From custom development to global supply, unlock the core driving force of modern manufacturing

From custom development to global supply, unlock the core driving force of modern manufacturing

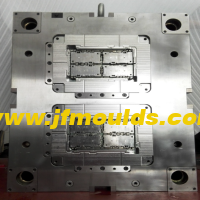

In plastic processing and modern manufacturing, injection molds serve as the "bridge" connecting design concepts with mass production. From daily necessities to precision industrial components, the birth of almost all plastic products is inseparable from the support of high-quality molds. Nowadays, as the market's demands for product personalization, precision and efficiency continue to rise, the injection mold industry is rapidly developing in the direction of customization, high precision and globalization. This article will comprehensively analyze the core value and selection logic of injection molds from custom development, industry application, technical advantages to global supply.

Customization and prototype development: The first step from requirements to implementation

"There are no standardized molds, only standardized qualities" - this is one of the core logics of the injection mold industry. Custom molds (molds) and Prototype molds (molds) are key to meeting diverse demands. Whether it is the small-scale trial production of start-ups or the iteration of innovative products of large enterprises, customized services can precisely match the product size, material properties (such as PP, ABS, PE, etc.) and production process requirements.

Prototype molds are particularly important. Before the official mass production, samples can be made through prototype molds to quickly verify the rationality of the design and test the performance of the product, avoiding cost waste after large-scale production. For instance, for a newly designed electronic housing, 10 to 50 samples can be produced through prototype molds. This enables the detection of structural defects during assembly tests, thereby optimizing the mold design and ultimately enhancing mass production efficiency.

Trash can mold Manufacturer in China (jfmoulds.com)

Cross-industry application: How Molds Can Adapt to the "Special Requirements" of Different Fields

The application of injection molds has long permeated every corner of the manufacturing industry. Different industries have significant differences in the performance requirements for molds, which has also promoted the specialized division of labor in mold manufacturing:

- Automotive industry: Automotive plastic parts (such as instrument panels, bumpers, connectors) have extremely High precision requirements for molds. Errors at the millimeter or even micrometer level may affect assembly accuracy or service life. High-quality automotive molds need to withstand high-intensity production (with up to thousands of injection molding cycles per day) while ensuring stability.

In the medical industry, medical devices (such as syringes and test kit shells) come into direct contact with the human body or samples. The molds must meet medical-grade clean standards. Surface smoothness and material compatibility (such as chemical corrosion resistance) are core indicators to avoid product contamination risks.

In the Electronics industry, consumer electronics (such as mobile phone casings and connectors) tend to be miniaturized and integrated. Correspondingly, electronic mold manufacturers need to achieve precise forming of fine structures (such as 0.1mm card slots), while meeting the production requirements of high injection rate and low loss.

- Packaging industry: Food and daily necessities packaging have strict requirements for production efficiency. Packaging mold suppliers need to support high-speed injection molding (up to dozens of cycles per minute), while ensuring sealing performance (such as leak-proof design of bottle cap molds), taking into account cost and quality.

Technology and Service: A dual guarantee of efficiency and quality

In the fierce market competition, the technical strength and supporting services of molds have become the core considerations for enterprises when choosing suppliers

- High-precision manufacturing: Relying on advanced equipment such as CNC machining centers and EDM electrical discharge forming, high-precision molds (High precision molds) can control dimensional tolerances within ±0.005mm, ensuring product consistency - which is crucial for precision components such as automotive seals and medical catheters.

- Rapid response capability: Market demands change rapidly. Fast mold production can shorten the traditional mold delivery cycle of 45-60 days to 20-30 days, helping enterprises seize the opportunity to go public first. It is particularly suitable for seasonal products (such as festival packaging) or urgent orders.

- Full-process OEM support: Professional OEM mold solutions cover the entire chain of services from product design optimization (DFM analysis), mold manufacturing, trial mold adjustment to mass production. Suppliers are not only "mold producers", but also "production partners", helping customers avoid process risks and reduce overall costs.

Global Supply and Cooperation: How to Choose a Reliable Mold Partner?

With the deepening of the global layout of manufacturing, It has become a trend to choose Global mold manufacturers or regional suppliers (such as USA mold suppliers, Germany injection molds). High-quality global suppliers have three major advantages:

1. Localization adaptation: Familiar with regional market standards (such as the US FDA, EU CE), mold design complies with local material environmental protection requirements (such as RoHS, REACH), reducing cross-border compliance risks;

2. Efficient communication: By providing technical support and after-sales response through the localization team, communication costs caused by time differences and cultural differences are avoided.

3. Flexible cooperation mode: Support B2B mold suppliers, online inquiry and order tracking, adapt to the trend of digital procurement, and make cross-border cooperation more efficient.

The mold is the "cause" and the product is the "effect"

The quality of injection molds directly determines the precision, consistency and production cost of plastic products. Whether it is the pursuit of customized small-batch development or the need for high-precision industry-level applications, choosing a mold supplier with technical strength, rapid response capabilities and a global service network is the key for manufacturing enterprises to reduce costs, increase efficiency and enhance competitiveness.

If you are seeking a reliable mold solution for product launch - from prototype verification to mass production, from local demand to global supply - you might as well start by clarifying the product characteristics (materials, precision, production capacity), and deeply collaborate with professional suppliers to make high-quality molds the "invisible cornerstone" of your product's success.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

Related News

From custom development to global supply, unlock the core driving force of modern manufacturing

2025-07-19

From custom development to global supply, unlock the core driving force of moder...

Methods for the easy breakage of the internal position of the mold and the easy damage of the screw column during the mold opening process

2025-08-07

Methods for the easy breakage of the internal position of the mold and the easy ...

The setting of injection molding pressure and flow parameters

2025-07-26

The setting of injection molding pressure and flow parameters1.Setting of inject...

Define a new paradigm for the injection mold industry through technological breakthroughs and ecological reconstruction

2025-07-04

Define a new paradigm for the injection mold industry through technological brea...

The drawing of the mold and the inking of the gate

2025-08-05

The drawing of the mold and the inking of the gateMold drawing Phenomenon: Th...

Injection mold: The "Invisible Creator" in the workshop

2025-07-09

Injection mold: The "Invisible Creator" in the workshopI. First Impression of th...