Surface roughness of plastic parts and selection of injection molding machines

Surface roughness of plastic parts and selection of injection molding machines

1. Surface roughness

Surface roughness is not a surface defect, such as weld marks, bubbles and scratches, etc.

2.When designing the surface roughness requirements, two basic requirements must be provided: the roughness parameter values and the sampling length during measurement. If the sampling length is not specified, the provisions of GB/T1031-2009 "Product Geometry Specification (GPS) Surface Structure Profile Method" shall be followed. When necessary, the processing texture, processing methods and processing sequence, etc. can be specified

3. The parameter values of surface roughness are obtained on the cross-section perpendicular to the measured surface. For a given measured surface, if the direction of the cross-section is consistent with the direction of the maximum value of the height parameter, the direction of the measured cross-section does not need to be specified; otherwise, it should be marked on the drawing

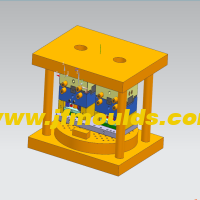

Hand-brewed coffee cup mold Manufacturer in China (jfmoulds.com)

4. The method for marking surface roughness shall be carried out in accordance with the provisions of GB/T131-2006 "Technical Drawing - Method for Marking Surface Features"

5. Surface classification of plastic parts. The surface requirements of plastic parts, based on actual conditions and customer demands, are divided into those with decorative patterns on the surface and those without. It can be further divided into transparent parts and opaque parts. And it is classified into exposed and non-exposed parts according to assembly and usage requirements, as well as parts that are difficult to demold (such as deep bone positions); The exposed surface (as per customer requirements) is divided into four types: anti-slip, polished, mirror finish, and with decorative patterns on the surface

6. Surface roughness of plastic parts. The specific surface roughness required for each type of plastic part should be determined based on the actual situation and the customer's requirements. The surface roughness of the mold cavity should reach the corresponding level. For details, please refer to the roughness requirements for the mold cavity surface in Chapter 1.

7. The surface roughness of plastic parts that can be achieved with different rubber compounds.

Two: Selection of Injection Molding Machines

The determination of the specification and model of an injection molding machine mainly depends on the size of the plastic part, the number of cavities and the batch size of the product. When choosing an injection molding machine, the main considerations include its plasticization rate, rated injection volume, rated clamping force, effective area for installing the mold (the distance between the pull rods of the injection molding machine), and ejection stroke, etc. If the specification and model of the injection molding machine to be used have been determined before the mold design, the designer must verify the installation dimensions and ejection stroke and other parameters of the mold. If the requirements are not met, either the number of cavities in the mold should be changed, the size of the mold should be reduced, or the customer should be consulted to replace the injection molding machine.

Auto Mould_Taizhou Jiefeng Mould Co.,Ltd. (jfmoulds.com)

1. Select the injection molding machine based on the rated injection volume

(Total weight of plastic parts in each cavity + concrete in the gating system) 80% of the rated injection volume of the injection machine.

2. Select the injection molding machine based on the rated clamping force

Assuming the sum of the projected areas of the plastic parts in each cavity on the parting surface is S fraction (mm), the rated (or nominal) clamping force of the injection machine is F lock, and the average pressure of the plastic melt on the cavity is type, then S fraction p type F is x 80%

3. Select based on the relevant dimensions of the installation part of the injection machine

The width of the mold must be less than the distance between the pull rods of the injection machine, that is, A>C, so that the mold can enter the injection machine

(4) Select based on the mold opening stroke

The ejection devices and maximum ejection distances of various models of injection molding machines are not the same. When selecting an injection molding machine, the opening stroke of the

injection molding machine's template should be adapted to that of the mold.

Related News

Injection molds: Specialized manufacturing, empowering new quality productivity in the industry

2025-07-14

Injection molds: Specialized manufacturing, empowering new quality productivity ...

In-depth Insights into the Injection Mold Industry: Technological Iteration, Market Landscape, and New Paradigms for Sustainable Development

2025-07-03

In-depth Insights into the Injection Mold Industry: Technological Iteration, Mar...

Entering the World of Injection Molds: An Analysis of Technology and Industrial Development from Multiple Perspectives

2025-06-28

Garbage can mold Manufacturer in China (jfmoulds.com)intotheWorldofInjectionMold...

Solutions for the rubber powder and inner side scratches on the sprue of the mold

2025-09-03

Solutions for the rubber powder and inner side scratches on the sprue of the mol...

Plastic parts

2025-09-15

Plastic partsOne: Dimensional accuracy of plastic partsThe dimensional accuracy ...

Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in molds

2025-08-15

Solutions to the problems of pin tip, pin shrinkage and trapped air fracture in ...