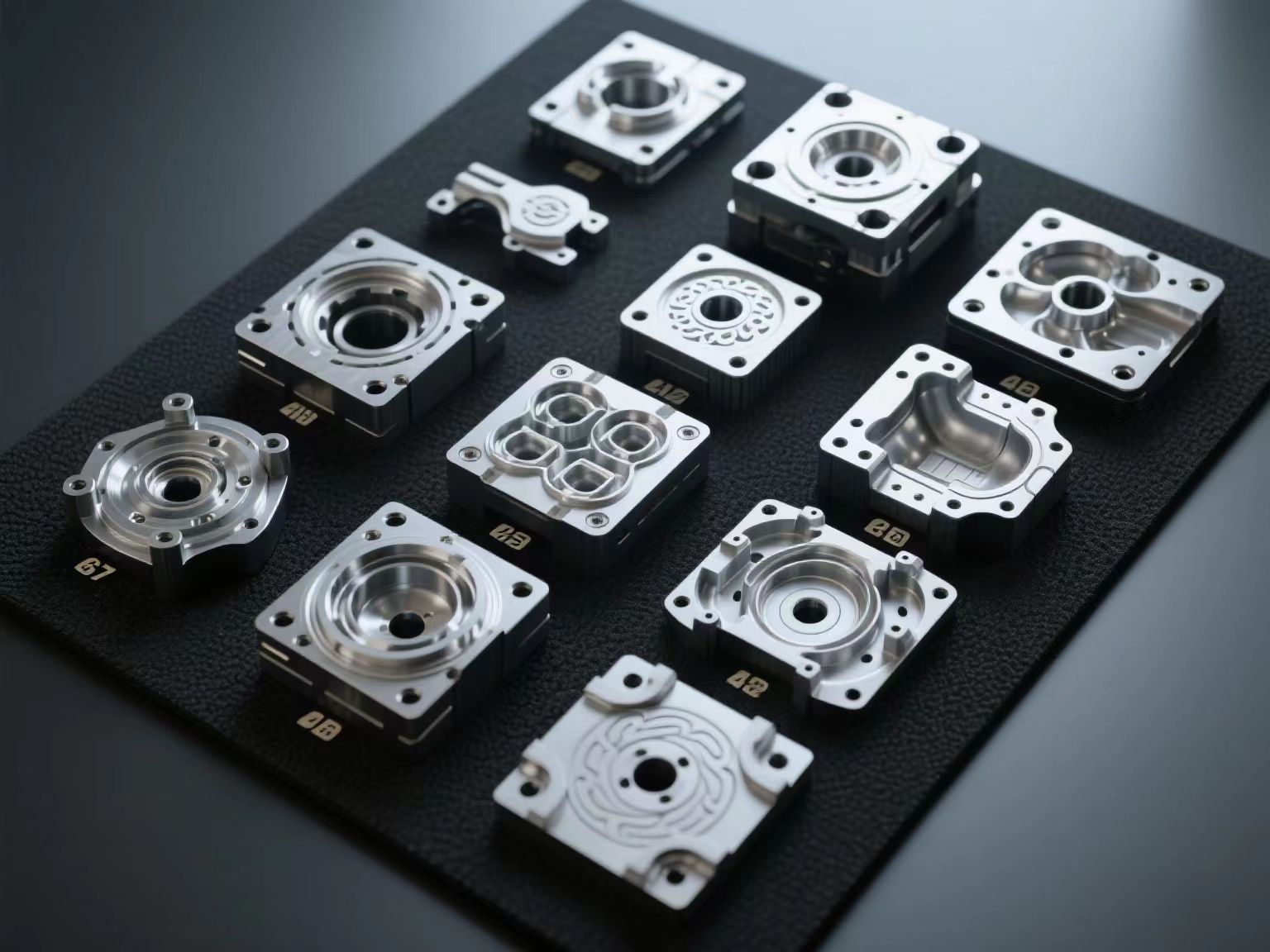

Multi-component mold

Multi-component mold

In multi-component injection molding (also known as multi-color injection molding - Translator's note) production, different plastics or plastics of different colors are used to produce injection molded products through different processes.

In recent years, with the continuous expansion of application fields, multi-component injection molding technology has become increasingly important. The ever-changing innovative solutions make multi-component injection molding increasingly attractive in the growing market.

One of the main reasons for the rapid growth of multi-component technology is the potential benefits brought by reducing production steps. By applying advanced mold technology, both manual and automated assembly processes of products can be completed within the molds. From the perspective of product design, multi-component injection molding technology is attractive in preventing design piracy and endowing sub-products with better tactile effects.

1.Slider technology (core retraction technology)

The greatest advantage of this process lies in the flexible selection of the position of the second component's inlet. Only when the slider in the cavity of the pre-plasticized part (I .e., the first component plastic - translator's note) is withdrawn can the second component plastic enter the space freed up in the pre-plasticized part.

By using the core retraction technology, closely connected products can be produced with compatible material combinations. That is, before the first component cures, the second component material is injected, and the mold does not need to be moved or opened.

Due to the rapid connection during the injection molding process, the connection between the two components in the product is very uniform, while the true tight interlocking of the geometric shape is achieved by the second component. In the molten state, the second component of the plastic can easily seep into the gaps of the first component. This technology is both simple and space-saving.

Because parallel injection molding cannot be achieved in the core retraction process, the injection molding times of the two materials are superimposed. Sequential injection molding of different components increases the total molding cycle. Due to this drawback, the core rollback method has been used less and less.

2. Transfer injection Molding process (mechanical hand transfer)

Transfer injection molding is used when injection molded parts need to be overmolded. The positions for pre-injection molding and final injection molding can be arranged left and right or up and down. The mechanical hand transfers the pre-plastic parts and grabs the finished products.

Similar to the core retraction process, this type of mold does not require rotational action, so its structure is not complicated. Its advantage is that the two materials can be injection molded simultaneously. Compared with the core retraction method, it will greatly shorten the molding cycle.

The transfer injection molding process also includes: pre-injection molding a certain product on one machine, then removing this pre-molded part and completing the injection molding with another material on another machine.

The process reliability of embedding preplastic parts into another cavity is extremely crucial. The process of adjusting the mechanical hand based on experience is rather complicated. A precise and controllable mechanical hand device is needed to ensure the accurate positioning of the pre-plastic parts at the final station.

The transfer injection molding process makes full use of the area of the existing mold panel, but it is not suitable for producing injection molded parts with very fine geometries.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

3.division plate mold

The dividing plate is integrated on the moving template and can rotate. After the mold is opened, the dividing plate transfers the pre-molded part to the next station of the mold, and the final product is injection molded.

A third rotatable template was added to the two templates of the dividing plate mold. This plate can rotate around the central axis. The dividing plate is first ejected and released from the moving die side, and then rotates around the central axis to the second position. The rotational motion driven by the rack is driven by a hydraulic motor or a servo motor, and its precision can reach tens of microns.

After the dividing plate rises, rotates and falls back, the core will return to its original position in the moving die. Then, the mold closes and the next injection molding cycle begins. At the second station, the pre-plastic part is embedded with another component of plastic.

The rotation of the dividing plate can be 2×180° or 3 × 120°. The third station is often used to cool or remove injection molded parts. Hot runners are used very limited in dividing plate molds.

4. Central support mold

The central stent system is similar to the indexing plate technology. The dividing plate can be simplified into a long strip plate or a cross shape. The central support only rotates the injection molded part to the next station without rotating any mechanical components of the mold. Injection molded parts are fixed by extendable cores, ejector pins or pawl during transfer.

The dividing plate discussed earlier has been simplified into a central support that rotates with the injection molded part and then proceeds with injection molding. Central scaffold molds usually employ hot runner systems. One advantage of it over the indexing plate system is that the self-weight of the rotating system is smaller, allowing it to rotate or swing rapidly, thereby significantly reducing the forming cycle of the system.

The molding of injection molded parts can be accomplished by the injection side or the ejection side. It is grasped by a telescopic core during displacement and then pushed out from a central hole.

5. Turntable system

Multi-component molds using turntable systems have been widely applied in various fields of the plastic industry. Depending on different application scenarios, the turntable can be driven by hydraulic power or a motor. Using a turntable system is the most effective solution for the mold to rotate from one injection position to the next. The rotation of the mold is accomplished by the turntable, making the mold simpler.

Depending on the number of injection molding components, the positioning of the turntable can be divided into 4×90°, 3X120° or 2X180°. Among them, the simplest is to rotate the turntable 180° to the left or right. The feature that the moving die can rotate continuously in one direction is particularly suitable for multi-station molds. As the mold needs to rotate continuously, cables and

The connection of hoses, the supply of cooling water and hydraulic oil will become quite complicated.

Compared with other multi-component molds, one drawback of the turntable system is that it requires a larger injection molding machine. Generally, the length of the machine guide rails in a turntable system needs to be increased by 200mm, and the distance between the guide rails needs to be increased by 50 to 100mm.

6.bucket lifting mold

In a broad sense, the working mode of bucket lift molds and transfer injection molding technology is similar. The production is transferred from an integrated screw mechanism to the next injection molding station.

The highlight of this mold technology is that the multi-component injection molding machine used does not require special specifications. The mold will be slightly longer than the rotating mold, but it doesn't need to be rotated. In this way, there is no need to enlarge the template or increase the length of the guide pins of the injection molding machine.

The pre-molded part is moved to the next station through a screw. Then, the product undergoes injection molding and is transferred to the unloading station outside the mold. The mechanical hand takes down the finished product during the injection molding stage, and the injection molding cycle will not be affected.

The empty half mold is sent back to the injection molding station again. During the mold opening stage, the second screw moves the half mold from the unloading station to the pre-plasticizing station. In this way, the bucket lifting cycle is completed and a new cycle begins anew.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

7-cubic-meter stacked mold technology

The advantage of cubic mold stacking technology over other mold technologies lies in the fact that with the same size of machine, the number of cavities in the mold can be doubled. In other words, for the same order volume, the size of the machine can almost be halved.

7.1 Cubic rotary mold stacking technology

When applying the rotary die stacking technology, the rotation of the mold is accomplished by a horizontally rotatable central module.

The pre-plastic part is first formed on the first parting surface. When the mold is opened, the pre-plastic part remains on the central rotating module. When the mold is fully opened, the central module rotates 180° to the second profile surface. After the mold is closed again, the second component of the plastic is injected into the second cavity containing the pre-molded part.

By applying a 4×90° rotating cubic die, secondary processing can be carried out simultaneously at the second station (operator side) and the fourth station (non-operator side). For instance, the second station is used for cooling injection-molded parts, while the fourth station is for the mechanical hand to pick up the products. The two processes are carried out simultaneously without affecting the molding cycle

Impact. Alternatively, the second station can also be used for in-machine or out-of-machine assembly (in-mold assembly).

7.2 Double Cubic rotating Die Stacking Technology

The double cubic stacked mold is placed between the moving and fixed half molds, and two sets of rotating stacked molds are also configured. In principle, a double-cubic stacked mold is like two independent molds working simultaneously. It has three clamping surfaces and all forming processes are carried out simultaneously, which makes the production of complex parts highly efficient.

Compared with traditional molds, when the assembly process needs to be transferred to the mold, the double cubic stack mold has a significant advantage, and the molding cycle will also be greatly reduced. Assembly processing can be carried out simultaneously with injection molding. More and more assembly processes have been transferred to in-mold operation. Because the products assembled in the mold have higher precision.

The preferred application fields of double cubic stacked molds include packaging, medical care and the automotive industry. With one process, the integration of two or more packaging components can be achieved.

8. Sequential mold stacking

Sequential mold stacking involves two sets of molds being connected back to back, with plastic filling each mold cavity in sequence and the molds being opened in a cycle.

In a common mold, the cavities on the parting surface stand opposite to each other. They are filled simultaneously during each injection molding, and the finished products are demolded at the same time when the mold is opened.

However, in sequential die stacking, the parting surfaces open alternately. That is to say, when half of the mold cools down, the other half of the mold is just demolded and re-injected. During the idle time of mold cooling, the next injection molding stage can be carried out. When the two semi-molds work in sequence, different injection molded parts of the same product series can be produced. Therefore, injection molding machines must be equipped with special programs to provide the appropriate amount of plastic required for each parting surface.

Thick-walled parts with longer cooling times are also particularly suitable for this technology.

The external edge lock mechanism enables the two semi-molds to operate alternately. The function of the side lock is similar to that of a rack and pinion system. By using a single adapter board, two ready-made molds can be transformed into a set of sequential stacked molds.

9.component molds for thermosetting plastics and elastomers

In thermosetting multi-component molds, thermosetting plastics are rarely paired with thermosetting plastics. In most cases, two types of materials, soft and hard, are used in combination. However, there are also examples of combinations of thermosetting plastics and high-temperature resistant thermoplastic central support rotary process indexing sheet materials.

Elastomers can be combined with thermoplastics and thermosetting plastics. In both cases, the pre-molded parts should be made of hard plastic.

The combination of thermosetting plastics and elastomers is mostly used in the field of engines. Both of these plastics have the characteristics of good thermal stability, resistance to engine oil and fuel oil. Therefore, thermosetting plastics and elastomers [usually nitrile rubber (NBR)] with very similar material classifications can be combined very well. The temperatures at which these two materials are produced using heated molds are also at the same level. The difference between them lies in that thermosetting plastics need to be hardened to become elastic

The body needs to be vulcanized.

The combination of soft and hard plastics can be used to improve the sense of touch or absorb vibrations. Examples of improving tactile sensation through the combination of soft and hard plastics include small devices such as hand drills, welding guns or hair dryers. Such a combination can be used in automotive engineering and engine technology to selectively absorb vibrations.

Related News

Injection mold commonly used six kinds of mold materials

2025-06-19

The choice of steel not only affects the service life of the mold, but also affe...

Key equipment in the field of logistics and warehousing

2025-06-29

Key equipment in the field of logistics and warehousingTray mold Manufacturer in...

Performance characteristics and selection criteria of injection molds

2025-06-30

Performance characteristics and selection criteria of injection molds This ...

Basic processing items and requirements for mold base

2025-09-30

Basic processing items and requirements for mold base(1) Fixed mold A plate and ...

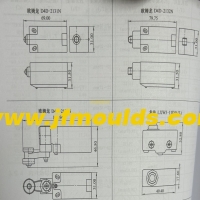

The limit switch of the mold

2025-10-08

The limit switch of the mold In some cases, the actions of different mechan...

Surface roughness of mold-formed parts

2025-10-13

Surface roughness of mold-formed partsI. Representation Methods and Meanings of ...