Dimension marking of the mold design drawing

Dimension marking of the mold design drawing

I. General Requirements for Dimension Marking in Mold Design Drawings

1. The units used for marking dimensions: The dimension units in the mold drawing include metric and imperial systems. Among them, countries such as the United Kingdom, the United States, Canada, India, and Australia use the imperial system, while China uses the metric system. However, if the customer is from any of the above countries, it is advisable to use the imperial system. In addition, many standard parts in the mold (such as screws, push rods, etc.) are in imperial units. Therefore, even if other dimensions are in metric systems during mold design, the dimensions of these standard parts are still marked in imperial units.

2. The precision adopted when marking dimensions.

Linear dimensions: Metric system uses two decimal places X.XXmm, and imperial system uses four decimal places X.XXXXin.

Angle: Use one decimal place: X.X°.

3. Dimensional reference in the mold drawing

a. Product (plastic part) reference: The reference based on the customer's product drawings. All dimensions of the cavity and core shall be based on the plastic part reference as the design reference.

The dimensions of the core and cavity in the mold design drawing should correspond one-to-one with those in the product drawing.

b. Mold assembly reference: Generally, the center of the mold base is taken as the assembly reference. All dimensions related to the assembly of the mold base, such as screw holes and cooling water holes, should be based on the assembly reference as the design reference.

c. Process reference: The reference determined based on the processing and measurement requirements of the mold parts, such as the counterbore of the insert hole should be based on the bottom surface

The selection method of the dimensional reference for the mold drawing is as follows

a. In the sectional view, the parting surface is taken as the reference, and reference symbols are added simultaneously. Sometimes, product engineers may require a reference based on the plastic part drawing. In such cases, the plastic part reference coincides with that in the mold drawing

b. In the floor plan, the situation is rather complex and should be treated differently.

If the plastic part is symmetrical, use two center lines as references and add reference symbols at the same time.

If only one axis is symmetrical while the other is asymmetrical, and if there is a column position, the center of the column should be taken as the reference. If there is no column position, take the longer straight line or straight edge as the reference.

If both axes are asymmetrical, select the column position or the straight side as the reference.

The correct selection of dimensional references is an important condition for ensuring the design requirements of parts and facilitating processing and measurement.

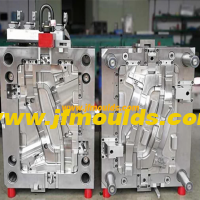

Fan mold Manufacturer in China (jfmoulds.com)

4. The dimensioning of the same structure should be uniform in different attempts. For example, uniformly mark according to the large end size. If necessary, the demolding Angle should also be marked, such as 50±3°. For the dimensions of the reinforcing ribs (RIB) and holes, only the center size, width, depth and diameter need to be marked. The demolding Angle should be marked separately.

5. The position and size of the push rod holes only need to be marked on the inner mold insert drawing. They do not need to be marked on the push rod fixing plate or the template drawing, but the diameter of the push rod holes should be specified.

6. For CNC machined parts, it is not necessary to mark all dimensions. Only the important reference data and inspection data need to be marked.

7. The main dimensions marked on the moving and fixed inserts are: wire cutting; Screws, cooling water holes, push rod holes; Height difference of the parting surface; The matching dimensions of the shape, etc. For clarity, the above can be marked on one or more drawings.

8. For wire-cut dimensions, only the main dimensions should be marked. For complex contours, the wire-cut part can be copied out and drawn separately, and noted on the original drawing.

9. Non-standard formwork bases need to be marked with the positions and dimensions of the template type screw holes, reset rods, guide pins, etc., as well as the NC detection dimensions of the moving and fixed formwork frames. However, standard formwork bases do not need to be marked (and guide pins, reset rods, and push rod plate guide pins are no longer ordered in standard parts).

When marking the processing position of the reinforcing rib electrode, it is only necessary to mark the center position of the electrode.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Ii. Requirements for Dimension Marking of Assembly Drawings

1. The ranking map adopts the coordinate annotation method, with the center of the mold as the coordinate origin. The sectional view adopts linear dimensioning.

2. The assembly drawing mainly marks the following dimensions.

a. Dimensions of the connection parts of the injection molding machine;

b. The dimensions of all parts that are not separately drawn in the part drawing (mainly the processing part of the mold frame), but the positions of the standard holes on the mold frame may not be marked

c. Position and size of each cavity, and try to take the nearest whole number;

d. The position of the gate and the gate sleeve screws;

e. The size of the template and the size and position of the inner mold inserts;

f. The position and size of the lateral core-pulling mechanism and its accessories;

8. The position and size of the positioning block;

h. Location, specification and number of cooling water holes;

The diameter and position of holes i.K.O;

J. The length and size of the guide pins and guide sleeves of the push rod plate;

k. Position and diameter of the support columns (S.P);

1. The diameter and length of the reset spring, the depth and diameter of the spring hole, and the spring specification should be marked;

m. The diameter and thickness of the limit nail;

n. The position and length of the spacing parting mechanism in the three-plate mold and the two-plate half-mold.

Three: Requirements for dimension marking of parts

1. Correct: Dimensional marking should comply with the basic provisions of the national standard "Mechanical Drawing"

2. Completeness: Dimensional annotations must ensure that all production activities in the factory can proceed smoothly and facilitate reference and search based on the drawings.

3. Clarity: The size configuration should be uniform and standardized

4. Reasonable: The dimensional marking should comply with the design and process requirements to ensure the performance of the mold.

5. For parts with a slope, the "large" and "small" should be noted beside the dimension marking to indicate the dimensions of the large and small ends.

6. Basic Requirements: The maximum external dimensions must be directly marked on the drawing. If a closed dimension chain is generated, parentheses can be added to the maximum external dimension.

7. Dimensions should be marked outside the view as much as possible to avoid the intersection of dimension lines, dimension numbers and the contour lines of the view.

8. The diameter dimensions of concentric cylinders are best marked on non-circular views

9. Parallel dimensions should be arranged in order of size, with smaller dimensions inside and larger dimensions outside, and their dimensions should be adjusted accordingly

10. The dimension lines should be neatly arranged, and they should be placed on the same side as much as possible. It is best to arrange the relevant dimensions in a straight line. The size numbers are staggered. In densely populated areas, the markings should be enlarged to avoid misunderstandings.

11. Important positioning dimensions in the cavity, such as holes, ribs, and grooves, should be directly marked on the reference.

12. All structures must have positioning and shaping dimensions. For the positioning dimensions of holes, ribs and grooves, the center line should be taken as the standard.

13. When marking the dimensions of sectional views, to ensure clarity, clarity and neatness, the inner and outer dimensions should be marked on both sides respectively.

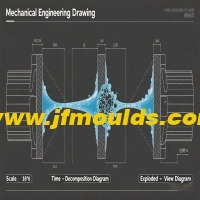

Four: Examples of Dimension Marking on Mold Design Drawings

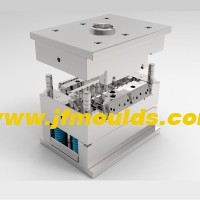

(1) Examples of dimension marking on mold assembly drawings: Due to the large number of dimensions to be marked on the assembly drawing, for the sake of clarity, in the actual working process, the main section views in the assembly drawing are not marked with section lines.

(2) An example of dimension marking for the B board of the moving mold

The structure of the moving die B plate includes: die frame, cooling water circuit, screw holes, push rod (push tube) holes, reset rod holes, holes of the spacing and parting mechanism, and sometimes a lateral core-pulling mechanism, etc. An example of dimension marking is shown in Figure 1-27. The X and Y directions are marked by the coordinate method, with the center line of the mold as the reference. The height dimensions are marked using the linear marking method, with the bottom surface of the template as the reference. Different push rod through holes are represented by different symbols, and their sizes and quantities are listed together

(3) Examples of dimension marking for fixed mold A plates

The marking method for Board A is the same as that for board B

(4) Examples of internal mold insert dimension marking: Generally, insert diagrams are divided into insert screw hole diagrams, cooling water channel diagrams, and insert processing diagrams. The

shape of the insert is simple. The screw holes, cooling water circuit diagram and processing drawing are reflected on the same drawing. Precautions when marking the insert:

1. The direction and reference Angle should be accurately marked on the die side.

2. Express the drawing completely with the fewest views, and mark the dimensions of a shape as clearly as possible on one view.

3. The surfaces that are bumped through and rubbed through should be marked with words.

4. The parting surfaces should be marked according to the positions on the assembly drawing. The reference angles should be specified and the references should be consistent with those on the assembly drawing.

5. For quenched inserts, the draft Angle of the inner mold insert forming surface should be indicated. If the draft Angle of the cavity is 1.5°, the marked size should be the large head (end) size.

Related News

Surface treatment of molds

2025-07-26

Surface treatment of molds1. Common surface treatment processes The purpose o...

Methods for the easy breakage of the internal position of the mold and the easy damage of the screw column during the mold opening process

2025-08-07

Methods for the easy breakage of the internal position of the mold and the easy ...

The methods for adjusting parameters for defects in injection molded products are as follows

2025-08-01

The methods for adjusting parameters for defects in injection molded products ar...

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakthroughs

2025-07-15

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakt...

Performance characteristics and selection criteria of injection molds

2025-06-30

Performance characteristics and selection criteria of injection molds This ...

The U-shaped position of the mold is filled with water lines and trapped air, which turns white

2025-08-06

The U-shaped position of the mold is filled with water lines and trapped air, wh...