Standard parts of molds

Standard parts of molds

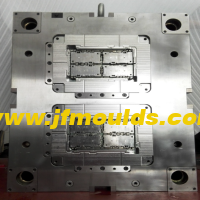

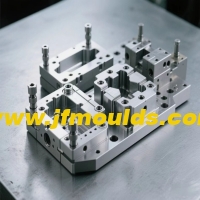

1 Mold frame

Prefabricated standard mold base assemblies or components provide great convenience for mold manufacturers. A standard mold base consists of a lower half mold and an upper half mold equipped with guide pins.

In the early days, the template combination only included the guide pins of the ejector plate and the side guide pins of the fixed mold. Nowadays, complete mold bases can be purchased.

Mold manufacturers can now focus on the manufacturing of mold components, such as cavities. Standard parts have greatly reduced the depth processing range and processing time in mold manufacturing.

Nowadays, standard formwork frames of different sizes are available for purchase, with dimensions up to 796mmX996mm, and the thickness of the formwork varies from 10 to 196mm. The quality of steel can also be selected.

All surfaces of each template are ground, with surface parallelism reaching 0.008/100mm and thickness tolerance ranging from +0.05 to 0.25mm. With such a configuration, mold manufacturers do not need to reprocess the templates. Templates of various sizes are all equipped with the required guiding components, such as guide posts, guide sleeves and sleeves.

A wide range of hot runner and nozzle series, including melt and temperature control circuits, have enriched the variety of standard parts.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

2. Mold guiding components

To prevent the inserts and cores inside the mold from being damaged during mold closing, mold guiding components need to be used. For small and lightweight molds, guide pins and guide sleeves are usually used.

All the guiding components of the mold need to be hardened. Once they are worn, they can be replaced. To prevent plastic parts from being contaminated by grease, the guiding components usually operate without lubricating oil. Standard parts manufacturers can provide self-lubricating and maintenance-free guide sleeves, thus eliminating the need for oil or grease. The guiding components can be used under conditions where the mold temperature can reach up to 200° C.

Depending on different usage requirements, circular or square center positioning units can be used. The special center positioning component can eliminate the unbalanced force on the guiding component during mold closing and achieve a high-precision tight fit.

For medium and large-sized molds, it is recommended to provide support for the molds through injection molding machines. With support blocks, the mold can be supported by the injection molding machine's green column or slide along the guide rail of the machine template.

3 Demolding components

The demolding components include ejector pins, telescopic cores, sliders, clamping blocks and various forms of edge locks.

The ejector pin should be selected with a larger diameter and capable of providing sufficient demolding force for the product. The thrust of the ejector pin must be greater than the adhesion between the product and the cavity. If the adhesion is too large, deformation or damage of the injection molded part often occurs during demolding. The position where the ejector pins are arranged should avoid the demolding force acting only on the circumference of the injection molded part.

Telescopic core

For demolding parts with internal upturns or internal threads, telescopic cores should be used. These cores have been hardened, and except for the threaded parts which need to be processed, the other parts can be installed at any time.

Slider, hold the assembly block tightly

External inverted demolding usually relies on laterally moving components, including sliders, clamping blocks and cylinder core-pulling.

In molds with multiple parting surfaces, edge locks are needed to open the secondary parting surfaces.

4 Mold cooling accessories

To achieve effective mold cooling, some relevant standard accessories can be used. Such as quick water, oil pipe joints, heat-conducting cores, diversion elements and threaded cores.

Quick connector

Standard parts manufacturers can provide a complete range of water/oil quick couplings. The most commonly used diameters are 9mm, 13mm and 19mm. The diameter of the fine and small core can even reach 5mm.

Quick couplings can be equipped with control valves or not. The characteristic of a valveless system is that the pressure drop in the cooling water channel is very small, while in a valveless system, the cooling medium will not be lost when the joint is loosened, and it can prevent corrosion caused by oxygen infiltration.

Threaded core

The threaded core is precisely fitted into the inner hole of the core, allowing the cooling medium to flow smoothly along the inner wall and ensuring good heat transfer. There are two types of threaded cores: single-ended and double-ended. In a single-ended threaded core, the cooling medium is introduced through a hole in the core and then flows back along the threaded ring. And the double-ended threaded core is composed of.

The cooling medium is introduced through the first helical channel and discharged through the second helical channel.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

5. Quick mold changing system

The quick mold changing system not only enables rapid clamping of molds but also enables quick connection of all necessary equipment.

When changing molds, the time required for mold clamping is actually very short. The most time-consuming parts are the coupling of the machine's ejection mechanism, the connection of the cooling water circuit, the connection of the limit switch and the mold heating system, as well as the connection between the hydraulic core-pulling and the machine. And all these elements are indispensable parts of an excellent mold changing system.

Only 0.5% of injection molding companies can find fully automatic solutions. The cost of semi-automated mold changing is also relatively low. Many semi-automated components are provided by standard parts suppliers.

The steps of semi-automated mold changing include:

(1) Use mechanical, hydraulic clamping components or magnetic locking templates.

(2) Quick couplings using cooling water and hydraulic oil.

(3) Quick couplings for the ejection system.

(4) System plug-in device for hot runner and limit switch.

The following practices have been proven effective:

(1) The connection of the cooling medium is accomplished by the water collection block fixed on the machine template.

(2) The connection points of the cooling water pipes should be marked with colors for inflow and outflow.

(3) The junction box should be installed on the mold to avoid incorrect connection.

6-side lock mechanism

The edge lock mechanism realizes the mechanical movement of the template during the mold opening action.

Providing additional travel for the template or fixing the position for removing the template is a task that the edge lock mechanism needs to complete. When opening the mold, the side lock can open an additional parting surface. During the mold opening movement, the side lock pulls the demolding back through the mechanical inclined wedge until the demolding stops moving, while the mold will continue to move. The side lock does not require any electrical components for control and is locked entirely by mechanical structure. Edge locks are very commonly used, and standard parts suppliers can provide various types of products.

Heating plates for thermosetting plastics and elastomers

In the processing of thermosetting plastics or elastomers, injection molding machines are often equipped with heating plates. The advantage is that the mold temperature can be raised without installing heating components on each set of molds.

The heating plate is usually installed on the fixed template or ejection plate of the injection molding machine, and it is equipped with heating elements and sensors for temperature control. Heating plates equipped with heating sleeves or heating coils can be set to different temperatures to meet the heating requirements of various molds.

The thermal output power of the heating plate is 5000 to 7000 watts. But they are not omnipotent and are only suitable for simple and flat products. For products with a large height difference, due to the excessive temperature difference inside the mold, the heating plate is not very suitable. In this case, it is best for the mold to be equipped with an independent heating device.

If the positions of the heating elements and temperature sensors are arranged reasonably, the temperature on the mold surface can be effectively controlled. The temperature difference on all surfaces of the mold should be within ± 5℃. In this way, the hardness of the injection molded parts is uniform, and at the same time, the occurrence of internal stress and warpage can be prevented.

8. Demolding brush for elastomers

Most elastomer products are soft but unstable. They cannot be ejected with normal ejection components. These products must be removed by hand with a brush or by a mechanical hand system.

The brush removal unit drives the rotating brush to brush over the mold surface, and the product is brushed out of the cavity as the brush rolls in the reverse direction. This kind of institution is a variant of the pushout institution. With this brush, the flash, injection system and runner of the product are simultaneously brushed out of the mold cavity. Brushes are also frequently used to ensure that there is no product or runner residue.

Residue remains on the ejection side or injection molding side.

Brushes are usually made of natural bristles such as fur or rubber strips and need to withstand a temperature of 250℃. Not all materials are suitable.

The diameter of the brush can be changed by replacing the brush head. This brushing unit can also be adjusted to perform strong brushing or gentle brushing.

To ensure 100% cleanliness of the mold, an image monitoring system can be used. This system can detect whether the gate or product is stuck, thereby initiating the second or third cleaning.

Related News

The drawing of the mold and the inking of the gate

2025-08-05

The drawing of the mold and the inking of the gateMold drawing Phenomenon: Th...

Types and basic requirements of mold design drawings

2025-09-07

Types and basic requirements of mold design drawingsTo shorten the production cy...

Multiple mold designs

2025-07-25

Multiple mold designsIn-mold labeling processThin-walled plastic packaging produ...

Focus on quality and deeply cultivate innovation

2025-07-05

Focus on quality and deeply cultivate innovation In daily life, from the mobi...

Solutions for delamination, peeling, hardening and fragility of injection-molded products

2025-08-01

Solutions for delamination, peeling, hardening and fragility of injection-molded...

The surface baking printing and light and shadow of the mold

2025-08-04

The surface baking printing and light and shadow of the moldSurface baking and p...