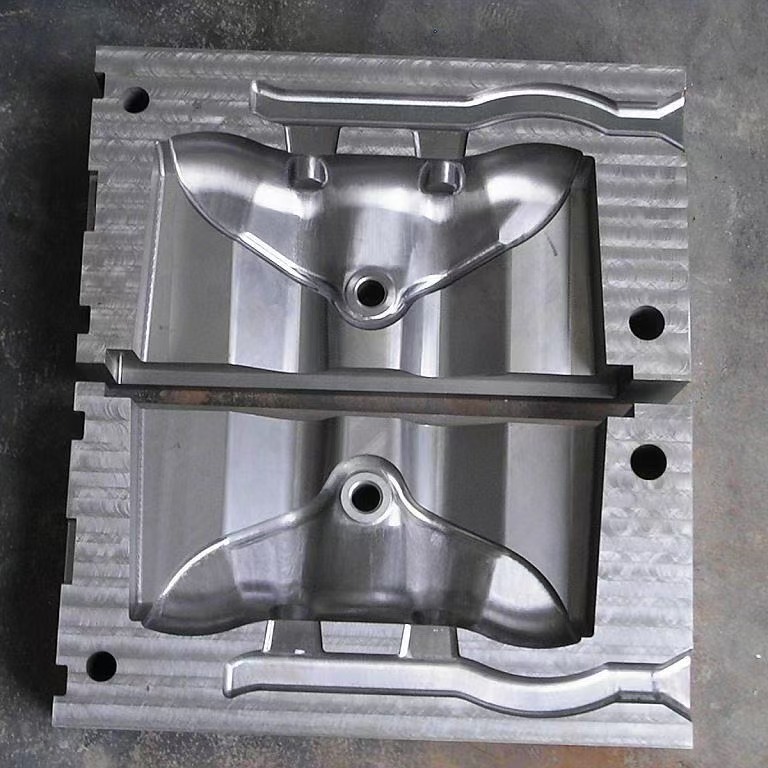

Light and shadow:

Phenomenon: During the production process of the shell, light and shadow are prone to occur at positions with structural differences and at a distance from the glue inlet.

Analysis: The thickness of the product meat is inconsistent. The differences in product cooling shrinkage and internal stress decomposition: The injection pressure and holding pressure are relatively small.

(1)Characteristics of injection molding machines

Grade: Haitian (Jiangsu), clamping force :160t, plasticizing capacity: 200g

(2)Mold characteristics

Mold ejection number :1x2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: Mold cavity 85℃ (constant temperature machine), rack row position 70℃ (constant temperature machine)

(3) Product characteristics

Material: ABS PA757 37784, Color: Black (fine texture surface), Product weight (single piece) : 27.1g, spout weight 7.6g

(4)Analysis of causes of defects

The glue injection method is single-point injection. After the glue flow enters the mold cavity, it requires sufficient time to fill to saturation. Within a unit of time, if

If the pressure is too low, the product will cool and shrink unevenly. Uneven heating of the mold itself and insufficient temperature can also cause the product to cool and shrink unevenly

Consistent

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Use medium speed in the second section Just fill a very small area near the glue inlet. The third section is filled with 90% of the mold cavity at medium speed to cool the molten rubber material that is not yet warm Inconsistency creates light and shadow. In the fourth section, fill the mold cavity slowly to completely expel the air inside the cavity, avoiding trapped air and charring, etc Adverse phenomena. Finally, switch to the pressure-holding switching. position.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Injection molding process table

| Injection molding machine: Haitian 160T Type A screw injection capacity 250g | Product Name: Razor Housing |

| Raw material: ABS PA757 | Colour: Black | Drying temperature: 85°C | Drying method: Dehumidifying dryer | Drying time: 2.5 hours | Recycled material usage: 0 |

| Finished product weight: 27.1g×2=54.2g | Nozzle weight: 7.6g | Mold output: 1×2 | Gate injection method: Point gate | ||

| Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | Front and rear mold cavities | Constant temperature machine | 85°C | 80°C |

| 240°C | 235°C | 230°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | Lateral position | Constant temperature machine | 70°C | 68°C |

| △ | △ | △ | △ | △ | ||||

| / | 100/ | 120 | Holding pressure | Pressure-holding position | 100 | 100 | 110 | 125 |  Injection pressure Injection pressure |

| / | 1.3 | 1.5 | Holding pressure time | "End | / | 15 | 45 | 70 |  Injection velocity Injection velocity |

| Residual amount of injection glue | / | / | / | / | 12 | 25 | 35 | 45 |  Velocity of fire position Velocity of fire position |

| 7.8 | / | / | / | / | 5 | / | / | / |  Injection time Injection time |

| Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 26 | 60 | 5 | 10 15 10 | 10 | 70 | 3 |

| Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 140 | 50 | 1 | 15 35 38 | / | / |

Related News

Injection molds: The "Industrial Gene" Hidden Behind Everything

2025-07-12

Injection molds: The "Industrial Gene" Hidden Behind Everything When our fing...

Causes of defects in injection molded products

2025-07-27

Causes of defects in injection molded products The electrical part of the inj...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

The setting of injection molding temperature and time parameters

2025-07-27

The setting of injection molding temperature and time parameters1. Setting of te...

Injection mold: The "Invisible Creator" in the workshop

2025-07-09

Injection mold: The "Invisible Creator" in the workshopI. First Impression of th...

NowOn behalf of the manufacturing industry precision "molding magician"

2025-06-29

NowOn behalf of the manufacturing industry precision "molding magician" In today...