Classification of injection molds

Classification of injection molds

Different types of molds have different requirements for design drawings and mold steel. China has not yet classified injection molds. The following is the classification standard of SPI-SPE in the United States

(1) Class 101 modules

SPI-SPE standard, with a production life of 1 million times, long-life precision injection molds

1.Detailed mold assembly drawings and part drawings are required.

2.The minimum hardness of the mold base material is 280BHN (DME#2 steel /4140 steel).

3. For inner mold inserts with cavities, the steel must be hardened to 48 to 50HRC. Other parts such as sliders, wedge blocks, and pressure blocks should also be hardened. The main dimensional accuracy grade of the formed parts is taken as 1T5

4. The push rod plate should have guide pins.

5. The slider should have wear-resistant blocks.

6. If necessary, the fixed mold, moving mold and slider should be equipped with temperature control systems.

7. For all cooling water channels, it is recommended to use nickel-free electroplating or 420 stainless steel inserts. This can prevent rust and facilitate the cleaning of garbage.

8. A straight positioning block or a conical positioning block is required

(2) Type 102 mode

The production life is 500,000 to 1,000,000 times, and injection molds are produced in large quantities

1.Detailed mold assembly drawings and part drawings are required.

2.The minimum hardness of the mold base material is 280BHN (DME #2 steel /4140 steel).

3. For inner mold inserts with cavities, the steel should be hardened to 48 to 52HRC, and other important parts should also be treated uniformly. The main dimensional accuracy grade of the formed parts is taken as IT6.

4. It is recommended to use straight positioning blocks or conical positioning blocks

5. The following items may or may not be required, depending on the final production quantity. When quoting, if the following items are adopted, it is necessary to check clearly whether they are required

a. Push rod plate guide column;

b. Slider wear-resistant block;

C. Electroplating cooling water holes and electroplating cavities.

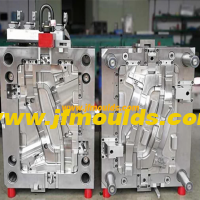

Automobile parts mold Manufacturer in China (jfmoulds.com)

(3) Class 103 mode

Medium batch injection molds with a lifespan of 100,000 to 500,000 times

1.Detailed mold assembly drawings are required.

2.The minimum hardness of the mold base material is 165BHN (DME#1 steel /1040 steel).

3. The steel for the inner mold inserts is P20 (28 to 32HRC) or high-hardness steel (36 to 38HRC). The main dimensional accuracy grade of the formed parts is taken as IT7

4. Other requirements will be determined based on specific needs.

(4) Type 104 module

Injection molds with a production life of 5 to 100,000 times and for small-batch production

1. A mold structure diagram is required.

2. The formwork base material is P20 (28 to 32HRC), and soft steel (steel below 40HRC) or aluminum can also be used.

3. The inner mold components can be made of aluminum, soft steel or other common metals, and the main dimensional accuracy grades can be 1T7 to 1T8.

4. Other requirements will be determined as needed.

(5) Type 105 mode

The production life is less than 500 times, single-piece production, for making prototypes or test molds.

Aluminum alloy, epoxy resin or any other material can be used. As long as it has sufficient strength, the minimum test quantity can be produced.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Solutions to problems such as poor transparency, unstable dimensions, spots, and black lines in injection molded products

2025-07-31

Solutions to problems such as poor transparency, unstable dimensions, spots, and...

The U-shaped position of the mold is filled with water lines and trapped air, which turns white

2025-08-06

The U-shaped position of the mold is filled with water lines and trapped air, wh...

The structure, materials and design of injection molds

2025-07-18

The structure, materials and design of injection molds In the vast landscape ...

The glue inlet position of the mold is dragged and charred

2025-08-06

The glue inlet position of the mold is dragged and charredThe glue inlet of the ...

Injection mold commonly used six kinds of mold materials

2025-06-19

The choice of steel not only affects the service life of the mold, but also affe...

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakthroughs

2025-07-15

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakt...