Special mold design

Special mold design

1 Stacked mold

The stacked mold simultaneously produces injection molded parts from two parting surfaces, while the traditional single-layer parting surface mold can only take out the product from one parting surface. This means that the number of products produced by die stacking has almost doubled.

In principle, the stacked mold consists of two ejection systems and a set of centrally placed sleeve plates. This set plate system includes a hot runner and gating systems on the left and right sides. The hot runner, on the other hand, is supplied with molten plastic by a central gate sleeve, known as a "submersible pipe", or by two sets of back-to-back valve needle hot runner gates.

The synchronous reciprocating motion of the center plate is performed by the rack system. The parallel guidance between the half molds is accomplished by the machine tool's green column. Given the self-weight of the stacked formwork, the guidance and support of the formwork are of great significance. For molds with extremely large dimensions and volumes, additional supports are required between the central sleeve plate and the machine tool bed.

The design of the stacked mold is usually modular. This enables the cores of the same product series to be replaced quickly and effectively, such as those of containers of different sizes.

The same clamping force can double the output of the stacked mold. The use of stacked molds only makes sense when there is continuous production of large quantities of products.

Elastomer mold stacking

The die stacking technology using two parting surfaces and cold runners can increase product output by more than 70%. As there is no need to add another injection molding machine, energy consumption is also significantly reduced. The production of laminated molds mainly uses machines with a clamping force of 3000 to 10000N [approximately 300 to 1000 tons of clamping force (Translator's note)

The temperature of the gating system for cold runner gates should not exceed 60° C. The production temperature of elastomer materials must be lower than their vulcanization temperature. The heating of the mold's template, inserts and core is all electrically heated.

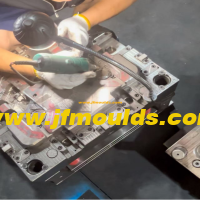

Automobile fuse box Manufacturer in China (jfmoulds.com)

2. Thin-walled molds

Thin-walled molds are basically high-speed molds used in the packaging industry. The typical wall thickness of injection molded parts is less than 1mm.

Thin-walled technology has special requirements for molds. Due to the fast production cycle and high output of the products, the selection of mold steel, the centering and positioning of the core, and the venting during injection molding are all particularly important.

For instance, on a multi-cavity mold, a so-called floating core with a larger base is applied, which can compensate for the thermal expansion caused by the core's heat generation. The mold base must be made of pre-hardened steel, while the mold inserts (fixed mold core and cavity) need to be fully quenched.

For injection-molded parts with a relatively short molding cycle, the key quality point lies in the exhaust efficiency during the injection molding stage. Depending on the product, the gas generated in high-speed injection molding must be discharged from the cavity within 0.1 seconds. Therefore, exhaust slots must be provided on the parting surface around the cavity. Experience shows that a trough with a depth of (0.5 to 1) ×10mm and a width of 3 to 4mm can meet the requirements for gas discharge. If the exhaust aspect is not well considered, the plastic material is at risk of being scorched.

Thin-walled parts are ubiquitous in the packaging and communication industries. Typical applications include packaging boxes with a wall thickness of less than 1mm, such as yogurt cups, butter boxes, ice cream boxes, mobile phone cases, and plant packaging boxes with a wall thickness of only about 0.4mm.

3. Insert injection molding technology

In insert injection molding technology, non-plastic materials, such as metal parts, are often placed in molds and formed by plastic cladding.

In most cases, insert injection molding is carried out on vertical injection molding machines. These machines are often equipped with a movable or rotating worktable. The basic form of this type of mold is composed of an upper half mold and several lower half molds. Therefore, it can take out the finished product when the machine closes the mold, and at the same time insert new inserts into the already empty lower half of the mold, thereby avoiding the loss of the molding cycle.

The most complex part of insert injection molding technology is how to automatically feed inserts and fix the "non-plastic parts", which are usually made of metal, in the mold. With the appropriate mechanical hand device, this process can be fully automated.

Inserts are often equipped with upsets, grooves and kimmings, which are designed to ensure a permanent fit with the plastic.

Common electrical and medical technology applications include threaded guide sleeves, plug contacts, cables, screwdriver handles, and subcutaneous injection needles, all of which are typical products of insert injection molding.

4. Push-pull injection mold

In a push-pull injection mold, two streams of molten material of one type of plastic are injected into the mold in opposite directions.

If there are two or more gates on the plastic part, the product's strength will be weakened due to the presence of weld lines, and weld lines will occur when two streams of material meet in the mold. Although the edges on both sides will permeate each other, it will still cause structural damage at that location.

The formation of weld lines can be prevented through the counter-flow of plastic during the push-pull injection molding process. The mold cavity is provided with two gates, and the most ideal gate positions are on opposite sides of the mold.

Injection molding unit 1 fills the mold control through gate 1, thereby pressing the plastic into injection molding Unit 2 through the second gate.

After the push-pull process begins, injection molding unit 2 injects injection molding unit 1 again, pushing the material back to injection molding Unit 1 through the injection molded part.

This process is repeated until the product without any fusion lines is formed.

The push-pull injection molding process has significantly improved the quality of products containing glass fiber materials and new materials, such as liquid crystal polymers (LCP) and polyetheretherketone (PEEK).

Car Lamp Mold Manufacturer in China (jfmoulds.com)

5. Implantation injection molding

Implant injection molding technology is similar to the cascade injection molding process, but it uses two types of plastics for injection molding.

When another material needs to be injected onto or in the middle of a large-area injection molded part, implant injection molding can come in handy. This technology can only be used when the second raw material does not require a clear boundary. Where the two original materials converge depends on the amount of time delay in the injection of the second material. Therefore, the boundary positions of the two materials are not fixed.

This type of mold has a relatively simple structure. The only difference from the traditional cascade mold is that it is equipped with another set of hot runners for the second raw material. Although the boundary line between the two materials appears randomly, it is still a two-component injection molding process. In addition, injection molding does not require a turntable.

A typical application field is the engine hood cover, which requires vibration absorption and elastic support.

Related News

Injection molds: The "Industrial Gene" Hidden Behind Everything

2025-07-12

Injection molds: The "Industrial Gene" Hidden Behind Everything When our fing...

Design of the external dimensions of mold-formed parts

2025-10-11

Design of the external dimensions of mold-formed parts According to the ext...

Types and basic requirements of mold design drawings

2025-09-07

Types and basic requirements of mold design drawingsTo shorten the production cy...

How to solve the problems of surface dents and mold on injection molds

2025-08-05

How to solve the problems of surface dents and mold on injection moldsConcave po...

Solutions to the problem of easy breakage at the junction of the mold's appearance color difference and material flow

2025-09-05

Solutions to the problem of easy breakage at the junction of the mold's appearan...

Injection mold gate technology

2025-07-23

Injection mold gate technologyGating systemAuto Mould_Taizhou Jiefeng Mould Co.,...