How to solve the problems of surface dents and mold on injection molds

How to solve the problems of surface dents and mold on injection molds

Concave points on the surface of the injection mold

Phenomenon: Concave spots on the surface of the face frame

Reason: During the in-mold injection molding of IML sheet materials, many concave points appear on the product surface.

Analysis: There is a bit of dust on the surface of the PC sheet. The air cleanliness in the environment is not high, and there is a lot of dust, which causes depressions to occur when the sheet is placed in the mold for injection molding.

(1)Characteristics of injection molding machines

Grade: DEMAG, clamping force: 50t, plasticizing capacity: 42g.

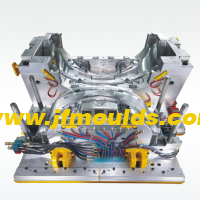

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 70°C (constant temperature machine)

(3) Product physical evidence

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 2.4g, sprue weight: 8.44g.

(4)Analysis of causes of defects

1.There is a bit of dust on the surface of the PC sheet. When it is placed in the mold for injection molding, the dust spots are injected onto the surface of the product.

2. The air environment is clean with a lot of dust. When the mold is opened, the dust adheres to the surface of the front mold core and causes concave points when the next mold is recycled.

(5)Countermeasures

1. Manually wipe the surface of the sheet material to minimize the dust points.

2. Purify the purity of the air and regularly clean the machine and its surrounding environment.

Injection molding process table

Injection molding machine: DEMAG50T, Type B screw, injection capacity 42g | Product Name :S10 Face Frame | ||||

Raw material: ABS PA785 | Color: Transparent | Drying temperature: 80°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 2.4g×2=4.8g | Nozzle weight: 8.44g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 62°C |

| 260°C | 255°C | 250°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 59°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | 10 | / | 55 | 3 | Injection velocity | ||||

| 7.8 | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

The injection mold is moldy

Reason: This is an IML injection molded product. Due to the temperature difference on the mold surface when the sheet is installed, it forms a semi-transparent state.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. The surface temperature of the mold is too low. The temperature of the material pipe is too low.

(1)Characteristics of injection molding machines

Grade: DEMAG (Ningbo), clamping force: 50t, plasticizing capacity: 42g.

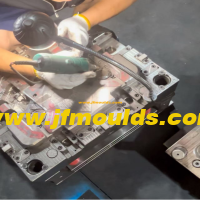

(2) Mold characteristics

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 60°C (constant temperature machine)

(3) Product physical evidence

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 2.43g, sprue weight 8.44g.

(4)Analysis of causes of defects

The mold temperature is low, and the inlet method is potential inlet. The molten material flows to the vicinity of the inlet. Due to the excessive speed and the very smooth surface of the mold, high shear occurs, causing the molten material to heat up rapidly in an instant, until the surface turns white and forms a semi-transparent state.

(5) Countermeasures

1. Utilize multi-level injection and position switching.

2. Appropriately increase the mold temperature to allow the product to cool down slowly in the mold.

3. Appropriately increase the temperature of the melt cylinder to enhance the transparency of the product.

Injection molding process table

| Injection molding machine: Demag 50T, Type B screw, injection capacity 42g | Product Name: S10 Face Frame | ||||

| Raw material: ABS PA758 | Color: Transparent | Drying temperature: 80°C | Drying method: Dehumidifying dryer | Drying time: 2 hours | Recycled material usage: 0 |

Finished product weight: 2.43g×2=4.86g | Nozzle weight: 8.44g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 80°C | 73°C |

| 242°C | 236°C | 227°C | 200°C | / | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 80°C | 67°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 | Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

Surface treatment of molds

2025-07-26

Surface treatment of molds1. Common surface treatment processes The purpose o...

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

A Comprehensive Guide to Injection Molds: From Basics to Applications

2025-07-11

A Comprehensive Guide to Injection Molds: From Basics to Applications In the vas...

The key to plastic product molding

2025-07-21

The key to plastic product moldingBehind today's dazzling world of plastic produ...

Focus on quality and deeply cultivate innovation

2025-07-05

Focus on quality and deeply cultivate innovation In daily life, from the mobi...

Injection molds: The "Industrial Gene" Hidden Behind Everything

2025-07-12

Injection molds: The "Industrial Gene" Hidden Behind Everything When our fing...