The selection of mold base specifications and models

The selection of mold base specifications and models

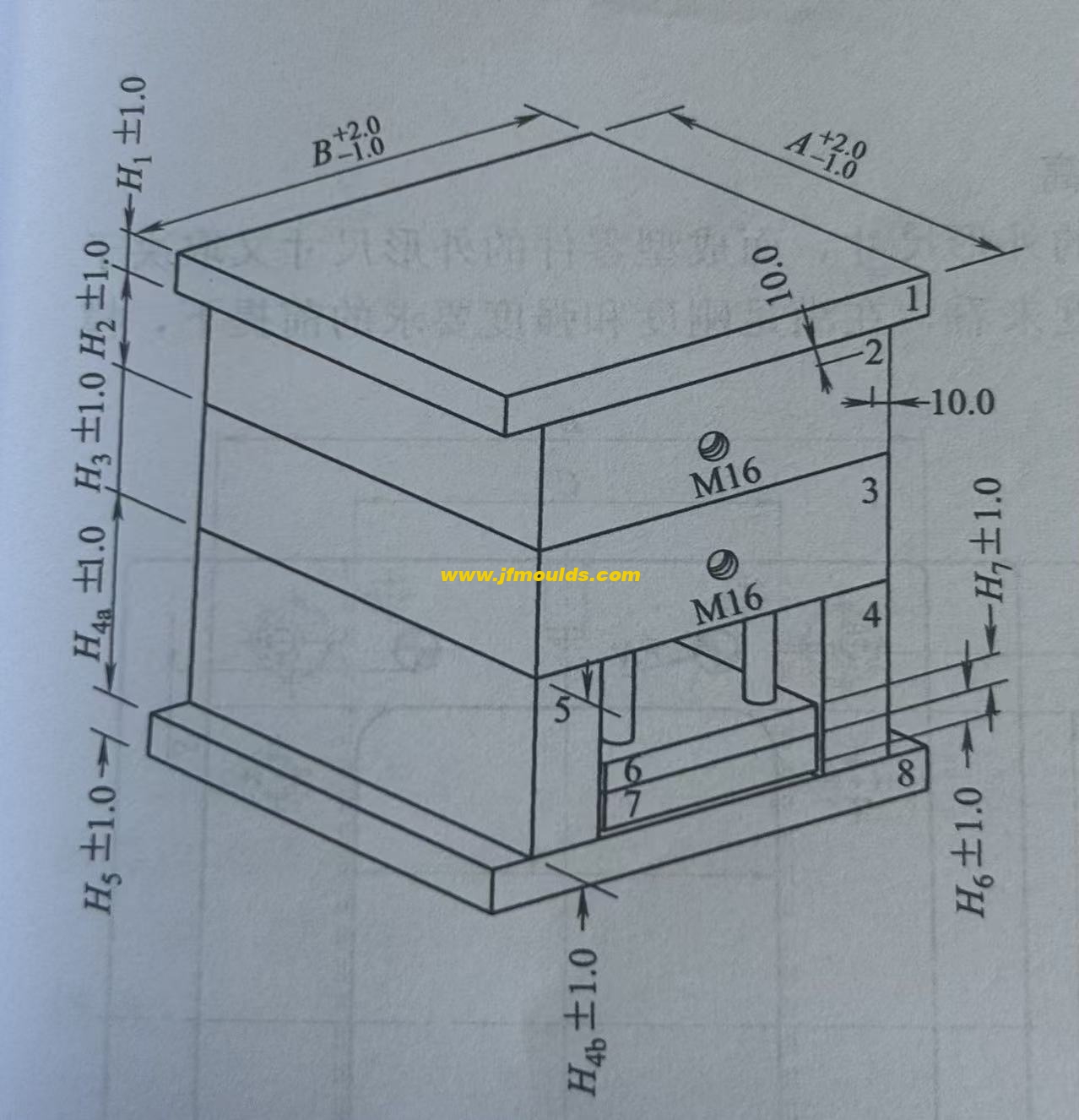

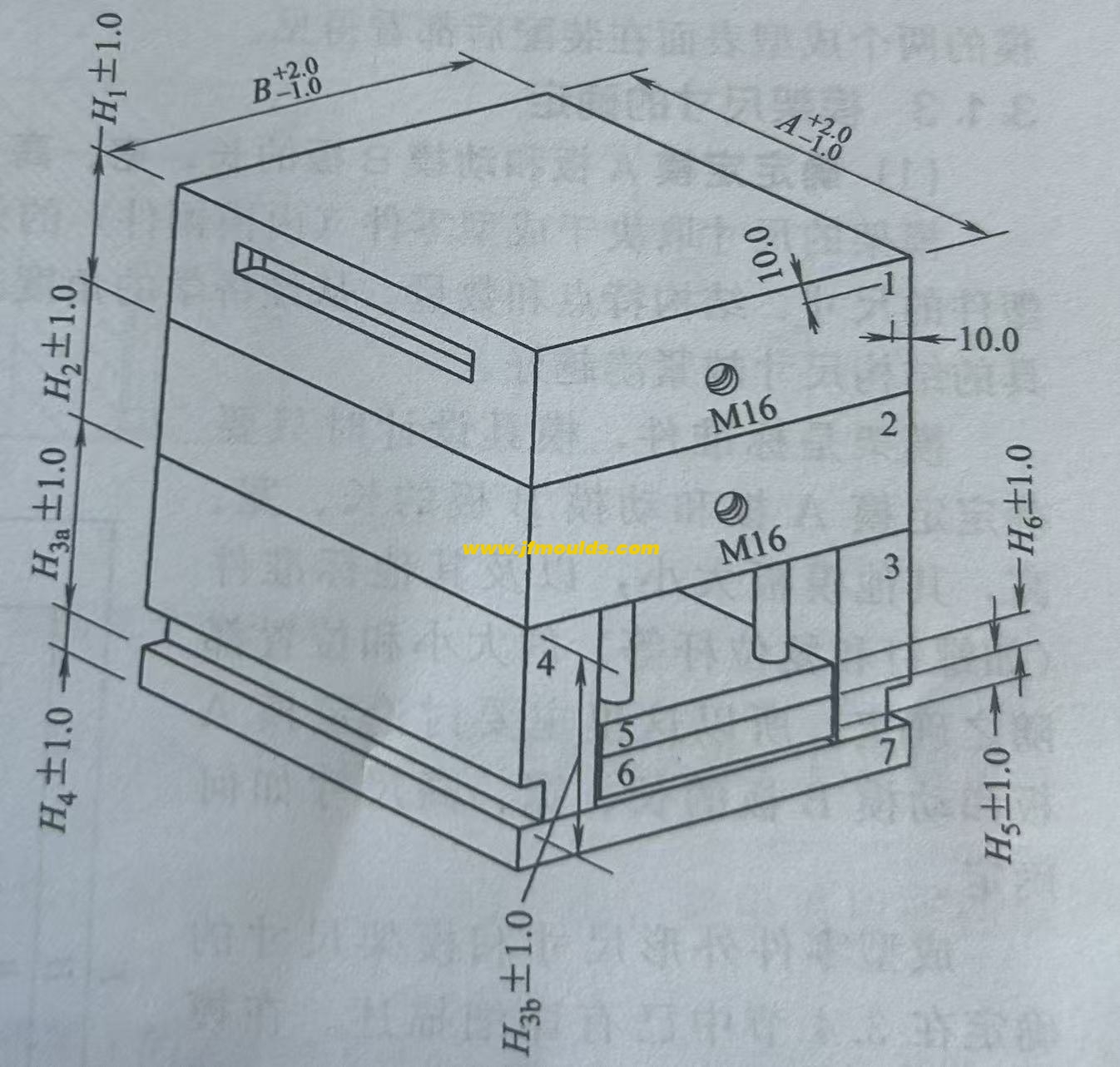

(1) Selection of two-plate mold base and three-plate mold base

1. When you can use a two-plate mold base, you do not use a three-plate mold holder. Because the structure of the two-plate mold base is simple, the manufacturing cost is relatively low, while the structure of the three-plate mold base is more complex, and the probability of failure of the mold during the production process is also high.

2. When the plastic part must be fed from one or more points in the middle of the cavity with a point gate, a three-plate mold base is selected. The following situations are fed with point gates.

a. The projection area of the molded plastic parts on the parting surface is large, and the single cavity requires multiple feeds.

B. One mold with multiple cavities, among which there is one of the following suitable point gates: some plastic parts must be fed from multiple points in the middle, otherwise it may cause deformation or insufficient filling of plastic parts; plastic parts require intermediate pouring, otherwise it may be trapped or insufficiently filled, which will affect the appearance; The size of each cavity is very different, and when using the side gate mold base, the gate sleeve should be large off-center, and it is easy to produce flash or deformation during mold production.

c. Plastic gears, most of them use point gates, and in order to improve the size progress of gears, three-point feeding is often used. Multi-cavity toy tires often use pneumatic forced demolding, and the gating system is a point gate to ring gate.

d. For plastic parts with small wall thickness and complex structure, the melt has a large flow resistance in the mold, and it is difficult to fill or ensure the molding quality with side gates.

e. For cylindrical, box-shaped or shell-shaped parts with too high height, the use of point gates is conducive to exhaust, which can improve the molding quality and shorten the molding cycle.

3. The hot runner mold is equipped with a two-plate mold mold base.

Car grille mold Manufacturer in China (jfmoulds.com)

(2) Selection of standard three-plate mold base and simplified three-plate mold base.

1. The minimum dimensions of the three standard mold bases in Longji mold base are as follows:

a. The minimum size of the water outlet mold base is 200mm×250mm;

B. The minimum size of the simplified water outlet die base is 150mm×200mm;

c. The minimum size of the large water outlet mold base is 150mm×150mm.

In other words, if the mold base is less than 200mm× 250mm cannot be used with a standard three-plate mold mold base.

2. The simplified three-plate mold base has no push plate. If the plastic parts need to be pushed out with a push plate, a simplified three-plate mold holder cannot be used.

3. When there are large side core pulling sliders on both sides, the standard three-plate mold base can reduce the width of the mold base and the mold with high life requirements, and the standard three-plate mold base should be used.

4. Oblique slider mold, when the slider pops up, it is easy to collide with the short guide column, at this time, the width of the mold base can be reduced with a simplified three-plate mold mold base.

5. The accuracy and rigidity of the standard three-plate mold base are better than the simplified three-plate mold base, so the standard three-plate mold base should be used for molds with high precision requirements and high life requirements.

6. For molds with lateral core pulling mechanisms, there must be at least one mold opening surface on the mold setting, so even the side gate gating system usually adopts the GAI type or GCI type in the simplified three-plate mold mold base.

Commodity Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

(3) Selection of I-mold base and straight mold base

Therefore, the mold is divided into I-shaped die and straight die according to needs; Usually the two-plate die mostly uses a straight die base, while the three-plate die usually uses an I-shaped die base.

In addition, when the mold width is less than 300mm, it is advisable to choose an I-shaped mold base; When the width of the mold is greater than or equal to 300mm, it is advisable to choose a straight mold base. For the two-plate mold base, the width of the mold base is greater than or equal to 300mm, and when the fixed template is to open the frame, a straight mold base with a panel (T-shaped) can be used.

The straight mold base must be machined with the mold groove. The size of the code mold slot is standardized, and users can also design or process it themselves according to their needs.

The edge of the I-shaped mold base with a mold width of less than 450mm is 25mm higher on one side, and the edge of the I-shaped mold base with a mold width of more than 450mm (including 450mm) is 50mm higher on one side. When choosing a straight mold base, the width of the mold base is 50mm or 100mm smaller, and the matching injection machine can be smaller.

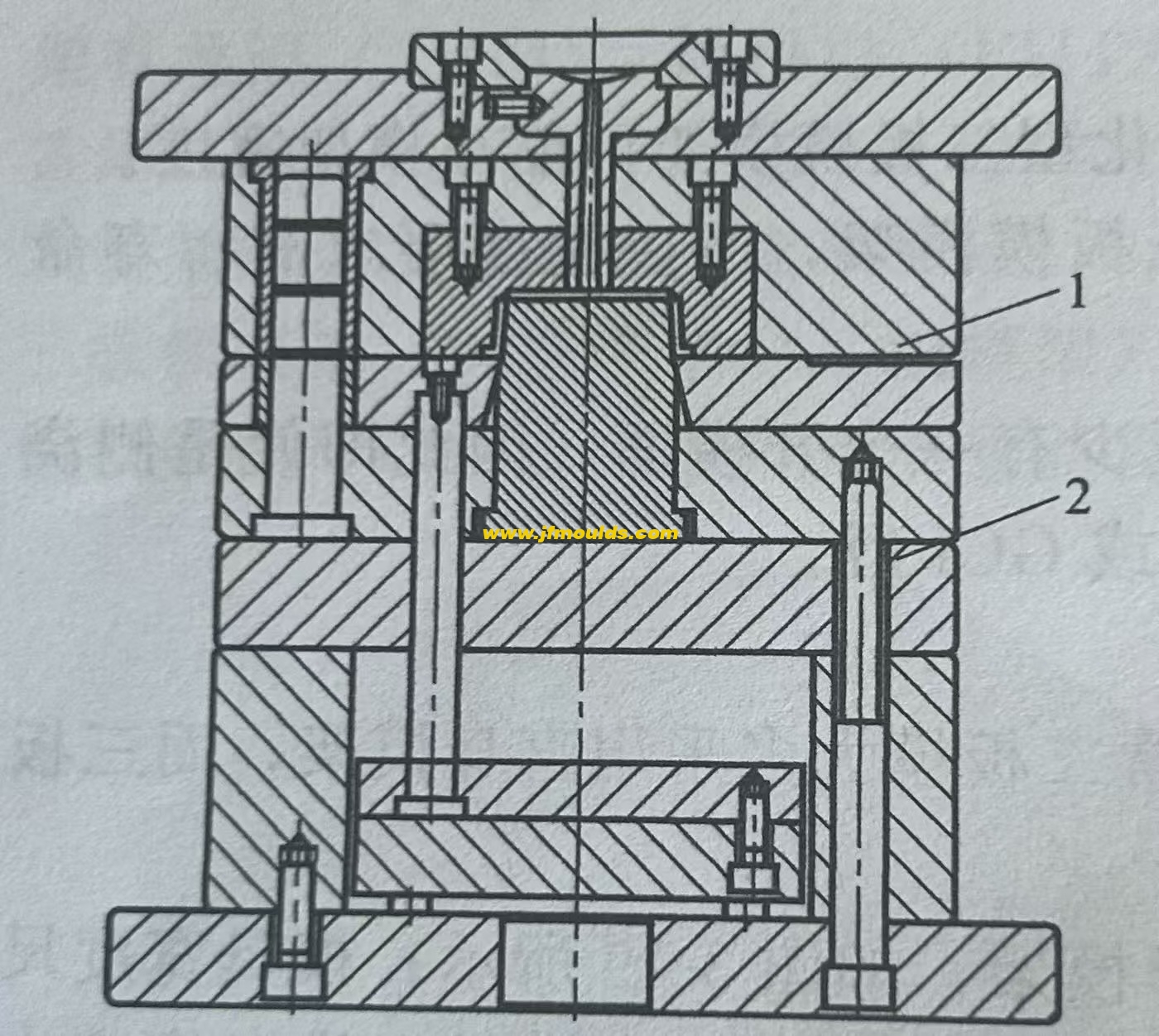

(4) The mold base should use a bracket

The pallet is assembled under the moving mold B plate. There are usually two situations where a pallet plate is needed.

1. The moving mold B plate opens the frame. When the hole for assembling the inner die insert is processed into a through hole, it is commonly known as the open frame. When the inner mold insert is round, or the movable template is very deep, it is advisable to open the frame. The mold frame with a lateral core pulling mechanism or an oblique slider should not open the frame.

2. False three-plate mold, when the support plate and B plate of the moving mold part need to be separated before the plastic part is launched, commonly known as the false three-plate mold. The support plate and moving template in the false three-plate mold should be separated before the plastic parts are launched, at this time the guide column is installed on the pallet, and the guide sleeve is installed on the moving template. False three-plate mold is often used in the case of internal core pulling or oblique core pulling of the moving mold (the locking block and the inclined guide column are installed on the pallet plate to choose the mold base with the support), so that the plastic part needs to be forcibly demolded (the moving model core is first separated from the plastic part), otherwise there is no need to add a pallet. The thickness of the pallet is standardized.

(5) The mold base should use a push plate

The push plate belongs to the push part, which is customs clearance = pushing the periphery of the plastic part too much, so as to push the plastic part away from the mold. Push plates are generally used in the following two situations.

1. The molded plastic parts are thin-walled, deep-cavity plastic parts, which are pushed out by push plates or push plates and push rods, which are stable and reliable.

2. There are no traces of pushers on the surface of the molded plastic parts, and the push plate must be used. This type of plastic part includes transparent plastic parts, or the two molded surfaces of the moving and fixed molds are visible after assembly.

Related News

The lateral core-pulling mechanism of

2025-10-19

The lateral core-pulling mechanism of "slider inclined guide column"I. Classific...

The innovative design and intelligent development trend of injection molds

2025-07-09

The innovative design and intelligent development trend of injection molds In...

Surface roughness of plastic parts and selection of injection molding machines

2025-09-18

Surface roughness of plastic parts and selection of injection molding machines1....

From the basics to applications, how does it affect our lives

2025-07-17

From the basics to applications, how does it affect our livesThe basic concepts ...

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of Change

2025-07-04

Panoramic Insight into the Injection Mold Industry: Forging Ahead in the Wave of...

Lock module and support column

2025-10-03

Lock module and support columnOne: Lock moduleThe function of the lock module is...