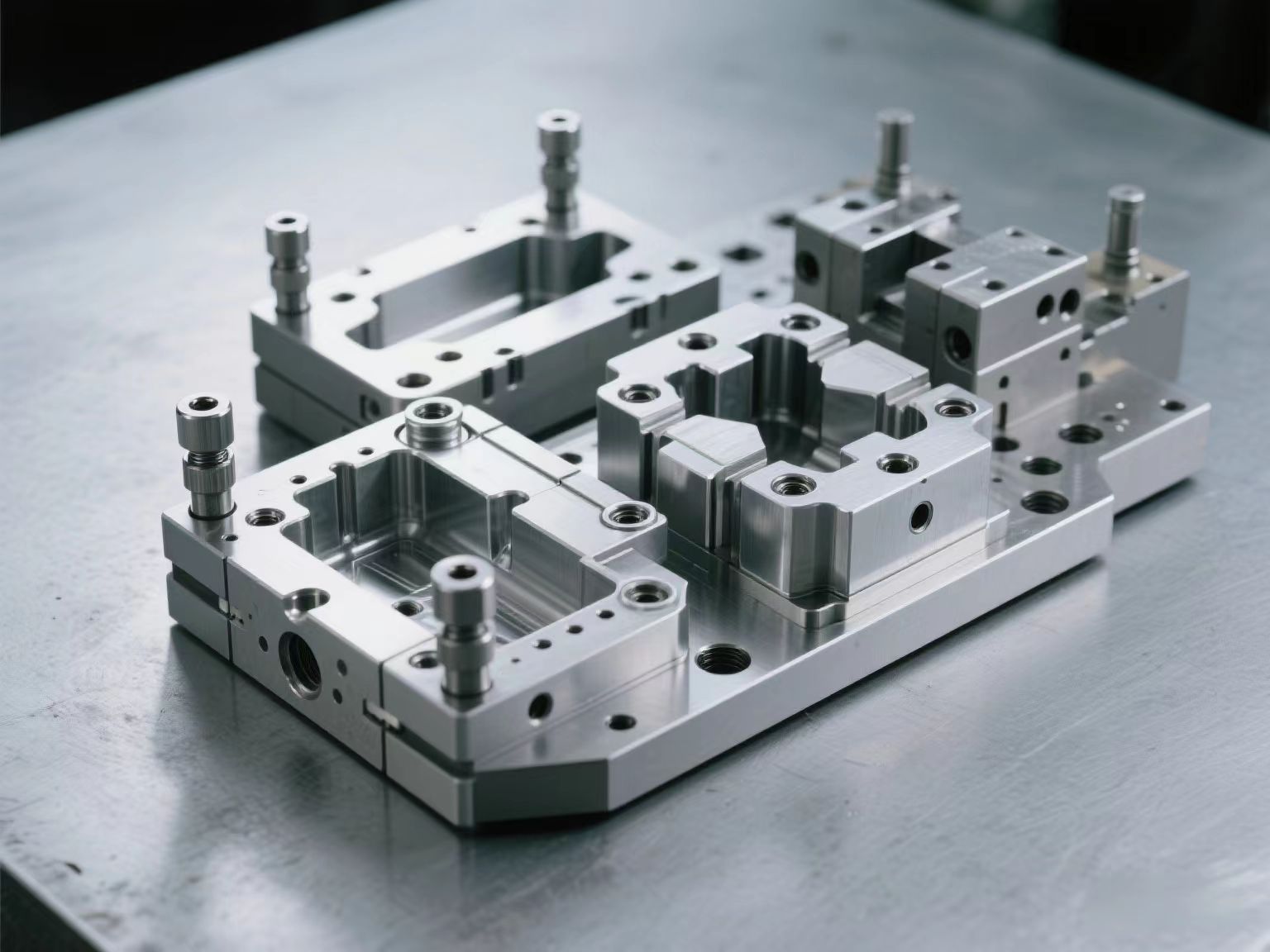

Multiple mold designs

Multiple mold designs

In-mold labeling process

Thin-walled plastic packaging products and debit cards are the main application fields of in-mold labeling (IML) technology. The production of labeling injection molded parts is completed in one step by placing pre-printed films in the mold.

In the in-mold labeling process, pre-punched decorative labels are placed in the mold cavity for back injection (i.e., plastic is injected from the driven mold side - Translator's note). The labels are supplied from the label library to the mold cavity by the mechanical hand. The labels are vacuum-sucked by the mechanical hand gripper and fixed in the mold cavity by vacuum or electrostatic means.

The high temperature caused by friction at the glue inlet may damage the label. Therefore, the mold design should take into account the selection of a suitable needle valve system. The label needs to have a certain degree of hardness to facilitate stable grasping.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

2. Cascade injection molding process

In cascade injection molding, the hot runner gates are filled step by step one after another.

This technology is applicable to situations where the plastic flow path is long or high-viscosity plastics need to be processed.

The plastic flow path is divided into several sections, each of which is injected by a needle valve type hot runner nozzle. In cascade injection molding, multiple hot runner nozzles do not inject simultaneously but open and close one after another in sequence. The filling of the injection molded part is also carried out in sections.

The raw materials continue to flow until the injection molded part is fully filled. The holding pressure begins and is evenly loaded onto each nozzle.

The wall thickness of the product along the plastic flow path and the melt index (MFI) of the plastic determine the magnitude of the pressure inside the mold. Multiplying this pressure by the area of the injection molded part can calculate the required clamping force (refer to the tension of the mold in Section 1.4). From this, it can be concluded that the clamping force of the machine is always equal to the tension of the product being expected.

Cascade injection molding is mostly used in the manufacturing of automotive products. Typical products include bumpers and tailframes. Cascade injection molding is not suitable for manufacturing optical products because marks of pressure switching are prone to appear on the products.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

3. Core fusion injection molding technology

Products with hollow and complex geometric shapes can be produced by core melting technology, in which case the mold core is no longer drawn out by the sliding fire.

In this method, the core, which is the inner cavity of the injection molded part, is die-cast from drill alloy. This core is placed into the mold for injection molding.

If the core wrapped in plastic material and located inside the injection molded part needs to be removed, the injection molded part can be immersed in hot water at 80 ° C. Since the melting point of the alloy is 70℃, the core melts immediately.

The molten alloy forms beads at the bottom of the water tank and can be reused as a new type of core once dried. Because the surface of the secret alloy is clean and smooth during die-casting, the interior of the injection molded part also looks as smooth as if it had been polished.

As an alternative to the core melting method, the upper and lower shells can be injection-molded first, and then glued or welded together. This is a more economical solution.

One of the main applications of the core melting method is intake manifolds in the automotive industry, cooling water and gasoline delivery components for passenger vehicles, as well as pump casings, paddles and bathroom products.

4. According to the definition of the Stuttgart Institute for Precision Engineering Design and Production in Germany, there is a difference between injection-molded parts and microstructure components.

Microstructure parts

Microstructure parts are injection-molded components with normal dimensions, but they have single-sided or double-sided microstructure areas, and their overall weight is only a few grams. The most well-known are the data of CDS and DVDS

Storage medium.

5.injection molded parts

There are millimeter levels. The injection weight of such a tiny cavity of a microinjection molded part is at the milligram level, and its size is almost impossible to be processed by traditional methods, such as milling or electro-corrosion processing (EDM). The cavity can only be processed by electroplating or etching, especially suitable for the processing of X-ray LIGA technology (plate electroplating method).

The temperature of plastic materials and molds has a decisive influence on the quality of micro-injection molded products. The mold needs to be heated by an additional heater. After injection molding is completed, the cavity cools to the demolding temperature. This process is called variable temperature process control. Another important criterion for producing high-quality products is that the cavity has good venting during the injection molding process. If this cannot be guaranteed, the material will be scorched and black spots will form.

Micro-injection molded parts are particularly suitable for the watch industry, communication technology, medical and biotechnology, as well as sensor technology fields.

Related News

The methods for adjusting parameters for defects in injection molded products are as follows

2025-08-01

The methods for adjusting parameters for defects in injection molded products ar...

Design of the external dimensions of mold-formed parts

2025-10-11

Design of the external dimensions of mold-formed parts According to the ext...

The causes and solutions of dents on injection molded products, incomplete finished products, and flash on products

2025-07-29

The causes and solutions of dents on injection molded products, incomplete finis...

The screw columns of the mold are prone to damage and weld marks/shrinkage

2025-08-07

The screw columns of the mold are prone to damage and weld marks/shrinkageThe sc...

The surface of the mold is baked and printed bright and has surface flow marks

2025-08-02

The surface of the mold is baked and printed bright and has surface flow marksTh...

Define a new paradigm for the injection mold industry through technological breakthroughs and ecological reconstruction

2025-07-04

Define a new paradigm for the injection mold industry through technological brea...