Tolerance and fit of injection molds

Tolerance and fit of injection molds

I. Common tolerances and fits of parts in injection mold assembly drawings

Injection molds often adopt precision grades of IT5 to IT8 based on the precision requirements of the plastic parts, the service life of the mold, and the functions of the mold components.

Two: Tolerance of injection mold forming dimensions

(1) Mold size classification

The dimensions of molds are classified into three types according to the actual situation of the mold structure: forming dimensions, composition dimensions, and structural dimensions. Among them, the dimensions related to the forming surface of the formed plastic part or sprue are called forming dimensions. The dimensions related to the wire clamping on the surface of plastic parts or spout are called composition dimensions. All other dimensions that have no direct relation to the formed plastic parts or spout are collectively referred to as structural dimensions.

(2) Structural dimensions

① General tolerances of structural dimensions. The general tolerances of structural dimensions in the technical documents of common molds and precision molds, including linear dimensions and angular dimensions, shall be implemented in accordance with the tolerance grade of precision grade as stipulated in the national standard GB/T1804--2000 "General Tolerances - Tolerances for Linear and Angular Dimensions Not Specified".

② Deviation in the marking of structural dimensions

When the structural dimension mating parts are purchased parts, the mating relationship should be reasonably determined within the range of cost and manufacturing capacity, taking into account the mold requirements and the dimensional limit deviations of the purchased parts provided by the supplier (for example, the mating of pins and pin holes), to set the dimensional tolerance range of the self-made parts.

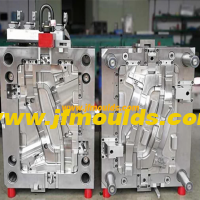

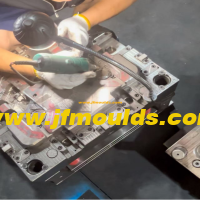

Automobile parts mold Manufacturer in China (jfmoulds.com)

a. The structural dimensions are based on the fit of inserts

For common molds and precision molds: when the basic size is 18mm, H8/h7;

When the basic size is 18mm to 80mm, it is H7/h6.

When the basic size is 80mm to 500mm, it is H6/h5.

b. The structural dimensions are sliding fits (for example, the fit between row positions and row position presses, the fit between inclined top sliders and ejector pins)

For common molds and precision molds: when the basic size is 18mm, H8/g7;

When the basic size is 18mm< 50mm, H7/g6;

When the basic size is 50mm<L250mim, H6/g5

When the basic size L is greater than 250mm, the configuration fit is adopted,H6/g5 MF(the first processed part is the hole).

(3) Composition dimensions

When the mating parts that make up the dimensions are purchased, the fit relationship should be reasonably determined within the cost and manufacturing range (for example, the fit between the ejector pin and the ejector pin hole), taking into account the mold requirements and the dimensional limit deviation of the external components provided by the supplier.

① The composition size is the fit of the insert (for example, the fit between the mold meat and the insert)

Common mold: When the basic size is 50mm, H7/js7

When the basic size is 50mm< 250mm, H7/k6;

H6/h5MF(The first processed part is a hole)

When the basic size is 250mm to 630mm, a formulated fit is adopted.

Precision molds: When the basic size is 30mm, H7/js7;

When the basic size is 30mm< 180mm, H6/js6

When the basic size is 180mm to 400mm, a configuration fit is adopted, with H6/h5MF (the first processed part is the hole).

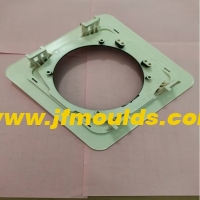

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

② The composition dimensions are sliding fits (for example, the fit between the mold meat and the inclined top, the fit between the mold meat and the straight top)

Common mold: When the basic size L<10mm, H7/g7;

When the basic size is 10mm to 30mm, it is H7/g6.

When the basic size is 30mm< 50mm, H6/g5;

When the basic size is between 50mm and 120mm, the configuration fit is adopted, H6/g5 MF(the first processed part is the hole).

Precision molds: Basic dimensions [18mm, H6/g6;

When the basic size is 18mm to 30mm, it is H6/g5.

When the basic size is 30mm< 80mm, the fitted fit is adopted, H6/g5 MF(the first processed part is the hole).

(4) Forming dimensions

The cavity forming dimensions of both common molds and precision molds are required to be calculated based on the intermediate value of the corresponding dimensions on the plastic part products, so as to fluctuate in the positive and negative directions during the manufacturing process, that is, the upper and lower deviation values of the forming dimensions are half of their tolerance values. The above regulations do not take into account the plastic shrinkage rate and other special circumstances. The specific values of the forming dimensions can be found in the forming dimensions of the mold cavity and the limit deviation of the unmarked tolerance dimensions of the mold cavity arc.

Related News

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakthroughs

2025-07-15

Exploring the Full Life Cycle of Injection Molds and Thoughts on Industry Breakt...

Surface treatment of molds

2025-07-26

Surface treatment of molds1. Common surface treatment processes The purpose o...

Injection molds: The "Industrial Gene" Hidden Behind Everything

2025-07-12

Injection molds: The "Industrial Gene" Hidden Behind Everything When our fing...

The causes and solutions of poor welding in injection molding, product cracks and product deformation

2025-07-30

The causes and solutions of poor welding in injection molding, product cracks an...

NowOn behalf of the manufacturing industry precision "molding magician"

2025-06-29

NowOn behalf of the manufacturing industry precision "molding magician" In today...

The glue inlet position of the mold is dragged and charred

2025-08-06

The glue inlet position of the mold is dragged and charredThe glue inlet of the ...