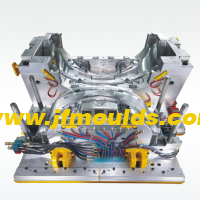

The drawing of the mold and the inking of the gate

The drawing of the mold and the inking of the gate

Mold drawing

Phenomenon: The two products are textured products and there is a phenomenon of mold pulling.

Analysis: Slow speed will cause the product to cool down too quickly. The position switching is too slow.

Characteristics of injection molding machines

Grade: DEMAG(Ningbo), clamping force: 120t, plasticizing capacity: 130g.

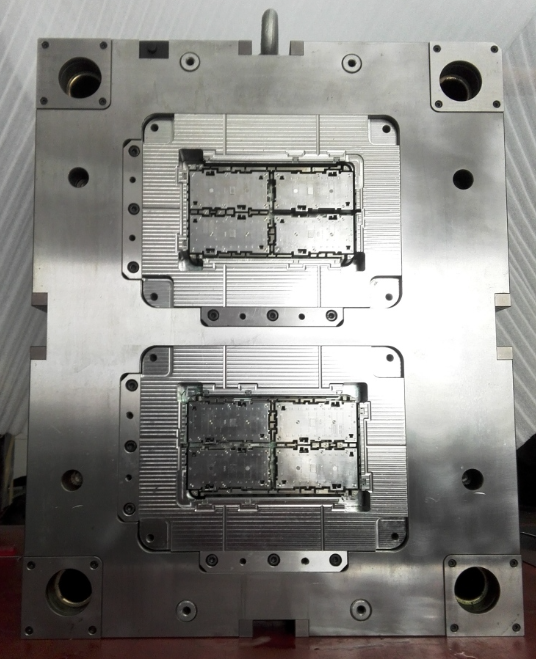

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: push plate ejection, mold temperature: 90°C (constant temperature machine).

(3) Product physical evidence

Material: PC+ABC HP5004-100, Color: black, Product weight (single piece) : 3.2g, nozzle weight: 13g.

(4) Analysis of causes of defects

1.The main channel of the mold is long and thin. The glue inlet method is submersible glue inlet. The molten material flows near the glue inlet. Due to the slow speed, the local pressure of the product is too large, resulting in the mold pulling phenomenon.

2. The inherent limitations of the equipment itself have led to the inability to improve the situation through machine adjustment.

(5) Countermeasures

The products debugged after replacing the DEMAG 100T machine are qualified, and the injection speed of the machine can reach 220mm/s.

Injection molding process table

Injection molding machine: Haitian 1201T, Type B screw, injection volume 131g | Product Name: M169 Battery Frame | ||||

Raw materials: ABS+PC HP5004 | Colour: Black | Drying temperature: 100°C | Drying method: Dehumidifying dryer | Drying time: 4 hours | Recycled material usage: 0 |

| Finished product weight: 3.2g×2=6.4g | Nozzle weight: 13g | Mold output: 1×2 | Gate injection method: Point gate | ||

| Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 110°C | 102°C |

| 320°C | 315°C | 315°C | 300°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 110°C | 101°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |

| ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Mold ink flushing

Phenomenon: Ink surges at the gate of the S10 face frame.

Reason: During IML injection molding, the gate of the sheet material often appears transparent.

Analysis: High speed will cause material melting, intensify shearing and generate high temperatures. The ink has poor heat resistance.

Characteristics of injection molding machines

Grade: DEMAG (Ningbo), clamping force: 50T, plasticizing capacity: 42g.

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: push plate ejection, mold temperature: 70°C (constant temperature machine).

(3) Product characteristics

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 1.5g, sprue weight: 13g.

(4) Analysis of causes of defects

1.The main channel of the mold is quite large, and the glue inlet method is submersible glue inlet. When the molten material flows near the glue inlet, due to the excessive speed, it causes high shear, resulting in a rapid and instant temperature rise of the molten material.

2. The ink is not resistant to high temperatures, resulting in ink flushing.

(5) Countermeasures

1.Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. In the third section, quickly fill 90% of the mold cavity to prevent the high-temperature molten rubber from cooling. In the fourth section, slowly fill the mold cavity. Finally, switch to the pressure-holding switching position.

Injection molding process table

Injection molding machine: DEMAG50T, Type B screw, injection capacity 42g | Product Name: Transparent Mirror | ||||

Raw material: ABS PA758 | Color: Transparent | Drying temperature: 70°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

| Finished product weight: 1.5g×8=12g | Nozzle weight: 13g | Mold output: 1×8 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 72°C |

| 260°C | 255°C | 250°C | 210°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 71°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |  Injection pressure Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Diversification of injection mold enterprises

2025-06-28

Diversification of injection mold enterprises1. Automotive Molds: Driving Indust...

Define a new paradigm for the injection mold industry through technological breakthroughs and ecological reconstruction

2025-07-04

Define a new paradigm for the injection mold industry through technological brea...

Surface treatment of molds

2025-07-26

Surface treatment of molds1. Common surface treatment processes The purpose o...

Multi-component mold

2025-07-25

Multi-component moldIn multi-component injection molding (also known as multi-co...

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

Solutions to problems such as poor transparency, unstable dimensions, spots, and black lines in injection molded products

2025-07-31

Solutions to problems such as poor transparency, unstable dimensions, spots, and...

Injection pressure

Injection pressure